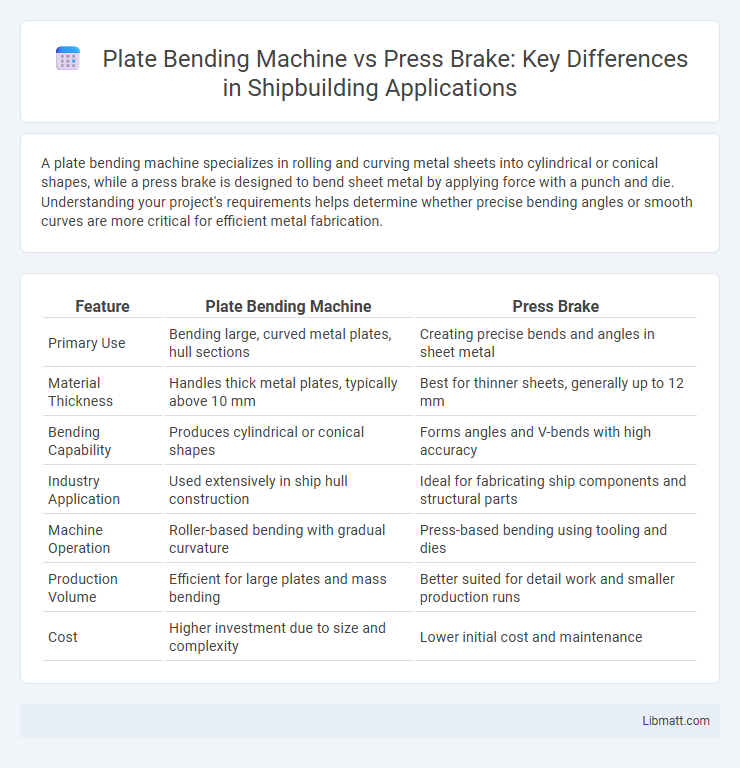

A plate bending machine specializes in rolling and curving metal sheets into cylindrical or conical shapes, while a press brake is designed to bend sheet metal by applying force with a punch and die. Understanding your project's requirements helps determine whether precise bending angles or smooth curves are more critical for efficient metal fabrication.

Table of Comparison

| Feature | Plate Bending Machine | Press Brake |

|---|---|---|

| Primary Use | Bending large, curved metal plates, hull sections | Creating precise bends and angles in sheet metal |

| Material Thickness | Handles thick metal plates, typically above 10 mm | Best for thinner sheets, generally up to 12 mm |

| Bending Capability | Produces cylindrical or conical shapes | Forms angles and V-bends with high accuracy |

| Industry Application | Used extensively in ship hull construction | Ideal for fabricating ship components and structural parts |

| Machine Operation | Roller-based bending with gradual curvature | Press-based bending using tooling and dies |

| Production Volume | Efficient for large plates and mass bending | Better suited for detail work and smaller production runs |

| Cost | Higher investment due to size and complexity | Lower initial cost and maintenance |

Overview of Plate Bending Machines and Press Brakes

Plate bending machines are specialized tools designed to bend and shape metal plates into curved or cylindrical forms with precision and efficiency. Press brakes use a punch and die mechanism to create precise bends and folds in sheet metal, allowing for angular or complex shapes. Both machines serve distinct purposes in metal fabrication, with plate bending machines excelling in curved profiles and press brakes providing versatility for a wide range of bend angles and shapes.

Key Functions and Applications

Plate bending machines primarily perform precise curvature and cylindrical shaping of metal sheets, making them ideal for creating pipes, tanks, and curved structural components. Press brakes excel at bending sheet metal into angular forms, producing components such as brackets, enclosures, and frames with high accuracy in straight bends. Both machines serve distinct roles in metal fabrication, with plate bending machines focusing on rolling and forming curves, while press brakes specialize in angular bending for varied sheet metal applications.

Working Principles Compared

Plate bending machines use a system of rollers that apply continuous pressure to gradually curve metal sheets, enabling smooth and precise cylindrical or conical shapes. Press brakes operate by clamping the sheet between a punch and a die, using high force to create bends with defined angles and sharp edges. The key difference lies in the bending process: plate bending relies on incremental rolling deformation, while press brakes use direct mechanical or hydraulic pressing for angular bends.

Material Compatibility

Plate bending machines excel at handling thick, heavy metals like steel and aluminum, offering precise curvature for large or complex shapes. Press brakes are more versatile with a wide range of materials, from thin sheets to moderately thick plates, enabling sharp bends and detailed bends in steel, stainless steel, and non-ferrous metals. Your choice depends on the material thickness and shape precision required for your project.

Precision and Accuracy Features

Press brakes offer superior precision and accuracy for bending complex sheet metal shapes due to advanced CNC controls and programmable backgauges. Plate bending machines provide consistent radius bends on thicker metal plates but generally lack the fine control needed for intricate designs. Your choice depends on whether high-precision angular bends or smooth, curved plate deformation is required.

Production Speed and Efficiency

Plate bending machines provide higher production speed and efficiency by automating the bending process with precision-controlled rollers, making them ideal for large-scale industrial applications. Press brakes, while versatile and capable of producing complex bends with high accuracy, typically operate at slower speeds due to manual setup and incremental bending strokes. For mass production environments requiring rapid throughput, plate bending machines outperform press brakes in overall efficiency and cycle time reduction.

Flexibility in Forming Operations

Plate bending machines offer greater flexibility in forming complex curved shapes due to their ability to roll various radius bends along the length of the metal sheet. Press brakes excel in precision bending at specific angles, making them ideal for creating sharp folds, V-bends, and U-bends with consistent repeatability. While plate bending machines are preferred for cylindrical, conical, and irregular forms, press brakes are optimized for versatile angular bending tasks and intricate profile shapes.

Maintenance and Operational Costs

Plate bending machines typically require less frequent maintenance due to fewer moving parts and simpler hydraulic systems, resulting in lower operational costs over time. Press brakes involve complex tooling and tighter tolerances, which often lead to higher maintenance demands and increased expenses for part replacements and calibration. Choosing between the two depends on the balance between initial investment and long-term maintenance efficiency.

Industry-Specific Use Cases

Plate bending machines excel in industries requiring precise, curved metal components such as shipbuilding, aerospace, and heavy machinery manufacturing due to their ability to form cylindrical and conical shapes. Press brakes are preferred in automotive and appliance industries for creating complex bends and folds in sheet metal, enabling the fabrication of parts like chassis frames and enclosures. Both tools cater to distinct industrial needs, with plate bending machines offering specialized applications for round and cylindrical designs, while press brakes deliver versatility for angular and straight bends.

Choosing the Right Machine for Your Needs

Selecting the right machine depends on the specific metal forming tasks you need to accomplish. A plate bending machine excels at creating smooth, curved bends in sheet metal, making it ideal for cylindrical or conical shapes, while a press brake offers precise, angular bends suitable for complex, multi-angle parts. Consider your production volume, bend accuracy requirements, and the types of bends you frequently perform to determine whether a plate bending machine or press brake best fits your manufacturing needs.

Plate bending machine vs press brake Infographic

libmatt.com

libmatt.com