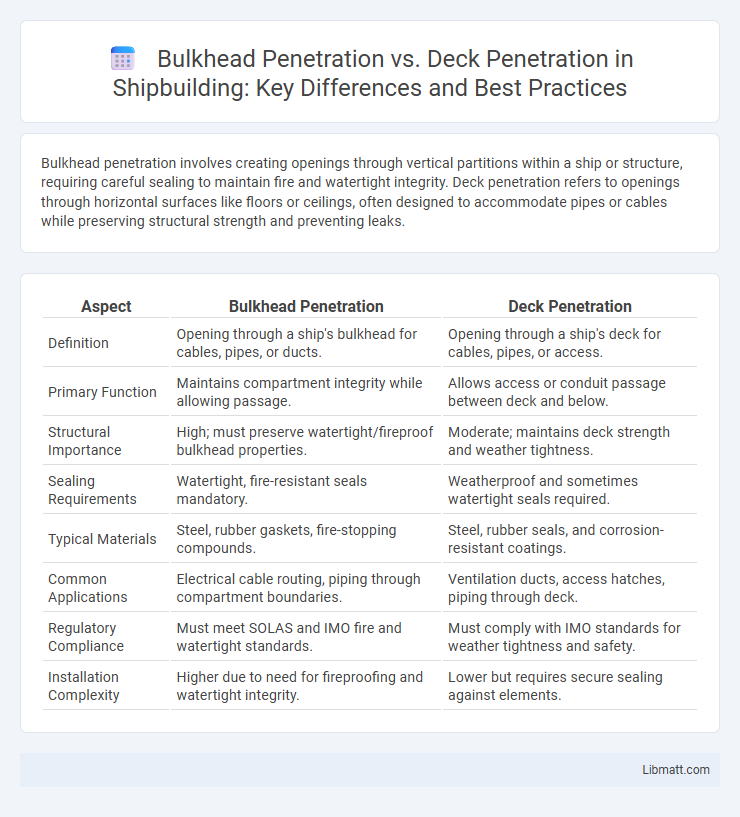

Bulkhead penetration involves creating openings through vertical partitions within a ship or structure, requiring careful sealing to maintain fire and watertight integrity. Deck penetration refers to openings through horizontal surfaces like floors or ceilings, often designed to accommodate pipes or cables while preserving structural strength and preventing leaks.

Table of Comparison

| Aspect | Bulkhead Penetration | Deck Penetration |

|---|---|---|

| Definition | Opening through a ship's bulkhead for cables, pipes, or ducts. | Opening through a ship's deck for cables, pipes, or access. |

| Primary Function | Maintains compartment integrity while allowing passage. | Allows access or conduit passage between deck and below. |

| Structural Importance | High; must preserve watertight/fireproof bulkhead properties. | Moderate; maintains deck strength and weather tightness. |

| Sealing Requirements | Watertight, fire-resistant seals mandatory. | Weatherproof and sometimes watertight seals required. |

| Typical Materials | Steel, rubber gaskets, fire-stopping compounds. | Steel, rubber seals, and corrosion-resistant coatings. |

| Common Applications | Electrical cable routing, piping through compartment boundaries. | Ventilation ducts, access hatches, piping through deck. |

| Regulatory Compliance | Must meet SOLAS and IMO fire and watertight standards. | Must comply with IMO standards for weather tightness and safety. |

| Installation Complexity | Higher due to need for fireproofing and watertight integrity. | Lower but requires secure sealing against elements. |

Introduction to Bulkhead and Deck Penetrations

Bulkhead penetration refers to the process of creating openings through bulkheads, which are vertical partitions in ships or buildings designed to provide structural support and compartmentalization. Deck penetration involves making openings through decks, the horizontal surfaces or floors that separate different levels within a structure. Both types of penetrations require careful sealing and reinforcement to maintain the integrity and safety of the structure while allowing the passage of pipes, cables, or other utilities.

Defining Bulkhead Penetration

Bulkhead penetration refers to the process of creating openings in vertical partitions, such as walls or bulkheads, to allow the passage of pipes, cables, or ductwork while maintaining fire and watertight integrity. Unlike deck penetration, which involves openings in horizontal surfaces, bulkhead penetration requires specialized sealing materials and techniques to prevent leakage and preserve structural safety. Understanding the differences between bulkhead and deck penetrations is crucial for ensuring your marine or industrial installation complies with safety standards and operational efficiency.

Understanding Deck Penetration

Deck penetration involves creating openings in a ship's deck to allow pipes, cables, or equipment to pass through while maintaining the structural integrity and watertightness of the vessel. Unlike bulkhead penetration, which focuses on vertical partitions, deck penetration must ensure resistance against water ingress and withstand dynamic loads from deck operations. Proper sealing and reinforcement techniques are critical in deck penetration to comply with maritime safety standards and prevent corrosion or structural failure.

Key Differences Between Bulkhead and Deck Penetration

Bulkhead penetration involves creating openings through vertical partitions within a ship or structure, while deck penetration refers to holes made through horizontal surfaces like floors or ceilings. The key differences lie in their structural impacts and sealing requirements; bulkhead penetrations often require fireproofing and watertight seals to maintain compartment integrity, whereas deck penetrations focus on load distribution and preventing leaks. Understanding these distinctions ensures your design maintains safety, stability, and compliance with maritime or building regulations.

Common Applications of Bulkhead Penetrations

Bulkhead penetrations are commonly used in maritime and aerospace industries to allow pipes, cables, and ducts to pass through watertight or fire-resistant bulkheads while maintaining structural integrity and safety standards. These penetrations are essential for compartmentalization, helping to prevent the spread of fire, water, or gases between different sections of a vessel or aircraft. Your systems' compliance with safety regulations often depends on properly installed bulkhead penetrations to ensure operational reliability and protection.

Typical Uses of Deck Penetrations

Deck penetrations are commonly used to provide access for piping, cables, and ventilation systems through ship decks, allowing for the secure passage of essential utilities while maintaining structural integrity. These penetrations are critical in areas requiring watertight or weather-tight sealing to prevent water ingress in marine and offshore applications. You can optimize safety and functionality by selecting appropriate deck penetration types based on load requirements and environmental conditions.

Safety and Regulatory Requirements

Bulkhead penetration and deck penetration each require strict adherence to safety and regulatory standards to ensure structural integrity and prevent fire or fluid leaks. Bulkhead penetrations must comply with fire-resistance ratings and sealing protocols specified by maritime or building codes to maintain compartmentalization and prevent hazard spread. Your choice between the two should prioritize certified materials and installation methods that meet the relevant safety regulations to reduce risks and enhance protection.

Installation Practices and Techniques

Bulkhead penetration installation requires careful sealing around pipes or cables to maintain fire resistance and watertight integrity, often using firestop materials and gaskets designed to withstand pressure differences between compartments. Deck penetration involves securing the pipe or conduit through the horizontal surface, demanding precise alignment and robust sealing techniques such as flanged collars, expansion joints, and waterproof membranes to prevent leaks and accommodate ship movement. Both installations necessitate adherence to marine safety standards, with bulkhead penetration focusing on compartmentalization and deck penetration emphasizing structural integrity and weatherproofing.

Maintenance and Inspection Tips

Regular maintenance of bulkhead penetration involves checking for corrosion, seals integrity, and ensuring watertight barriers remain effective to prevent leaks or structural damage. Deck penetration inspections should focus on sealant condition, potential cracks around fittings, and signs of corrosion to maintain waterproofing and safety. Using specialized tools like borescopes and moisture meters enhances detection of hidden issues in both bulkhead and deck penetrations.

Choosing Between Bulkhead and Deck Penetration Solutions

Selecting between bulkhead penetration and deck penetration solutions depends on the specific structural and environmental requirements of your project. Bulkhead penetrations provide effective sealing and support for cables or pipes passing through vertical barriers, while deck penetrations are designed for horizontal surfaces, ensuring waterproofing and load distribution. Understanding the load dynamics, fluid exposure, and space constraints helps determine the optimal choice for durability and safety.

Bulkhead penetration vs deck penetration Infographic

libmatt.com

libmatt.com