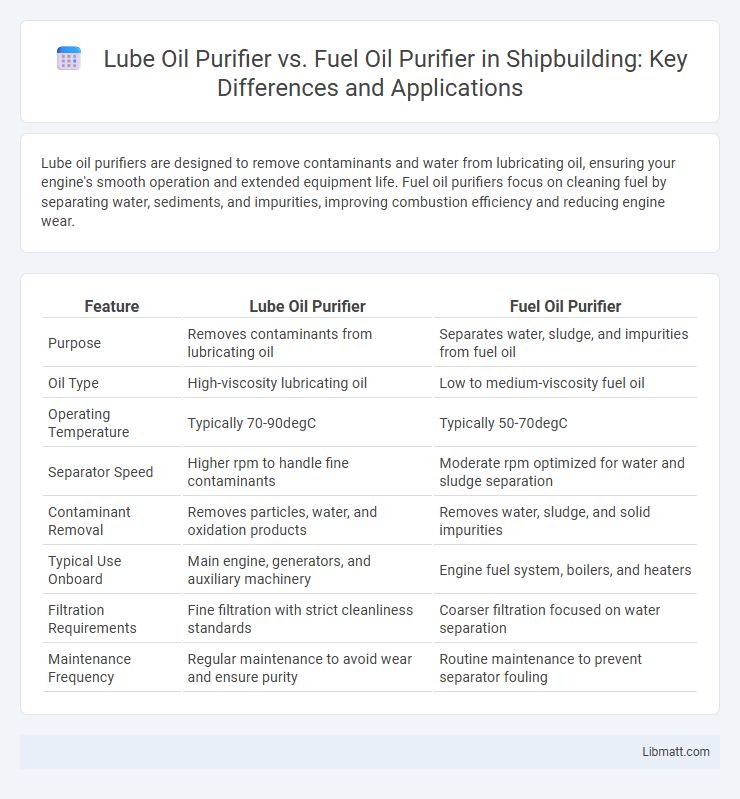

Lube oil purifiers are designed to remove contaminants and water from lubricating oil, ensuring your engine's smooth operation and extended equipment life. Fuel oil purifiers focus on cleaning fuel by separating water, sediments, and impurities, improving combustion efficiency and reducing engine wear.

Table of Comparison

| Feature | Lube Oil Purifier | Fuel Oil Purifier |

|---|---|---|

| Purpose | Removes contaminants from lubricating oil | Separates water, sludge, and impurities from fuel oil |

| Oil Type | High-viscosity lubricating oil | Low to medium-viscosity fuel oil |

| Operating Temperature | Typically 70-90degC | Typically 50-70degC |

| Separator Speed | Higher rpm to handle fine contaminants | Moderate rpm optimized for water and sludge separation |

| Contaminant Removal | Removes particles, water, and oxidation products | Removes water, sludge, and solid impurities |

| Typical Use Onboard | Main engine, generators, and auxiliary machinery | Engine fuel system, boilers, and heaters |

| Filtration Requirements | Fine filtration with strict cleanliness standards | Coarser filtration focused on water separation |

| Maintenance Frequency | Regular maintenance to avoid wear and ensure purity | Routine maintenance to prevent separator fouling |

Introduction to Purifiers: Lube Oil vs Fuel Oil

Lube oil purifiers and fuel oil purifiers serve critical roles in maintaining engine efficiency by removing contaminants from oils used in machinery. Lube oil purifiers focus on extracting water, sludge, and wear metals to protect engine components, ensuring your lubrication system remains clean and effective. Fuel oil purifiers concentrate on separating water, sediment, and impurities from fuel, enhancing combustion quality and preventing engine damage.

Importance of Oil Purification in Marine and Industrial Applications

Oil purification is crucial in marine and industrial applications to ensure the longevity and efficiency of machinery by removing contaminants such as water, sludge, and metal particles. Lube oil purifiers focus on maintaining the quality of lubricating oil, preventing engine wear and reducing maintenance costs, while fuel oil purifiers enhance combustion efficiency and reduce emissions by cleaning fuel oil. Effective purification extends equipment lifespan, optimizes performance, and minimizes operational downtime in both marine vessels and heavy industrial systems.

Core Functions: Lube Oil Purifiers Explained

Lube oil purifiers are designed primarily to remove contaminants such as water, sludge, and abrasive particles from lubricating oil, ensuring engine efficiency and longevity. These purifiers use centrifugal force to separate impurities while preserving essential additives and maintaining oil viscosity. Unlike fuel oil purifiers, which focus on separating water and sediments from fuel to optimize combustion, lube oil purifiers specifically target the cleanliness and quality of lubricating oil to protect engine components.

Core Functions: Fuel Oil Purifiers Explained

Fuel oil purifiers primarily separate water, sludge, and contaminants from heavy fuel oil to ensure cleaner combustion and protect engine components from wear and corrosion. Unlike lube oil purifiers that focus on maintaining the viscosity and cleanliness of lubricating oil to prolong engine life, fuel oil purifiers optimize fuel quality for efficient burning and reduced emissions. They employ centrifugal force to effectively remove impurities, improving fuel combustion efficiency and safeguarding fuel injection systems.

Key Differences Between Lube Oil and Fuel Oil Purifiers

Lube oil purifiers are designed to remove contaminants such as water, sludge, and solid particles from lubricating oil to ensure efficient engine performance and extended machinery life. Fuel oil purifiers focus on separating impurities like sediments, water, and combustion residues from fuel oil to improve fuel quality and prevent engine damage. Your choice between the two depends on whether the primary goal is maintaining lubrication system cleanliness or optimizing fuel combustion efficiency.

Working Principles: Centrifugal Separation Mechanisms

Lube oil purifiers and fuel oil purifiers both rely on centrifugal separation mechanisms to remove contaminants, but they operate with different fluid properties and contamination types. Lube oil purifiers focus on separating water, sludge, and solid particles from viscous lubricating oil, employing precise rotor speeds to optimize particle settling based on density differences. Fuel oil purifiers handle heavier fuel oil residues, using high rotational velocities to efficiently separate water and heavy sediments, ensuring cleaner fuel for combustion systems and protecting engine components.

Design Features Unique to Each Purifier Type

Lube oil purifiers feature advanced centrifugal separation mechanisms designed to remove fine contaminants and water from lubricating oils, ensuring optimal engine protection and longevity. Fuel oil purifiers prioritize high-capacity sludge removal and water separation to maintain combustion efficiency and reduce engine wear from impurities. Your choice should consider these distinct design features to match the specific oil purification needs of your equipment.

Technical Specifications and Performance Comparison

Lube oil purifiers typically operate at higher centrifuge speeds, ranging from 3,000 to 4,000 RPM, to effectively remove fine contaminants and water from lubricants, ensuring optimal engine performance. Fuel oil purifiers are designed to handle heavier contaminants and larger particle sizes, often featuring robust separation capacity with flow rates between 5 to 30 cubic meters per hour depending on the model. Your choice should consider the purifier's efficiency in contaminant removal, flow capacity, and compatibility with the specific oil type to maximize operational reliability and equipment longevity.

Maintenance and Operational Considerations

Lube oil purifiers require regular monitoring of filtration elements and timely replacement to maintain optimal viscosity and prevent engine wear, while fuel oil purifiers demand vigilant handling of heavier contaminants and sludge to ensure efficient combustion and avoid injector clogging. Operational considerations for lube oil purifiers emphasize maintaining temperature control and consistent flow rates to protect engine components, whereas fuel oil purifiers must adapt to varying fuel qualities and maintain sludge discharge systems for continuous performance. Your maintenance routine should account for these differences to maximize purifier efficiency and extend equipment lifespan.

Choosing the Right Purifier for Your Application

Lube oil purifiers are designed to remove water, sludge, and impurities from lubricating oils, ensuring optimal engine performance and longevity, while fuel oil purifiers focus on separating water and solid contaminants from fuel, enhancing combustion efficiency and reducing maintenance costs. Selecting the right purifier depends on your specific application requirements, such as the type of oil, contamination levels, and desired purity standards. Ensuring you choose the appropriate purifier for lube oil or fuel oil significantly improves system reliability and operational efficiency.

Lube oil purifier vs fuel oil purifier Infographic

libmatt.com

libmatt.com