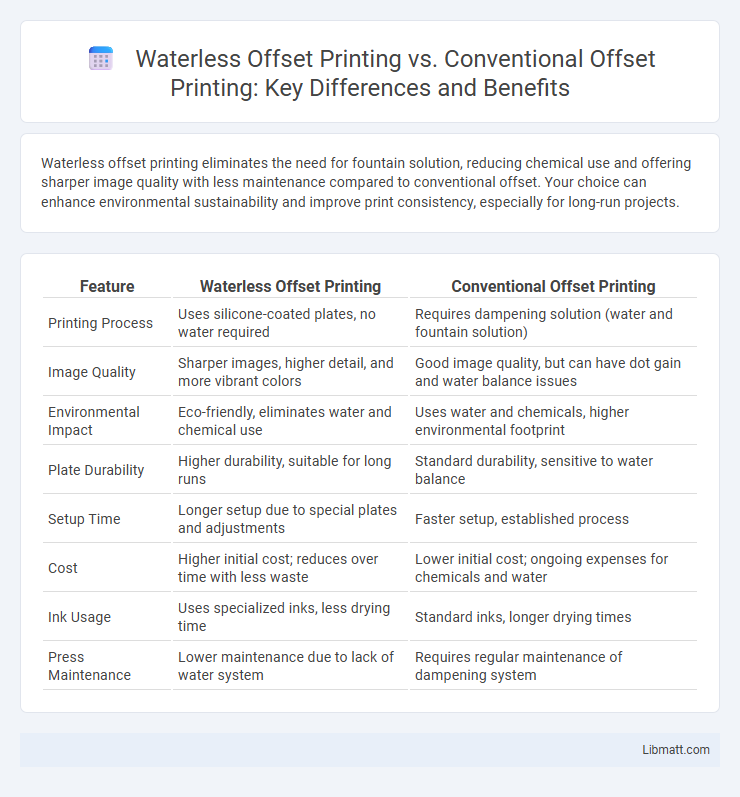

Waterless offset printing eliminates the need for fountain solution, reducing chemical use and offering sharper image quality with less maintenance compared to conventional offset. Your choice can enhance environmental sustainability and improve print consistency, especially for long-run projects.

Table of Comparison

| Feature | Waterless Offset Printing | Conventional Offset Printing |

|---|---|---|

| Printing Process | Uses silicone-coated plates, no water required | Requires dampening solution (water and fountain solution) |

| Image Quality | Sharper images, higher detail, and more vibrant colors | Good image quality, but can have dot gain and water balance issues |

| Environmental Impact | Eco-friendly, eliminates water and chemical use | Uses water and chemicals, higher environmental footprint |

| Plate Durability | Higher durability, suitable for long runs | Standard durability, sensitive to water balance |

| Setup Time | Longer setup due to special plates and adjustments | Faster setup, established process |

| Cost | Higher initial cost; reduces over time with less waste | Lower initial cost; ongoing expenses for chemicals and water |

| Ink Usage | Uses specialized inks, less drying time | Standard inks, longer drying times |

| Press Maintenance | Lower maintenance due to lack of water system | Requires regular maintenance of dampening system |

Introduction to Offset Printing Technologies

Waterless offset printing employs a silicone coating instead of water to repel ink from non-image areas, resulting in sharper images and faster setup times compared to conventional offset printing. Conventional offset relies on the balance of water and ink to transfer images from plate to blanket, which can lead to variations in print quality due to moisture management challenges. Understanding these key differences helps optimize your printing process for improved efficiency and image precision.

Defining Waterless and Conventional Offset Printing

Waterless offset printing uses a silicone rubber plate that repels ink in non-image areas without the need for water or dampening solutions, enabling higher image quality and reduced environmental impact. Conventional offset printing relies on a dampening system where water and ink are applied to the plate, maintaining balance to prevent ink from adhering to non-image areas. Understanding the fundamental differences between waterless and conventional offset printing helps you choose the best method for precise, efficient production tailored to your printing needs.

Key Differences in Printing Processes

Waterless offset printing eliminates the need for dampening solutions by using specially coated plates and silicone-based blankets, resulting in sharper images and reduced water-related issues. Conventional offset printing relies on a water-based fountain solution to balance ink and water on the plate, which can lead to challenges such as ink-water balance and longer setup times. Your choice between these processes impacts print quality, environmental considerations, and operational efficiency.

Advantages of Waterless Offset Printing

Waterless offset printing offers superior image quality and sharper detail due to the absence of water, which eliminates ink-water balance issues found in conventional offset. It reduces environmental impact by eliminating water consumption and chemical processing, resulting in less waste and fewer emissions. Faster setup times and reduced maintenance costs enhance production efficiency and overall profitability in print operations.

Advantages of Conventional Offset Printing

Conventional offset printing offers superior color accuracy and consistency, making it ideal for high-volume runs with precise image reproduction. Its well-established technology supports a wide range of paper types and surface finishes, providing flexibility for diverse printing needs. You benefit from lower unit costs for large quantities, as conventional offset plates are cheaper to produce compared to waterless alternatives.

Print Quality Comparison

Waterless offset printing delivers superior print quality with sharper images, more vibrant colors, and finer details due to its precise ink control and absence of water, which eliminates issues like ink-water balance problems and dot gain common in conventional offset. Conventional offset printing often experiences variations in print consistency and color fidelity because of water-based emulsions affecting ink adhesion and drying times. The waterless process generates higher resolution prints, making it ideal for projects demanding exceptional detail and color accuracy.

Environmental Impact and Sustainability

Waterless offset printing significantly reduces water consumption and eliminates the use of fountain solutions containing harmful chemicals, minimizing wastewater pollution compared to conventional offset processes. Conventional offset printing relies heavily on water and chemical additives, which contribute to higher environmental waste and energy use, increasing its carbon footprint. The sustainable advantages of waterless offset include lower energy requirements and reduced toxic emissions, aligning better with eco-friendly production practices.

Cost Implications and Considerations

Waterless offset printing reduces costs by eliminating the need for dampening solutions and their associated maintenance, lowering chemical and water expenses. Conventional offset may have higher operational costs due to frequent water and fountain solution replacements, increased machine downtime, and environmental disposal compliance. Your choice between waterless and conventional offset should factor in initial equipment investment, ongoing material costs, and potential savings from improved print consistency and reduced waste.

Ideal Applications for Each Offset Method

Waterless offset printing excels in high-quality image reproduction and fine detail, making it ideal for packaging, labels, and premium marketing materials where color consistency and environmental benefits are crucial. Conventional offset printing suits large-volume runs such as newspapers, magazines, and brochures due to its cost-effectiveness and adaptability to various paper types. Choosing between the two depends on factors like print run size, image quality requirements, and sustainability goals.

Choosing the Best Offset Method for Your Project

Waterless offset printing offers superior image quality and environmental benefits due to the absence of water, making it ideal for detailed, high-volume projects with consistent print runs. Conventional offset printing provides greater flexibility and cost-effectiveness for a wide range of substrates and short-run projects that require frequent plate changes. Evaluating your project's volume, substrate type, and quality requirements will help determine whether waterless or conventional offset meets your printing needs most effectively.

Waterless Offset vs Conventional Offset Infographic

libmatt.com

libmatt.com