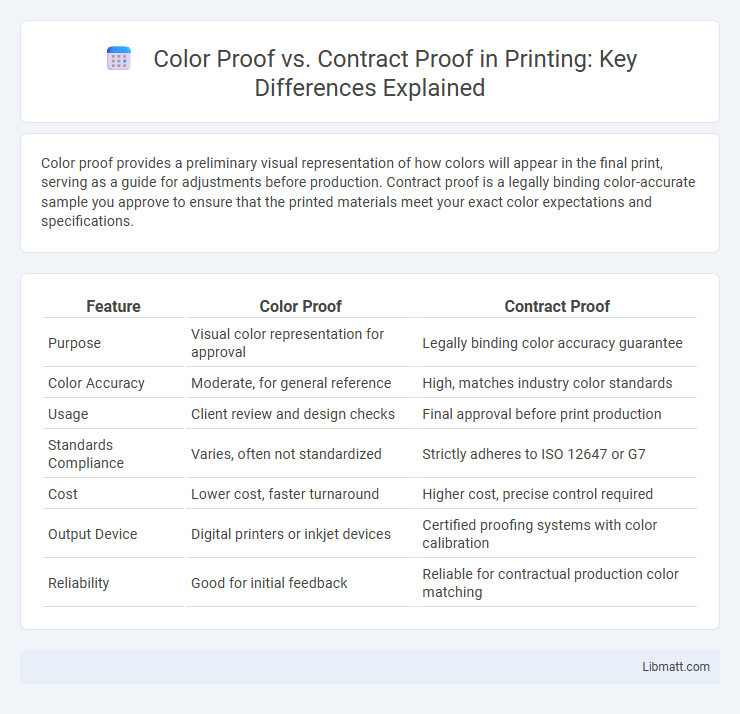

Color proof provides a preliminary visual representation of how colors will appear in the final print, serving as a guide for adjustments before production. Contract proof is a legally binding color-accurate sample you approve to ensure that the printed materials meet your exact color expectations and specifications.

Table of Comparison

| Feature | Color Proof | Contract Proof |

|---|---|---|

| Purpose | Visual color representation for approval | Legally binding color accuracy guarantee |

| Color Accuracy | Moderate, for general reference | High, matches industry color standards |

| Usage | Client review and design checks | Final approval before print production |

| Standards Compliance | Varies, often not standardized | Strictly adheres to ISO 12647 or G7 |

| Cost | Lower cost, faster turnaround | Higher cost, precise control required |

| Output Device | Digital printers or inkjet devices | Certified proofing systems with color calibration |

| Reliability | Good for initial feedback | Reliable for contractual production color matching |

Understanding Color Proof and Contract Proof

Color proof is a sample print used to preview and adjust colors before the final production, ensuring accurate color representation on different materials. Contract proof serves as a legally binding agreement between the printer and client, providing a precise color standard that all parties agree upon. Both proofs guarantee color consistency, but contract proof holds a formal role in quality control and dispute resolution.

Key Differences Between Color Proof and Contract Proof

Color proof serves as a visual reference to simulate how colors will appear on a final printed piece, primarily used for client approvals and design validation. Contract proof functions as a legally binding document in print production, ensuring color accuracy and consistency by meeting strict standards and tolerances defined by industry certifications such as ISO 12647. The key differences lie in their purpose: color proofs focus on visual approximation without guaranteed color fidelity, while contract proofs provide precise color matching that drives production decisions and quality control.

The Role of Color Proof in Printing

Color proof serves as a critical tool in the printing process to ensure color accuracy before full-scale production, allowing designers and printers to visualize the expected output on the chosen substrate. It provides a tangible representation of how colors will appear, helping to identify discrepancies and make necessary adjustments early on. Accurate color proofs reduce costly errors, maintain brand integrity, and streamline the workflow from design to final print.

What Is a Contract Proof?

A contract proof is a highly accurate color sample used as a final verification step before printing, ensuring color fidelity and consistency in the finished product. It serves as a legally binding agreement between you and the printer, specifying precise color standards that must be met. This proof is critical for avoiding costly errors and guaranteeing that the print run matches your expectations exactly.

Accuracy and Reliability: Color Proof vs Contract Proof

Color proof offers a visual representation of colors for reference but may vary in accuracy due to device calibration and lighting conditions. Contract proof ensures a standardized, highly reliable color match by adhering to industry specifications and printer profiles, serving as a binding agreement between client and printer. Choosing a contract proof guarantees your final output meets stringent accuracy and consistency requirements.

Industry Standards for Proofing

Industry standards for proofing distinguish color proof as a digital simulation used primarily for in-house color verification, while contract proof serves as a legally binding color agreement between clients and printers. Color proofs adhere to standards like ISO 12647, ensuring consistency in color reproduction during production phases, whereas contract proofs comply with stricter criteria under ISO 12647-7, guaranteeing precise color accuracy for final approval. The reliability of contract proofs as proofing standards underpins their role in minimizing disputes over color fidelity in print production workflows.

Workflow Implications of Each Proof Type

Color proofs provide a visual reference for color accuracy during the production process, enabling quicker adjustments in earlier stages of your workflow, while contract proofs serve as the legally binding standard between client and printer, ensuring final output meets agreed specifications. Using color proofs can streamline revisions and reduce delays, but relying on contract proofs guarantees consistency and reduces disputes in print production. Selecting the appropriate proof type impacts project timelines, quality control measures, and communication between creative teams and print vendors.

Cost Considerations in Proof Selection

Color proof systems generally offer lower upfront costs due to simpler technology and materials, making them suitable for preliminary design approvals. Contract proofs involve higher expenses as they require stringent quality controls, certified color accuracy, and specialized equipment to meet industry standards for final client approval. Budget allocation should weigh the necessity of precise color fidelity against project scale and timeline to ensure cost-effective proofing choices.

When to Use Color Proof vs Contract Proof

Color proof is ideal for early-stage design reviews and quick color assessments during the creative process, ensuring your visuals look accurate on standard output devices. Contract proof is essential for final approval before printing, providing a legally binding color guarantee that matches the production output under strict industry standards. When deciding which to use, rely on color proof to fine-tune colors and contract proof to confirm exact color fidelity and contract compliance.

Best Practices for Effective Print Proofing

Color proof and contract proof serve distinct roles in print proofing to ensure accurate color representation and final approval. Best practices include calibrating proofing devices to match press conditions, using contract proofs with certified color standards for legal validation, and performing regular quality checks to detect discrepancies early. You can improve print accuracy and reduce costly errors by integrating both proof types strategically throughout the production process.

color proof vs contract proof Infographic

libmatt.com

libmatt.com