Azimuth thrusters provide 360-degree rotational thrust, offering superior maneuverability and precise vessel control compared to tunnel thrusters, which are fixed in tunnels and typically provide lateral thrust for docking and slow-speed operations. Your choice depends on operational needs, with azimuth thrusters favored for dynamic positioning and turning, while tunnel thrusters are cost-effective solutions for side thrust during low-speed maneuvers.

Table of Comparison

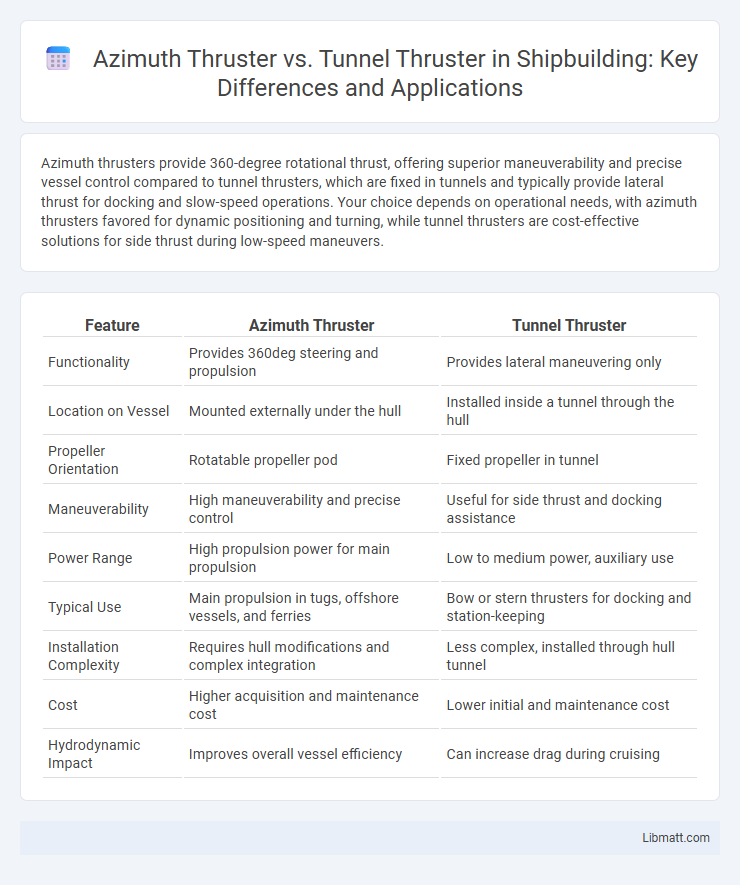

| Feature | Azimuth Thruster | Tunnel Thruster |

|---|---|---|

| Functionality | Provides 360deg steering and propulsion | Provides lateral maneuvering only |

| Location on Vessel | Mounted externally under the hull | Installed inside a tunnel through the hull |

| Propeller Orientation | Rotatable propeller pod | Fixed propeller in tunnel |

| Maneuverability | High maneuverability and precise control | Useful for side thrust and docking assistance |

| Power Range | High propulsion power for main propulsion | Low to medium power, auxiliary use |

| Typical Use | Main propulsion in tugs, offshore vessels, and ferries | Bow or stern thrusters for docking and station-keeping |

| Installation Complexity | Requires hull modifications and complex integration | Less complex, installed through hull tunnel |

| Cost | Higher acquisition and maintenance cost | Lower initial and maintenance cost |

| Hydrodynamic Impact | Improves overall vessel efficiency | Can increase drag during cruising |

Introduction to Azimuth and Tunnel Thrusters

Azimuth thrusters provide 360-degree rotational propulsion, allowing vessels to achieve exceptional maneuverability and precise positioning, especially useful in dynamic marine environments. Tunnel thrusters, typically installed transversely within a ship's hull near the bow or stern, generate lateral thrust to assist with docking and low-speed maneuvering. Both systems enhance vessel handling but differ in design and operational flexibility, with azimuth thrusters offering full directional control and tunnel thrusters providing sideways thrust without changing vessel heading.

How Azimuth Thrusters Work

Azimuth thrusters operate by rotating 360 degrees around a vertical axis, allowing vessels to achieve exceptional maneuverability and precise directional control. They generate thrust by using a propeller mounted on a pod that can swivel, enabling efficient propulsion and steering without the need for a traditional rudder. Your vessel benefits from enhanced agility, making dockside maneuvers and complex navigation significantly easier compared to tunnel thrusters.

How Tunnel Thrusters Function

Tunnel thrusters function by using a duct-mounted propeller installed transversely in the hull of a vessel, creating lateral thrust to assist with maneuvering at low speeds or during docking. Unlike azimuth thrusters, which rotate 360 degrees for propulsion and steering, tunnel thrusters provide sideways control without altering the vessel's forward drive. Your ship benefits from improved maneuverability in tight spaces due to the efficient side thrust generated by these tunnel-mounted units.

Key Differences Between Azimuth and Tunnel Thrusters

Azimuth thrusters provide 360-degree rotational thrust, enabling precise maneuverability and propulsion efficiency, typically used for dynamic positioning and steering in larger vessels. Tunnel thrusters are fixed transverse thrusters installed in a tunnel through the hull, delivering lateral thrust mainly for docking and slow-speed maneuvers. The key difference lies in azimuth thrusters' full rotational capability versus tunnel thrusters' limited lateral thrust, impacting vessel control and operational flexibility.

Maneuverability and Vessel Control Comparison

Azimuth thrusters provide superior maneuverability by allowing 360-degree rotation, enabling precise vessel control during docking and tight navigation. Tunnel thrusters, installed transversely in the bow or stern, offer strong lateral thrust but with limited directional flexibility compared to azimuth thrusters. Your vessel's control efficiency improves significantly with azimuth thrusters due to their ability to generate thrust in any direction instantly.

Efficiency and Power Consumption Analysis

Azimuth thrusters offer higher maneuverability and efficiency by providing 360-degree rotation, allowing precise vessel positioning with optimized power use, especially beneficial for dynamic positioning systems. Tunnel thrusters, typically fixed in position, consume more power during lateral movements due to less efficient hydrodynamic flow and limited directional control. Your choice between azimuth and tunnel thrusters will significantly impact fuel consumption and overall operational efficiency depending on vessel size and maneuverability requirements.

Installation and Maintenance Considerations

Azimuth thrusters require complex integration into the hull structure, involving precise alignment and reinforcement to withstand steering loads, which can increase installation time and costs compared to tunnel thrusters. Tunnel thrusters are installed transversely within the bow or stern sections and typically offer easier access for inspection and maintenance, making them a practical choice for vessels prioritizing straightforward upkeep. Your decision should weigh the installation complexity of azimuth thrusters against the simpler maintenance profile of tunnel thrusters based on operational requirements.

Applications in Marine Industry

Azimuth thrusters provide enhanced maneuverability and propulsion efficiency for large vessels such as container ships, offshore supply vessels, and cruise ships, enabling precise directional control and dynamic positioning in open waters. Tunnel thrusters are primarily installed in the bow or stern of smaller vessels like tugs, ferries, and yachts, facilitating lateral movement for docking and close-quarters operations in ports and harbors. Both thruster types significantly improve vessel handling capabilities, with azimuth thrusters being favored for deep-sea navigation and tunnel thrusters optimized for low-speed maneuvering in confined marine environments.

Cost Comparison: Azimuth vs Tunnel Thrusters

Azimuth thrusters typically incur higher initial costs due to their complex design and advanced maneuvering capabilities, whereas tunnel thrusters are generally more affordable but offer limited directional control. Maintenance expenses for azimuth thrusters can be greater, driven by their mechanical complexity and exposure to harsher operational demands. Your choice between azimuth and tunnel thrusters should consider both upfront investment and long-term operational efficiency based on vessel requirements.

Choosing the Right Thruster for Your Vessel

Selecting the ideal thruster depends on vessel type, maneuverability needs, and operating environment. Azimuth thrusters offer 360-degree rotation for superior agility and precise steering in dynamic marine conditions, making them suitable for large ships and offshore vessels. Tunnel thrusters provide lateral thrust primarily for docking and low-speed maneuvering, fitting well with smaller boats or vessels operating in confined ports.

Azimuth thruster vs tunnel thruster Infographic

libmatt.com

libmatt.com