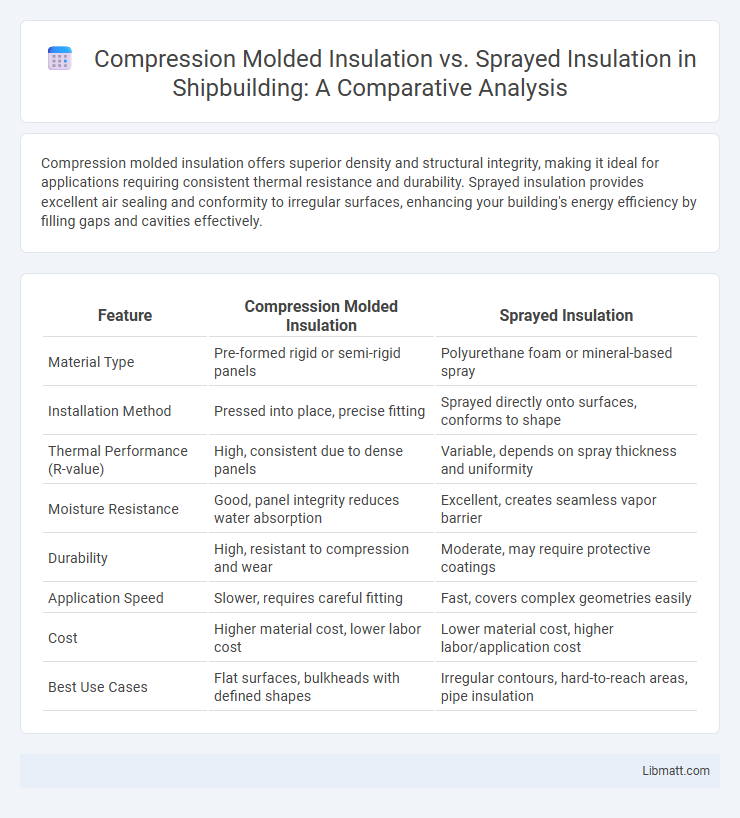

Compression molded insulation offers superior density and structural integrity, making it ideal for applications requiring consistent thermal resistance and durability. Sprayed insulation provides excellent air sealing and conformity to irregular surfaces, enhancing your building's energy efficiency by filling gaps and cavities effectively.

Table of Comparison

| Feature | Compression Molded Insulation | Sprayed Insulation |

|---|---|---|

| Material Type | Pre-formed rigid or semi-rigid panels | Polyurethane foam or mineral-based spray |

| Installation Method | Pressed into place, precise fitting | Sprayed directly onto surfaces, conforms to shape |

| Thermal Performance (R-value) | High, consistent due to dense panels | Variable, depends on spray thickness and uniformity |

| Moisture Resistance | Good, panel integrity reduces water absorption | Excellent, creates seamless vapor barrier |

| Durability | High, resistant to compression and wear | Moderate, may require protective coatings |

| Application Speed | Slower, requires careful fitting | Fast, covers complex geometries easily |

| Cost | Higher material cost, lower labor cost | Lower material cost, higher labor/application cost |

| Best Use Cases | Flat surfaces, bulkheads with defined shapes | Irregular contours, hard-to-reach areas, pipe insulation |

Introduction to Compression Molded and Sprayed Insulation

Compression molded insulation delivers high-density thermal barriers formed by pressing insulation materials into rigid panels, offering superior thermal performance and structural integrity. Sprayed insulation, such as spray foam, expands upon application to fill cavities and irregular surfaces, providing exceptional air sealing and moisture resistance. Both methods enhance energy efficiency, but choice depends on specific project requirements including application surface, desired R-value, and installation conditions.

Key Differences in Insulation Methods

Compression molded insulation offers high-density protection by compacting materials into precise shapes, resulting in consistent thermal performance and excellent structural integrity. Sprayed insulation, applied as a liquid foam that expands and hardens, provides superior air sealing and fills irregular cavities effectively, reducing energy loss and drafts. Key differences include installation technique, material density, thermal conductivity, and adaptability to complex surfaces.

Material Composition and Sustainability

Compression molded insulation typically consists of rigid foam boards made from polyisocyanurate or expanded polystyrene, offering high thermal resistance with less material waste during installation. Sprayed insulation, often composed of polyurethane foam or cellulose, provides excellent air sealing but may involve higher environmental impact due to chemical agents or biodegradability concerns. Your choice between compression molded and sprayed insulation should consider both the sustainability of materials and the specific energy efficiency goals of your project.

Installation Process Comparison

Compression molded insulation involves pre-formed panels that are precisely cut to fit spaces, enabling a faster, cleaner installation with reduced on-site labor and waste. Sprayed insulation requires specialized equipment to apply foam or cellulose directly onto surfaces, conforming to irregular shapes but often demanding longer curing times and more meticulous safety measures. Your choice depends on project complexity, as molded insulation offers speed and uniformity, while sprayed methods provide superior air sealing for intricate areas.

Thermal Performance and Energy Efficiency

Compression molded insulation offers higher thermal performance due to its dense composition, which reduces air gaps and enhances energy efficiency in your building. Sprayed insulation provides excellent coverage, sealing irregular spaces effectively but may have slightly lower R-values compared to molded options. Choosing compression molded insulation can lead to better long-term energy savings by minimizing heat transfer more efficiently.

Cost Analysis: Compression Molded vs. Sprayed

Compression molded insulation typically involves higher upfront manufacturing costs due to specialized equipment and materials but offers long-term savings with its durability and lower maintenance requirements. Sprayed insulation often has lower initial installation costs and provides excellent coverage in irregular spaces, though it may incur higher expenses over time due to potential settling or degradation. Your choice should weigh immediate budget constraints against lifecycle savings and performance needs.

Durability and Longevity

Compression molded insulation offers superior durability and longevity due to its dense structure, which resists settling and moisture absorption over time. Sprayed insulation can provide excellent initial coverage and air sealing but may degrade faster in humid or mechanical stress environments, potentially reducing its lifespan. Your choice should weigh compression molded insulation for long-term stability against sprayed insulation's versatility and quicker application.

Moisture and Mold Resistance Capabilities

Compression molded insulation offers superior moisture resistance due to its dense, impermeable structure that significantly reduces water absorption, thereby minimizing mold growth risks. In contrast, sprayed insulation, while effective for filling gaps and irregular spaces, tends to absorb moisture more readily, increasing susceptibility to mold if not properly protected by vapor barriers. Optimal moisture and mold resistance in insulation projects often require selecting compression molded materials in areas prone to high humidity or water exposure.

Application Suitability for Different Projects

Compression molded insulation is ideal for projects requiring precise thickness and high-density thermal barriers, such as automotive and electrical components, where uniformity and durability are critical. Sprayed insulation offers superior adaptability for irregular or complex surfaces, making it suitable for retrofit building insulation and sealing hard-to-reach areas. Project specifications dictate the choice: compression molding excels in controlled manufacturing environments, while sprayed insulation provides flexibility and quick application for on-site customization.

Environmental Impact and Green Certifications

Compression molded insulation typically has a lower environmental impact due to its dense composition, which enhances energy efficiency and reduces waste during installation. Sprayed insulation, while offering superior air sealing and thermal performance, may contain chemicals that affect indoor air quality and require verification for green certifications like GREENGUARD or LEED compliance. You should evaluate both options based on their sustainable materials, recyclability, and certification status to ensure your project aligns with environmental standards.

Compression molded insulation vs sprayed insulation Infographic

libmatt.com

libmatt.com