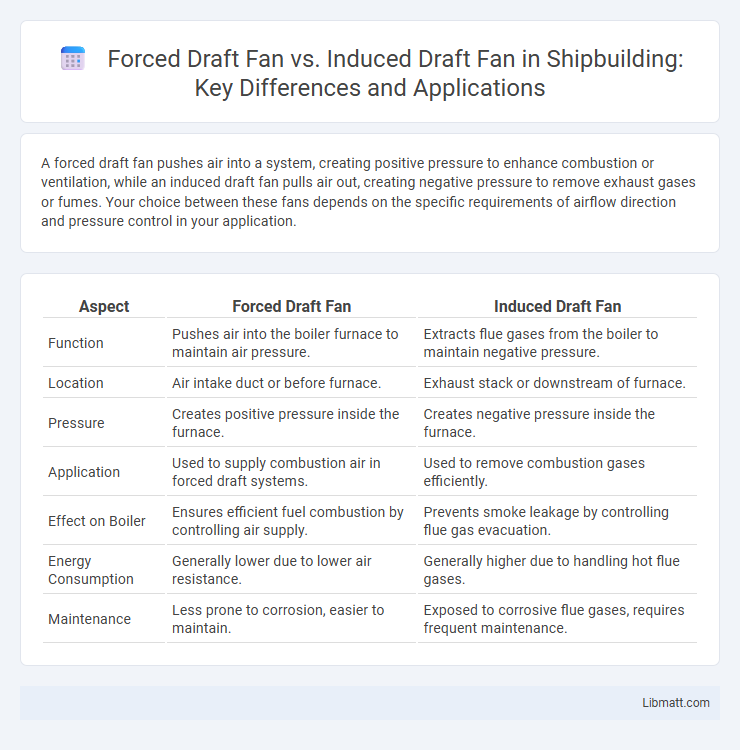

A forced draft fan pushes air into a system, creating positive pressure to enhance combustion or ventilation, while an induced draft fan pulls air out, creating negative pressure to remove exhaust gases or fumes. Your choice between these fans depends on the specific requirements of airflow direction and pressure control in your application.

Table of Comparison

| Aspect | Forced Draft Fan | Induced Draft Fan |

|---|---|---|

| Function | Pushes air into the boiler furnace to maintain air pressure. | Extracts flue gases from the boiler to maintain negative pressure. |

| Location | Air intake duct or before furnace. | Exhaust stack or downstream of furnace. |

| Pressure | Creates positive pressure inside the furnace. | Creates negative pressure inside the furnace. |

| Application | Used to supply combustion air in forced draft systems. | Used to remove combustion gases efficiently. |

| Effect on Boiler | Ensures efficient fuel combustion by controlling air supply. | Prevents smoke leakage by controlling flue gas evacuation. |

| Energy Consumption | Generally lower due to lower air resistance. | Generally higher due to handling hot flue gases. |

| Maintenance | Less prone to corrosion, easier to maintain. | Exposed to corrosive flue gases, requires frequent maintenance. |

Introduction to Draft Fans in Industrial Systems

Draft fans are essential components in industrial systems for controlling airflow and maintaining optimal combustion conditions in boilers and furnaces. Forced draft fans supply pressurized air directly into the combustion chamber to enhance fuel burning efficiency, while induced draft fans extract flue gases, promoting negative pressure and ensuring the removal of exhaust gases. These fans optimize thermal performance, improve emissions control, and maintain system safety by regulating airflow dynamics in various industrial processes.

What is a Forced Draft Fan?

A forced draft fan is a mechanical device that pushes air into a furnace or combustion chamber to maintain efficient airflow and combustion. It creates positive pressure by forcing air through the air intake, ensuring a consistent supply of oxygen to support fuel burning. This fan is commonly used in industrial boilers and HVAC systems to optimize combustion efficiency and control emissions.

What is an Induced Draft Fan?

An induced draft fan is a mechanical device used in industrial systems to extract flue gases or exhaust air from boilers, furnaces, or chimneys. It operates by creating a negative pressure inside the combustion chamber, pulling gases through the system to the stack for safe expulsion. Induced draft fans enhance combustion efficiency, reduce back pressure, and help control emissions by maintaining proper airflow and gas flow direction.

Key Differences Between Forced and Induced Draft Fans

Forced draft fans push air into the furnace or combustion chamber, creating positive pressure that ensures efficient fuel combustion and consistent airflow. Induced draft fans pull flue gases out of the furnace, generating negative pressure that helps remove combustion byproducts and maintain optimal exhaust flow. The primary difference lies in their operational direction--forced draft fans supply air inbound, while induced draft fans extract air outbound--impacting energy consumption and system design in HVAC and industrial applications.

How Forced Draft Fans Work in Practice

Forced draft fans operate by pushing air into a combustion chamber under pressure, creating a positive pressure environment that ensures a consistent airflow to support efficient fuel combustion. These fans are typically positioned at the air intake side, utilizing centrifugal or axial blades to generate the necessary volume and pressure of air for boilers, furnaces, or industrial processes. By maintaining controlled air delivery, forced draft fans enhance combustion efficiency, reduce fuel consumption, and improve overall system performance.

How Induced Draft Fans Operate

Induced draft fans operate by creating negative pressure to draw flue gases out of a furnace or boiler, enhancing combustion efficiency and maintaining stable airflow. These fans are positioned downstream of the combustion chamber, pulling exhaust gases through the system and expelling them safely through the chimney. Your industrial processes benefit from induced draft fans by improving emission control and optimizing fuel combustion.

Efficiency Comparison: Forced Draft vs. Induced Draft Fans

Forced draft fans generally exhibit higher efficiency in delivering air at positive pressure, optimizing combustion processes in industrial boilers by ensuring a consistent air supply. Induced draft fans operate under negative pressure, which often results in lower energy consumption for exhausting gases but slightly reduced overall efficiency due to pressure losses in the flue system. The efficiency comparison depends on application-specific factors such as system pressure, airflow requirements, and thermal performance, with forced draft fans favored for controlled air introduction and induced draft fans preferred for effective flue gas removal.

Applications of Forced Draft Fans

Forced draft fans are commonly used in boiler systems to supply fresh, pressurized air for combustion, ensuring efficient fuel burning and optimal thermal performance. These fans are essential in industries requiring controlled airflow, such as power plants, furnaces, and kilns, where maintaining proper air pressure enhances operational safety and energy efficiency. You can rely on forced draft fans to improve air distribution in HVAC systems, aiding in ventilation and pollutant control in large industrial facilities.

Applications of Induced Draft Fans

Induced draft fans are primarily used in industrial applications such as boilers, furnaces, and chimneys where they draw flue gases out to maintain proper combustion and control emissions. These fans efficiently handle high-temperature, corrosive gases and are critical in pollution control systems like electrostatic precipitators and scrubbers. Their ability to maintain negative pressure makes them ideal for applications requiring precise airflow regulation and safe exhaust of hazardous fumes.

Choosing the Right Draft Fan for Your System

Selecting the right draft fan for your system depends on factors such as airflow requirements, pressure conditions, and system design. Forced draft fans push air into the combustion chamber, providing positive pressure and better control for optimized fuel combustion. Induced draft fans pull exhaust gases out, creating negative pressure and improving flue gas expulsion, which is crucial for maintaining safe and efficient operation.

Forced draft fan vs induced draft fan Infographic

libmatt.com

libmatt.com