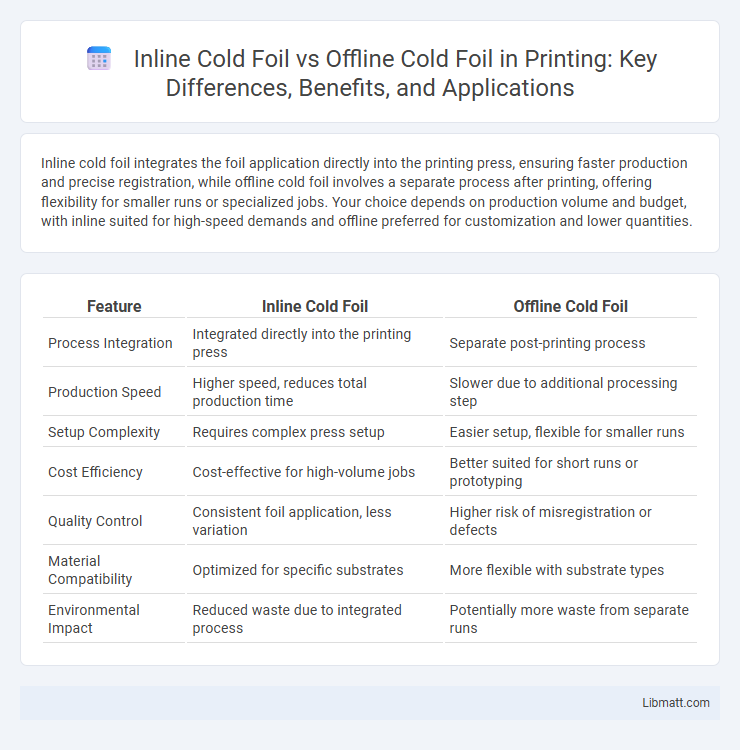

Inline cold foil integrates the foil application directly into the printing press, ensuring faster production and precise registration, while offline cold foil involves a separate process after printing, offering flexibility for smaller runs or specialized jobs. Your choice depends on production volume and budget, with inline suited for high-speed demands and offline preferred for customization and lower quantities.

Table of Comparison

| Feature | Inline Cold Foil | Offline Cold Foil |

|---|---|---|

| Process Integration | Integrated directly into the printing press | Separate post-printing process |

| Production Speed | Higher speed, reduces total production time | Slower due to additional processing step |

| Setup Complexity | Requires complex press setup | Easier setup, flexible for smaller runs |

| Cost Efficiency | Cost-effective for high-volume jobs | Better suited for short runs or prototyping |

| Quality Control | Consistent foil application, less variation | Higher risk of misregistration or defects |

| Material Compatibility | Optimized for specific substrates | More flexible with substrate types |

| Environmental Impact | Reduced waste due to integrated process | Potentially more waste from separate runs |

Introduction to Cold Foil Technology

Cold foil technology enhances packaging aesthetics by applying a metallic foil using UV-curable adhesive, creating high-impact visual effects. Inline cold foil systems integrate directly with the printing press, enabling simultaneous application and reducing production time, while offline cold foil involves a separate process after printing, offering greater flexibility but longer turnaround. Choosing between inline and offline cold foil depends on production volume, cost-efficiency, and specific design requirements.

Overview: Inline Cold Foil vs Offline Cold Foil

Inline cold foil integrates directly into the printing press, enabling simultaneous printing and foil application, which increases production speed and reduces handling. Offline cold foil is a separate process where foil is applied after printing, offering greater flexibility in foil placement and variety but adding extra production steps. Choosing between inline and offline cold foil depends on project complexity, production volume, and desired finish quality.

How Inline Cold Foil Works

Inline cold foil printing integrates foil application directly within the printing press, allowing simultaneous foil transfer during the printing process. This technique uses an ultraviolet (UV) adhesive cured immediately after the foil is pressed onto the substrate, ensuring precise registration and high production efficiency. Inline cold foil significantly reduces setup time and waste compared to offline cold foil, where foil application occurs in a separate step after printing.

How Offline Cold Foil Works

Offline cold foil involves printing a metallic adhesive pattern on the substrate using a flexographic or digital press, then laminating a cold foil on top using a separate lamination unit. The foil adheres only to the printed adhesive areas, creating precise metallic finishes without the need for heat. This process allows high-quality, cost-effective decorative effects on various packaging materials.

Key Differences Between Inline and Offline Cold Foil

Inline cold foil integrates the foiling process directly into the printing press, allowing simultaneous printing and foiling, which reduces production time and improves registration accuracy. Offline cold foil requires a separate foiling step after printing, offering greater flexibility for shorter runs and varied substrates but increasing production time and handling. Inline systems often provide higher efficiency for large volumes, whereas offline setups excel in customization and adaptability to different foil types and applications.

Advantages of Inline Cold Foil

Inline cold foil offers superior production efficiency by integrating foil application directly into the printing process, reducing setup times and minimizing waste. This method ensures precise registration and consistent quality, enhancing overall print accuracy and durability. You benefit from faster turnaround times and cost savings, making inline cold foil ideal for high-volume packaging and labeling projects.

Benefits of Offline Cold Foil

Offline cold foil offers enhanced flexibility by allowing you to apply foil on a broader range of substrates and print runs, including shorter batches. This method often results in higher-quality foil application with less risk of damaging the printing plates, preserving your original artwork. Cost efficiency is another key benefit, as offline cold foil can reduce machine setup time and decrease material wastage compared to inline systems.

Factors to Consider When Choosing Cold Foil Methods

Choosing between inline cold foil and offline cold foil involves evaluating production speed, print quality, and cost efficiency. Inline cold foil integrates foiling directly within the printing press, offering faster turnaround and better registration accuracy, ideal for high-volume runs. Offline cold foil, applied in a separate process, provides more flexibility in substrate choice and design complexity, but may increase handling time and overall production costs.

Cost Implications of Inline vs Offline Cold Foil

Inline cold foil typically reduces overall production costs by integrating foil application directly into the printing press, eliminating additional handling and setup expenses associated with offline processes. Offline cold foil requires separate equipment and additional labor, increasing operational costs and production time. Businesses can optimize Your budget by choosing inline cold foil for high-volume runs where cost efficiency is critical.

Applications and Industry Use Cases

Inline cold foil technology integrates foil application directly into the printing press, making it ideal for high-speed production of flexible packaging, labels, and folding cartons in industries such as cosmetics, food and beverage, and pharmaceuticals. Offline cold foil processes, performed separately from printing, offer greater flexibility for short runs and specialty applications like premium packaging and promotional materials in sectors including luxury goods and consumer electronics. Both methods enhance visual appeal and brand differentiation but serve distinct market needs based on production volume and customization requirements.

Inline cold foil vs offline cold foil Infographic

libmatt.com

libmatt.com