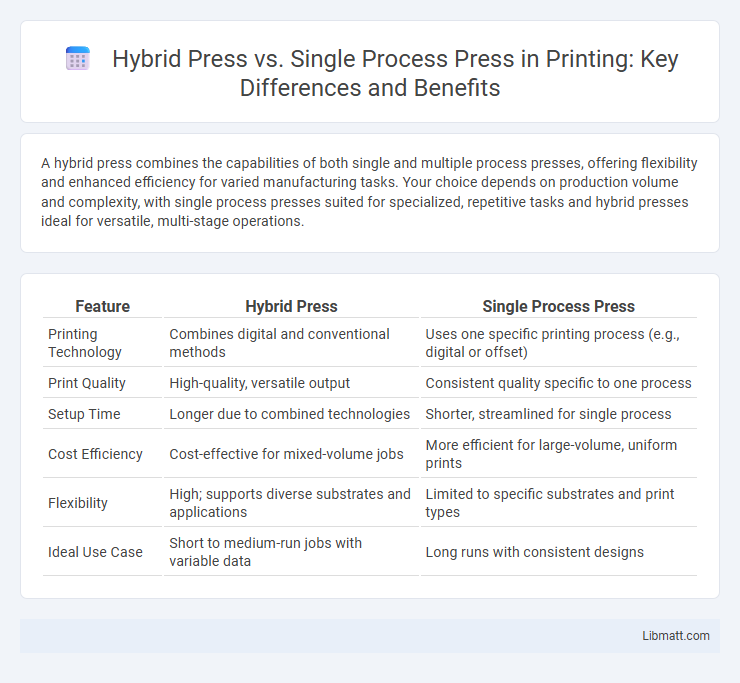

A hybrid press combines the capabilities of both single and multiple process presses, offering flexibility and enhanced efficiency for varied manufacturing tasks. Your choice depends on production volume and complexity, with single process presses suited for specialized, repetitive tasks and hybrid presses ideal for versatile, multi-stage operations.

Table of Comparison

| Feature | Hybrid Press | Single Process Press |

|---|---|---|

| Printing Technology | Combines digital and conventional methods | Uses one specific printing process (e.g., digital or offset) |

| Print Quality | High-quality, versatile output | Consistent quality specific to one process |

| Setup Time | Longer due to combined technologies | Shorter, streamlined for single process |

| Cost Efficiency | Cost-effective for mixed-volume jobs | More efficient for large-volume, uniform prints |

| Flexibility | High; supports diverse substrates and applications | Limited to specific substrates and print types |

| Ideal Use Case | Short to medium-run jobs with variable data | Long runs with consistent designs |

Understanding Hybrid Press and Single Process Press

Hybrid press technology combines the capabilities of single process and traditional offset presses, allowing for faster turnaround times and reduced waste by integrating digital and analog printing methods. Single process press relies exclusively on one printing technique, typically offset or digital, providing consistent quality but less flexibility in handling variable data or short runs. Understanding these differences highlights hybrid presses' advantage in versatility and efficiency, making them ideal for customized print jobs, while single process presses excel in high-volume, uniform output.

Key Differences Between Hybrid and Single Process Press

Hybrid press combines features of both single process and multi-process machines, enabling higher efficiency and versatility in manufacturing. Single process press focuses on one specific operation, often resulting in faster cycle times but limited flexibility. The key differences lie in operational complexity, production capacity, and adaptability to different tasks within industrial pressing applications.

Technology Overview: How Each Press Operates

Hybrid presses combine mechanical and hydraulic systems to optimize speed and precision, utilizing mechanical drive for rapid motion and hydraulic drive for controlled force during pressing cycles. Single process presses operate solely on one technology--either mechanical, relying on a flywheel for consistent, high-speed pressing, or hydraulic, using fluid pressure for adjustable force and stroke length. The hybrid press achieves enhanced flexibility and efficiency by integrating the strengths of both technologies, whereas the single process press specializes in a specific operational mode tailored to particular production requirements.

Print Quality: Hybrid Press vs Single Process Press

Hybrid presses combine digital and traditional printing techniques to deliver superior print quality with higher resolution and color accuracy compared to single process presses. Single process presses typically rely on a single technology, which may limit the range of achievable colors and detail sharpness, especially in complex or highly detailed print jobs. Hybrid systems optimize print quality by leveraging digital flexibility and traditional press consistency, resulting in more vibrant images and smoother gradients.

Flexibility and Versatility in Printing Applications

Hybrid presses combine the strengths of single process presses with additional digital capabilities, offering unmatched flexibility in handling diverse printing applications such as short runs and variable data printing. Single process presses excel in high-volume, consistent output but lack the adaptability for customized or mixed-media jobs that hybrid presses manage efficiently. This versatility enables hybrid presses to cater to a broader range of materials and print formats, making them ideal for businesses seeking dynamic production solutions.

Cost Efficiency and Operational Expenses

Hybrid presses combine the precision of single process presses with enhanced automation, significantly reducing labor costs and minimizing material waste. Single process presses typically involve higher operational expenses due to manual intervention and longer cycle times, which increase energy consumption and maintenance costs. Investing in hybrid presses leads to greater cost efficiency through faster production rates and lower overall operational expenses.

Speed and Productivity Comparison

Hybrid presses combine mechanical and hydraulic mechanisms, delivering faster cycle times than single process presses by optimizing dwell and ram speeds, which enhances overall productivity. Single process presses, while simpler, typically operate slower due to relying on one power source, limiting throughput in high-volume manufacturing environments. Hybrid technology enables quicker adjustment and higher repeatability, significantly increasing output rates compared to traditional single process presses.

Environmental Impact and Sustainability

Hybrid presses combine electric and hydraulic technologies, significantly reducing energy consumption and greenhouse gas emissions compared to single process presses, which rely solely on hydraulic power and tend to consume more energy. The improved energy efficiency of hybrid presses contributes to lower carbon footprints and supports sustainability goals by minimizing resource usage and waste generation during manufacturing processes. Single process presses often result in higher environmental impact due to their continuous high energy demands and greater wear on components, leading to increased maintenance and material replacement.

Ideal Use Cases for Each Printing Method

Hybrid presses excel in high-volume, multi-color commercial printing jobs requiring both speed and flexibility, making them ideal for catalogs, brochures, and packaging with complex color applications. Single process presses suit smaller runs or simpler jobs that demand cost efficiency and quick turnaround, such as business cards, flyers, and invitations with limited color needs. Your choice depends on print volume, color complexity, and budget constraints to achieve optimal quality and efficiency.

Choosing the Right Press for Your Business

Selecting between a hybrid press and a single process press depends on your business needs and production goals. Hybrid presses offer versatility with multiple printing techniques, ideal for businesses requiring diverse print applications and higher efficiency. Single process presses provide specialized, cost-effective solutions for focused production runs with consistent quality and simplicity.

Hybrid press vs single process press Infographic

libmatt.com

libmatt.com