Seam welds create continuous joints by overlapping and fusing two metal surfaces, offering enhanced leak-proof strength ideal for pressure vessels and pipes, while butt welds join two pieces end-to-end, providing a smooth, strong connection often used in structural applications. You should choose seam welds for applications requiring durability against fluid or gas leakage, and butt welds when a flush, straight joint is essential.

Table of Comparison

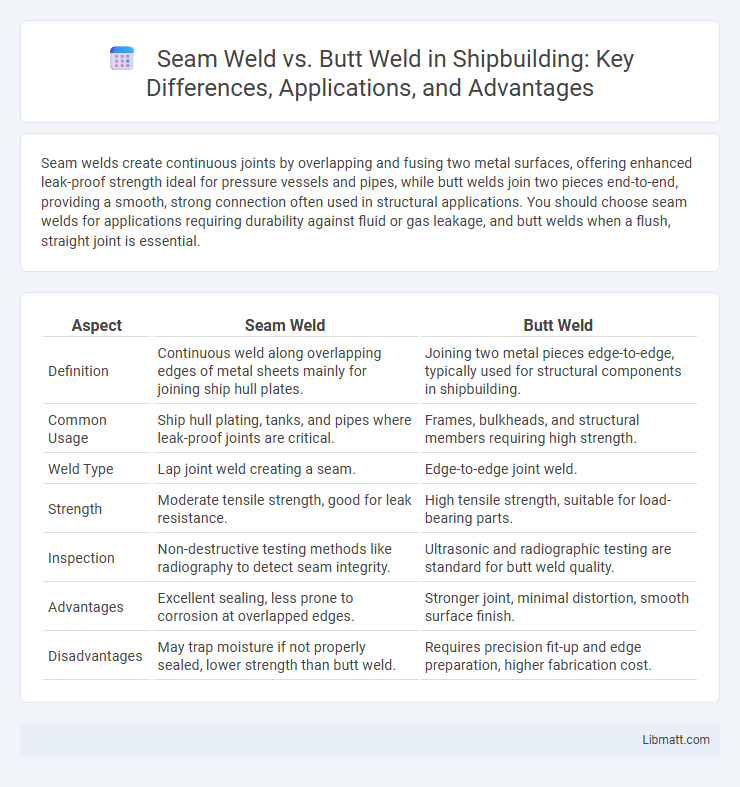

| Aspect | Seam Weld | Butt Weld |

|---|---|---|

| Definition | Continuous weld along overlapping edges of metal sheets mainly for joining ship hull plates. | Joining two metal pieces edge-to-edge, typically used for structural components in shipbuilding. |

| Common Usage | Ship hull plating, tanks, and pipes where leak-proof joints are critical. | Frames, bulkheads, and structural members requiring high strength. |

| Weld Type | Lap joint weld creating a seam. | Edge-to-edge joint weld. |

| Strength | Moderate tensile strength, good for leak resistance. | High tensile strength, suitable for load-bearing parts. |

| Inspection | Non-destructive testing methods like radiography to detect seam integrity. | Ultrasonic and radiographic testing are standard for butt weld quality. |

| Advantages | Excellent sealing, less prone to corrosion at overlapped edges. | Stronger joint, minimal distortion, smooth surface finish. |

| Disadvantages | May trap moisture if not properly sealed, lower strength than butt weld. | Requires precision fit-up and edge preparation, higher fabrication cost. |

Introduction to Seam Welds and Butt Welds

Seam welds create continuous joints by overlapping two metal sheets and welding along the seam to ensure a leak-proof and strong bond, commonly used in pipe manufacturing and pressure vessels. Butt welds join two metal pieces edge-to-edge, providing a smooth, uniform surface ideal for structural applications where strength and aesthetics matter. Understanding the differences between seam weld and butt weld techniques helps you select the appropriate welding method based on material thickness, strength requirements, and intended use.

Definition and Basic Concepts

Seam weld is a continuous welding process where overlapping edges are joined by applying heat and pressure, commonly used in pipe and tube fabrication to create leak-proof joints. Butt weld involves joining two pieces of metal end-to-end in the same plane, typically used for structural applications requiring strong, load-bearing joints. Both techniques differ in weld configuration and application methods, impacting their suitability for various industrial uses.

Construction and Techniques

Seam welds are created by continuously welding along the joint using techniques like rotary or continuous TIG welding, primarily for tubular or sheet metal applications where a leak-proof seal is essential. Butt welds join two pieces edge-to-edge using methods such as MIG, TIG, or stick welding, ensuring a strong, flush connection for structural components. Both techniques require precise preparation and alignment, but seam welds emphasize creating a consistent, uninterrupted weld bead, while butt welds focus on penetrating the joint for maximum strength.

Strength and Structural Integrity

Seam welds provide continuous, uniform bonding along the joint, enhancing resistance to shear forces and reducing the risk of leakage, making them ideal for pressure vessels and pipelines. Butt welds offer high tensile strength and excellent load-bearing capacity by fusing two pieces edge-to-edge, commonly used in structural applications requiring robust joint performance. Both welding types ensure structural integrity, but the choice depends on specific stress conditions and the need for crack resistance or fluid containment.

Common Applications

Seam welds are commonly used in applications requiring continuous, airtight, or watertight joints such as in automotive fuel tanks, metal roofing, and pipe manufacturing. Butt welds are prevalent in structural steel fabrication, pressure vessels, and pipeline construction due to their strong, full-penetration joint capability. Both welding techniques serve critical roles in industries like aerospace, shipbuilding, and heavy machinery, aligning with specific strength and sealing requirements.

Material Compatibility

Seam welds excel in joining thin metal sheets, especially in automotive and appliance manufacturing, where materials like stainless steel and aluminum are common. Butt welds provide strong joints ideal for thicker, structural materials such as carbon steel and alloy steel, ensuring high strength and durability. Your choice between seam weld and butt weld depends on the material thickness and type, directly impacting the weld quality and application.

Advantages of Seam Welds

Seam welds provide continuous, airtight joints ideal for applications requiring leak-proof seals and enhanced structural integrity. They offer superior resistance to corrosion and fatigue compared to butt welds, making them ideal for pipelines and pressure vessels. Their automated welding process ensures consistent quality and faster production rates in manufacturing environments.

Benefits of Butt Welds

Butt welds provide superior joint strength and a continuous, uniform weld that enhances structural integrity in metal fabrication. They allow for full penetration welding, resulting in a more reliable and durable connection compared to seam welds, which often involve surface or partial thickness joining. Butt welds are commonly used in high-stress applications such as pipelines, pressure vessels, and automotive components due to their excellent load-bearing capacity and resistance to fatigue.

Key Differences Between Seam and Butt Welds

Seam welds create continuous, leak-proof joints along sheet metal edges using roller electrodes, ideal for circular or tubular components in industries like automotive and pressure vessels. Butt welds join two metal pieces end-to-end, providing strong structural integrity for pipes, plates, and heavy fabrication projects by welding along the joint's perimeter or bevel. Key differences include the welding technique--seam welding employing resistance and continuous rolling, while butt welding relies on fusion of abutting edges--resulting in distinct applications and mechanical properties.

Choosing the Right Weld for Your Project

Selecting the appropriate weld type depends on the specific project requirements, with seam welds ideal for continuous, leak-proof joints in thin materials, while butt welds provide strong, structural connections for thicker components. Seam welds excel in applications requiring airtight or watertight seals, often used in piping or sheet metal fabrication. Butt welds offer superior strength and penetration, making them suitable for heavy-duty construction and manufacturing where load-bearing capacity is critical.

Seam weld vs butt weld Infographic

libmatt.com

libmatt.com