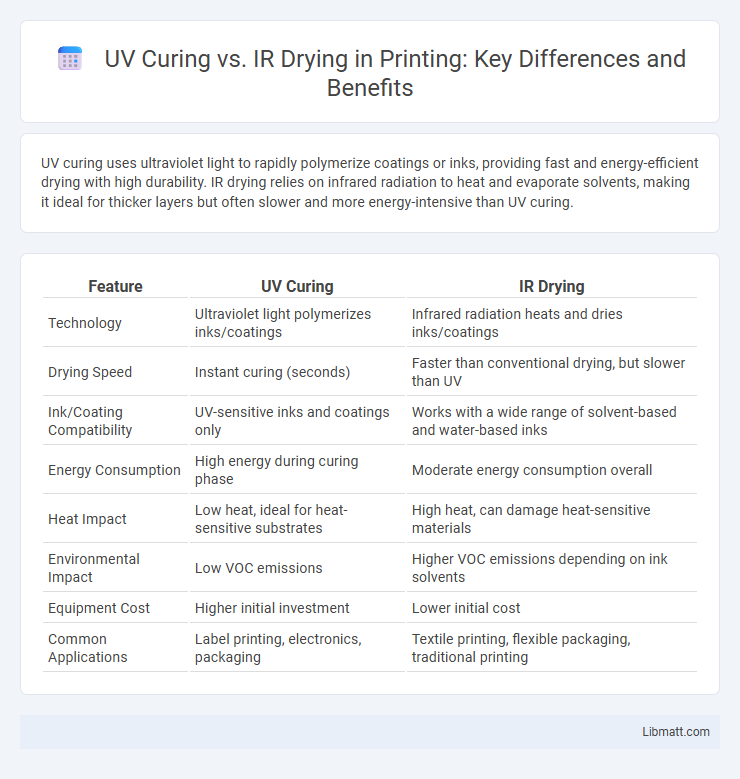

UV curing uses ultraviolet light to rapidly polymerize coatings or inks, providing fast and energy-efficient drying with high durability. IR drying relies on infrared radiation to heat and evaporate solvents, making it ideal for thicker layers but often slower and more energy-intensive than UV curing.

Table of Comparison

| Feature | UV Curing | IR Drying |

|---|---|---|

| Technology | Ultraviolet light polymerizes inks/coatings | Infrared radiation heats and dries inks/coatings |

| Drying Speed | Instant curing (seconds) | Faster than conventional drying, but slower than UV |

| Ink/Coating Compatibility | UV-sensitive inks and coatings only | Works with a wide range of solvent-based and water-based inks |

| Energy Consumption | High energy during curing phase | Moderate energy consumption overall |

| Heat Impact | Low heat, ideal for heat-sensitive substrates | High heat, can damage heat-sensitive materials |

| Environmental Impact | Low VOC emissions | Higher VOC emissions depending on ink solvents |

| Equipment Cost | Higher initial investment | Lower initial cost |

| Common Applications | Label printing, electronics, packaging | Textile printing, flexible packaging, traditional printing |

Introduction to UV Curing and IR Drying

UV curing employs ultraviolet light to rapidly harden or cure coatings, inks, and adhesives by triggering a photochemical reaction, resulting in instant polymerization. IR drying uses infrared radiation to transfer heat directly to the material, evaporating solvents and moisture, making it effective for drying thick layers or heat-sensitive substrates. Both technologies offer distinct advantages in manufacturing processes, with UV curing emphasizing speed and energy efficiency, while IR drying provides gentle, uniform heating.

How UV Curing Works: Principles and Process

UV curing uses ultraviolet light to initiate a photochemical reaction that rapidly hardens or cures coatings, inks, or adhesives. This process involves exposing the material to UV rays, which activate photoinitiators, leading to polymerization and cross-linking at a molecular level. Your production line benefits from this efficient, instant curing method, ensuring faster processing times and improved product durability compared to conventional IR drying.

Understanding IR Drying: Mechanism and Applications

Infrared (IR) drying utilizes electromagnetic radiation between 0.7 to 1,000 microns to generate heat by exciting molecules in coatings, inks, or adhesives, resulting in rapid moisture evaporation or solvent removal. This mechanism enables uniform drying with minimal substrate heating, making IR drying ideal for heat-sensitive materials in industries such as printing, automotive, and electronics. Your choice of IR drying can enhance production speed and energy efficiency in processes requiring precise temperature control and surface curing.

Key Applications of UV Curing in Industry

UV curing technology is extensively used in the electronics manufacturing industry for rapid curing of coatings and adhesives, ensuring high precision and durability in circuit boards. In the automotive sector, UV curing enables fast drying of paints and coatings, enhancing production efficiency and surface hardness. Additionally, UV curing is vital in the printing industry for quick-drying inks, which improves print quality and reduces production time.

Common Uses of IR Drying in Manufacturing

IR drying is widely used in manufacturing processes such as paint curing, ink drying, and moisture removal from coated surfaces. Its ability to rapidly heat materials without direct contact makes it ideal for drying adhesives, coatings, and printed electronics. Common industries utilizing IR drying include automotive, packaging, and textiles, where speed and energy efficiency are critical.

Advantages of UV Curing Technology

UV curing technology offers rapid drying times, often within seconds, significantly boosting production efficiency compared to IR drying methods. It provides superior energy efficiency by converting light directly into chemical energy, reducing operational costs and environmental impact. Your manufacturing process benefits from enhanced coating durability and chemical resistance, ensuring higher quality finishes with minimal heat exposure to substrates.

Benefits and Limitations of IR Drying

IR drying offers efficient heat transfer through infrared radiation, enabling rapid drying times and reduced energy consumption compared to traditional methods. Its ability to penetrate substrates makes it ideal for thick or multilayer coatings, but limitations include uneven drying on complex shapes and potential heat damage to heat-sensitive materials. You should consider substrate type and product design when choosing IR drying to maximize efficiency and product quality.

UV Curing vs IR Drying: Efficiency and Speed Comparison

UV curing offers superior efficiency and faster processing times compared to IR drying, as it instantly polymerizes coatings and adhesives using ultraviolet light. IR drying relies on heat transfer to evaporate solvents, which generally requires longer cycle times and greater energy consumption. Your production line benefits from UV curing's rapid cure times, reducing overall downtime and increasing throughput.

Environmental and Safety Considerations

UV curing utilizes ultraviolet light to rapidly polymerize coatings, drastically reducing volatile organic compound (VOC) emissions compared to traditional drying methods, thereby minimizing environmental impact. IR drying emits radiant heat, which can lead to higher energy consumption and potential emission of heat-sensitive volatile compounds, increasing environmental concerns. UV curing systems typically incorporate safety features such as shielding and interlocks to protect operators from harmful UV exposure, while IR drying requires caution to prevent burns and overheating hazards, emphasizing the need for proper ventilation and protective equipment.

Choosing Between UV Curing and IR Drying: Factors to Consider

Selecting between UV curing and IR drying hinges on factors such as substrate compatibility, curing speed, and energy efficiency. UV curing offers rapid polymerization and is ideal for coatings and inks sensitive to heat, whereas IR drying excels with heat-tolerant materials requiring deeper moisture removal. Consider production line speed, environmental impact, and final product performance to determine the optimal curing or drying method.

UV Curing vs IR Drying Infographic

libmatt.com

libmatt.com