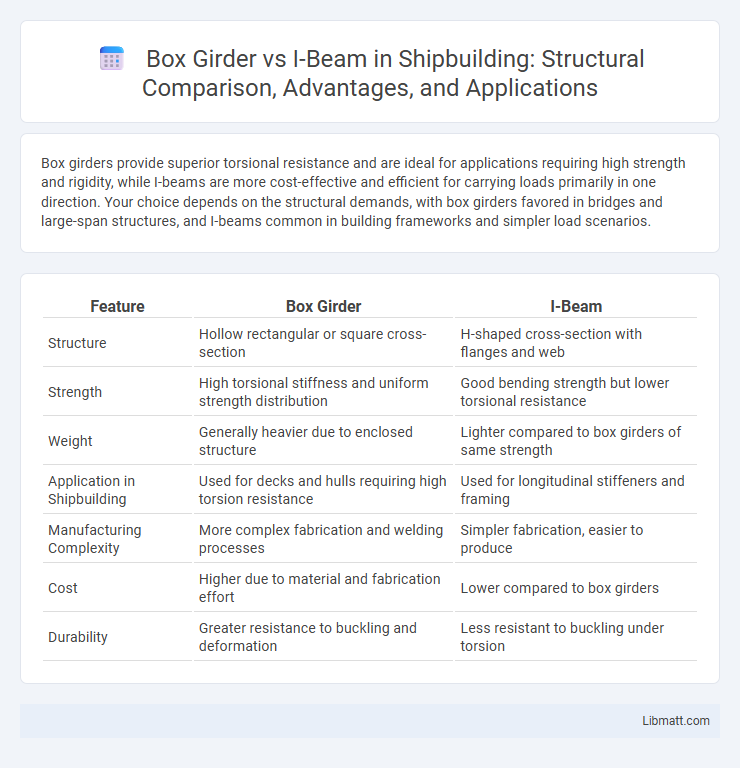

Box girders provide superior torsional resistance and are ideal for applications requiring high strength and rigidity, while I-beams are more cost-effective and efficient for carrying loads primarily in one direction. Your choice depends on the structural demands, with box girders favored in bridges and large-span structures, and I-beams common in building frameworks and simpler load scenarios.

Table of Comparison

| Feature | Box Girder | I-Beam |

|---|---|---|

| Structure | Hollow rectangular or square cross-section | H-shaped cross-section with flanges and web |

| Strength | High torsional stiffness and uniform strength distribution | Good bending strength but lower torsional resistance |

| Weight | Generally heavier due to enclosed structure | Lighter compared to box girders of same strength |

| Application in Shipbuilding | Used for decks and hulls requiring high torsion resistance | Used for longitudinal stiffeners and framing |

| Manufacturing Complexity | More complex fabrication and welding processes | Simpler fabrication, easier to produce |

| Cost | Higher due to material and fabrication effort | Lower compared to box girders |

| Durability | Greater resistance to buckling and deformation | Less resistant to buckling under torsion |

Introduction to Box Girders and I-Beams

Box girders consist of hollow, box-shaped cross-sections that provide superior torsional rigidity and strength, ideal for long-span bridges and structures requiring high load resistance. I-beams feature an I-shaped cross-section with flanges and a central web, optimized for bending and shear forces, commonly used in building frameworks and support systems. Your choice between box girders and I-beams depends on the structural demands, with box girders offering enhanced stability under twisting loads and I-beams providing efficient material use for vertical load-bearing.

Structural Design Differences

Box girders feature a hollow, rectangular cross-section that provides superior torsional stiffness and resistance to twisting, making them ideal for curved or heavily loaded bridges. I-beams consist of two horizontal flanges connected by a vertical web, optimizing material use for bending and shear forces in straightforward support applications. The closed shape of box girders enhances stability and load distribution, while the open I-beam design is simpler and more cost-effective for linear, uniformly loaded structures.

Material Usage and Cost Comparison

Box girders typically require more material than I-beams due to their closed-section design, resulting in higher initial costs. I-beams offer a more material-efficient solution for bending loads but may necessitate additional reinforcement to handle torsional forces, impacting total expenses. Choosing between the two involves balancing material quantity with structural performance requirements to optimize cost-effectiveness.

Load Bearing Capabilities

Box girders provide superior load-bearing capabilities compared to I-beams due to their closed cross-sectional shape, which offers enhanced torsional resistance and distributes stress more evenly. I-beams excel in supporting vertical loads but are more susceptible to twisting under uneven or lateral loads, making box girders preferable for bridges and structures requiring high stability. Your choice should consider the specific load conditions and structural demands to maximize safety and performance.

Applications in Construction

Box girders offer superior torsional rigidity and are widely used in bridge construction, long-span roofs, and elevated highways where structural stability under complex loads is crucial. I-beams are preferred in building frameworks, industrial structures, and residential construction due to their efficient load-bearing capacity in vertical and bending applications. Both components optimize material usage but target different load conditions and design requirements in construction projects.

Advantages of Box Girders

Box girders provide superior torsional rigidity compared to I-beams, making them ideal for structures subjected to twisting forces. Their closed cross-section enhances resistance to lateral buckling and allows for longer spans without intermediate supports. The aerodynamic shape of box girders also reduces wind-induced vibrations, improving structural stability in bridge and building applications.

Advantages of I-Beams

I-beams offer superior strength-to-weight ratios, making them ideal for structural applications requiring high load-bearing capacity with minimal material use. Their open cross-section provides easier access for welding, bolting, and connecting other components, enhancing construction efficiency. You benefit from their widespread availability and versatility in various types of building and bridge frameworks.

Installation and Maintenance Considerations

Box girders offer enhanced torsional rigidity, making them easier to align during installation compared to I-beams, which require careful positioning to prevent twisting. Maintenance of box girders is often simpler due to their enclosed structure that protects internal components from environmental damage, whereas I-beams are more exposed and may require frequent inspections for corrosion and surface wear. Both types demand specialized equipment and skilled labor, but box girders typically incur higher upfront costs balanced by potentially lower long-term maintenance expenses.

Durability and Lifespan

Box girders offer superior durability and lifespan compared to I-beams due to their closed cross-sectional design, which provides enhanced resistance to torsion and bending stresses. The enclosed shape minimizes corrosion and fatigue damage, extending the structural integrity over time, especially in harsh environmental conditions. Choosing box girders for your project ensures long-term performance and reduced maintenance costs.

Choosing the Right Girder for Your Project

Box girders offer superior torsional resistance and are ideal for long-span bridges requiring high strength and rigidity, while I-beams provide efficient load distribution with lower weight, making them suitable for shorter spans and lighter loads. The choice between a box girder and an I-beam depends on project-specific factors such as span length, load requirements, budget, and construction complexity. Evaluating structural performance, material costs, and maintenance needs ensures the selection of the optimal girder type for maximum durability and efficiency.

Box girder vs I-beam Infographic

libmatt.com

libmatt.com