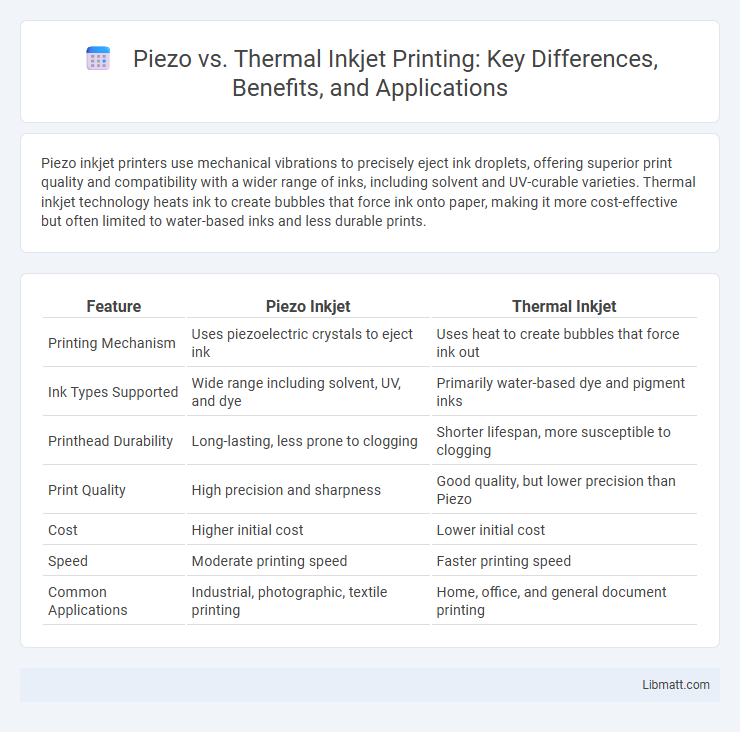

Piezo inkjet printers use mechanical vibrations to precisely eject ink droplets, offering superior print quality and compatibility with a wider range of inks, including solvent and UV-curable varieties. Thermal inkjet technology heats ink to create bubbles that force ink onto paper, making it more cost-effective but often limited to water-based inks and less durable prints.

Table of Comparison

| Feature | Piezo Inkjet | Thermal Inkjet |

|---|---|---|

| Printing Mechanism | Uses piezoelectric crystals to eject ink | Uses heat to create bubbles that force ink out |

| Ink Types Supported | Wide range including solvent, UV, and dye | Primarily water-based dye and pigment inks |

| Printhead Durability | Long-lasting, less prone to clogging | Shorter lifespan, more susceptible to clogging |

| Print Quality | High precision and sharpness | Good quality, but lower precision than Piezo |

| Cost | Higher initial cost | Lower initial cost |

| Speed | Moderate printing speed | Faster printing speed |

| Common Applications | Industrial, photographic, textile printing | Home, office, and general document printing |

Introduction to Inkjet Printing Technologies

Piezo and thermal inkjet technologies represent two primary methods for generating ink droplets in inkjet printing, each utilizing distinct mechanisms. Piezo inkjet printers employ a piezoelectric crystal to create precise pressure pulses, enabling finer control over droplet size and ink variety. Thermal inkjet printers use rapid heating to vaporize ink and form droplets, offering affordability and simplicity but with limited ink compatibility compared to piezo technology, which can affect your printing needs based on application requirements.

What is Piezo Inkjet Printing?

Piezo inkjet printing utilizes piezoelectric crystals that contract and expand when an electric current passes through them, precisely controlling ink droplet ejection without heat. This method allows for a wide range of ink types, including solvent, UV-curable, and water-based inks, offering superior durability and color vibrancy compared to thermal inkjet technology. Your choice of piezo inkjet printing can ensure higher print quality and longer printhead lifespan, especially for industrial and high-volume applications.

What is Thermal Inkjet Printing?

Thermal inkjet printing uses tiny resistors to heat ink, creating bubbles that push droplets onto the paper with high precision and speed. This method excels in producing vibrant colors and fine details, making it ideal for photo printing and general office use. Your choice between piezo and thermal inkjet depends on factors like print quality, ink compatibility, and cost efficiency.

Key Differences Between Piezo and Thermal Inkjet

Piezo inkjet printers use piezoelectric crystals to generate precise mechanical pressure, allowing for a wider range of ink types and higher durability. Thermal inkjet printers rely on heating elements to vaporize ink, which limits ink compatibility but offers simpler and cost-effective design. The key differences include ink formulation flexibility, printhead longevity, and variations in droplet size control, impacting print quality and maintenance requirements.

Print Quality Comparison: Piezo vs Thermal

Piezo inkjet printers deliver superior print quality by precisely controlling droplet size and placement, resulting in sharper images and smoother gradients. Thermal inkjet technology heats ink to create bubbles, often producing slightly less consistent droplet sizes, which can affect fine detail reproduction. When print quality is paramount for your projects, Piezo technology offers enhanced color accuracy and durability.

Ink Types Compatible with Piezo and Thermal

Piezo printheads support a wider range of ink types, including solvent, UV-curable, and dye-based inks, making them highly versatile for different applications. Thermal inkjet technology is primarily compatible with water-based inks due to its heating mechanism, which limits its use with heat-sensitive materials. Understanding these compatibility differences can help you choose the ideal printing method for your specific ink requirements.

Printhead Durability and Maintenance

Piezo printheads offer superior durability compared to thermal inkjet printheads, as they use mechanical piezoelectric crystals instead of heat to eject ink, reducing wear and extending the printhead's lifespan. Maintenance requirements for Piezo technology are generally lower due to less clogging and ink residue buildup, which means fewer interruptions and longer print runs. Your choice between Piezo and thermal inkjet affects overall operational efficiency, especially in high-volume or industrial printing environments.

Cost Considerations: Piezo vs Thermal

Piezo inkjet printers usually have higher upfront costs due to their advanced piezoelectric technology and durable components, but they offer lower long-term maintenance expenses by using a wider range of inks without damage. Thermal inkjet printers tend to be more affordable initially, making them ideal for budget-conscious users, yet they often incur higher operating costs because their printheads wear out faster and require frequent replacement. Your choice between Piezo and Thermal inkjet printing should weigh initial investment against ongoing costs based on printing volume and ink compatibility.

Ideal Applications for Piezo and Thermal Inkjet

Piezo inkjet technology excels in industrial applications requiring precise control of droplet size and variable ink viscosities, making it ideal for printing on diverse surfaces like textiles, ceramics, and electronics. Thermal inkjet printers are best suited for high-speed document printing and photo-quality color images on standard office papers, leveraging rapid heating elements to eject ink consistently. Your choice depends on whether you prioritize durability and material versatility with Piezo or cost-effectiveness and speed with Thermal Inkjet.

Choosing the Right Inkjet Technology

Piezo inkjet technology offers precise control over droplet size and can handle a wider range of inks, making it ideal for industrial and high-quality printing applications. Thermal inkjet technology relies on rapid heating to create ink droplets, providing faster print speeds and lower initial costs, suitable for consumer and general office use. Selecting the right inkjet technology depends on factors like print quality requirements, ink compatibility, production speed, and budget constraints.

Piezo vs Thermal Inkjet Infographic

libmatt.com

libmatt.com