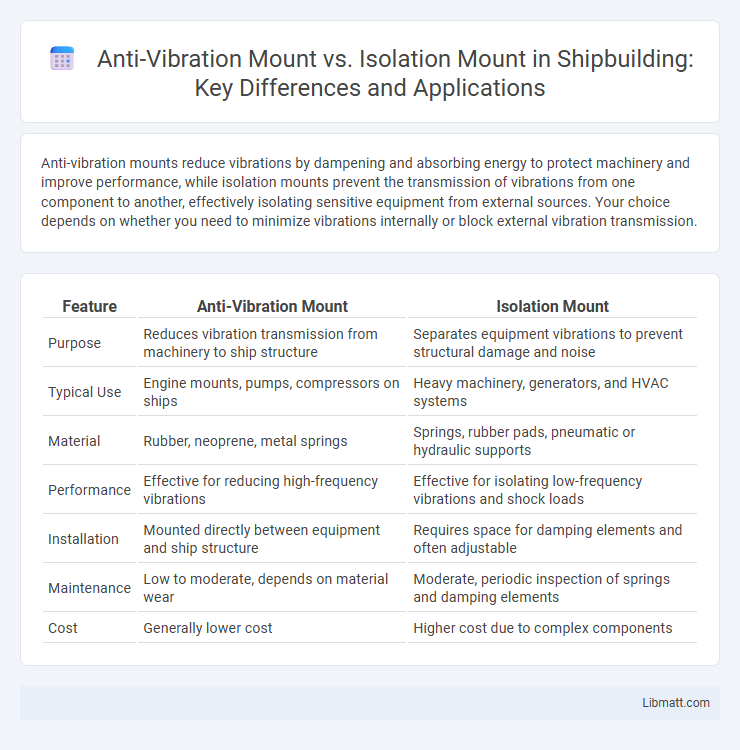

Anti-vibration mounts reduce vibrations by dampening and absorbing energy to protect machinery and improve performance, while isolation mounts prevent the transmission of vibrations from one component to another, effectively isolating sensitive equipment from external sources. Your choice depends on whether you need to minimize vibrations internally or block external vibration transmission.

Table of Comparison

| Feature | Anti-Vibration Mount | Isolation Mount |

|---|---|---|

| Purpose | Reduces vibration transmission from machinery to ship structure | Separates equipment vibrations to prevent structural damage and noise |

| Typical Use | Engine mounts, pumps, compressors on ships | Heavy machinery, generators, and HVAC systems |

| Material | Rubber, neoprene, metal springs | Springs, rubber pads, pneumatic or hydraulic supports |

| Performance | Effective for reducing high-frequency vibrations | Effective for isolating low-frequency vibrations and shock loads |

| Installation | Mounted directly between equipment and ship structure | Requires space for damping elements and often adjustable |

| Maintenance | Low to moderate, depends on material wear | Moderate, periodic inspection of springs and damping elements |

| Cost | Generally lower cost | Higher cost due to complex components |

Introduction to Anti-Vibration Mounts and Isolation Mounts

Anti-vibration mounts reduce vibration transmission by absorbing and dampening mechanical energy, protecting equipment and enhancing longevity. Isolation mounts focus on isolating vibrations by creating a flexible barrier between the source and the structure, minimizing noise and structural damage. Your choice depends on the specific application requirements for vibration control and environmental conditions.

What Are Anti-Vibration Mounts?

Anti-vibration mounts are designed to reduce the transmission of vibrations between machinery and its supporting structure, improving equipment performance and longevity. These mounts typically use elastomeric materials to absorb and dissipate vibrational energy, minimizing noise and structural damage. Isolation mounts differ by primarily focusing on isolating equipment from shock and impact forces rather than continuous vibrations.

What Are Isolation Mounts?

Isolation mounts are specialized components designed to reduce the transmission of vibration and noise between machinery and its supporting structure by creating a flexible barrier. These mounts typically feature materials like rubber or elastomers that absorb and dissipate energy, enhancing equipment longevity and operator comfort. Isolation mounts differ from anti-vibration mounts by focusing primarily on minimizing structural vibrations rather than solely dampening vibrations at the source.

Key Differences Between Anti-Vibration and Isolation Mounts

Anti-vibration mounts primarily reduce vibration by absorbing and damping high-frequency oscillations, while isolation mounts focus on minimizing the transmission of low-frequency vibrations and shock between surfaces. The key differences lie in their design and material composition, with anti-vibration mounts often made from rubber or elastomers for flexibility, and isolation mounts using springs or pneumatic components to achieve superior isolation. Selecting the right mount for your equipment depends on the specific vibration frequencies and environmental conditions you need to control.

How Each Mount Works: Mechanisms and Principles

Anti-vibration mounts function by absorbing and dissipating energy from mechanical vibrations through materials like rubber or elastomers, which deform to reduce transmitted forces. Isolation mounts operate by decoupling equipment from vibration sources using springs or air cushions, creating a physical barrier that limits vibration transfer. Understanding these mechanisms helps you select the right mount to protect your machinery and improve operational stability.

Pros and Cons of Anti-Vibration Mounts

Anti-vibration mounts excel in reducing noise and absorbing shock in machinery, enhancing equipment longevity and operator comfort, but they may have limited effectiveness against low-frequency vibrations compared to isolation mounts. Your choice depends on specific application requirements, as anti-vibration mounts are generally easier to install and maintain but can wear out faster under heavy dynamic loads. These mounts provide cost-effective damping solutions yet may not isolate vibrations as completely as more advanced isolation mounts designed for precise environmental control.

Pros and Cons of Isolation Mounts

Isolation mounts offer superior vibration reduction by effectively decoupling equipment from surrounding structures, which minimizes noise and extends machinery lifespan. However, they can be more expensive and complex to install compared to anti-vibration mounts, requiring precise adjustment to achieve optimal performance. Your choice of isolation mounts should consider these trade-offs to ensure maximum protection and cost-efficiency.

Applications of Anti-Vibration Mounts

Anti-vibration mounts are widely used in industrial machinery, HVAC equipment, and automotive engines to reduce noise and prevent damage from vibration-induced stress. These mounts effectively absorb and dampen vibrations, enhancing equipment longevity and operator comfort in manufacturing plants, construction sites, and transportation systems. In contrast, isolation mounts are typically employed in sensitive electronic devices and precision instruments requiring minimal movement and maximum vibration isolation.

Applications of Isolation Mounts

Isolation mounts are primarily used in industries requiring vibration control to protect sensitive equipment such as precision instruments, medical devices, and electronic components. These mounts effectively reduce transmitted vibrations in HVAC systems, industrial machinery, and automotive applications, enhancing operational longevity and performance. Understanding the specific application of your machinery helps determine the ideal isolation mount to ensure optimal vibration isolation and noise reduction.

Choosing the Right Mount: Anti-Vibration vs Isolation

Anti-vibration mounts are designed to reduce the transmission of vibrations from machinery to surrounding structures by absorbing and dampening vibrational energy, making them ideal for equipment with consistent operational frequencies. Isolation mounts provide broader protection by decoupling the equipment from external vibrations and shock, suitable for environments with varying or impact-based disturbances. Selecting the right mount depends on the specific vibration profile, load characteristics, and environmental conditions to optimize machinery performance and longevity.

Anti-vibration mount vs isolation mount Infographic

libmatt.com

libmatt.com