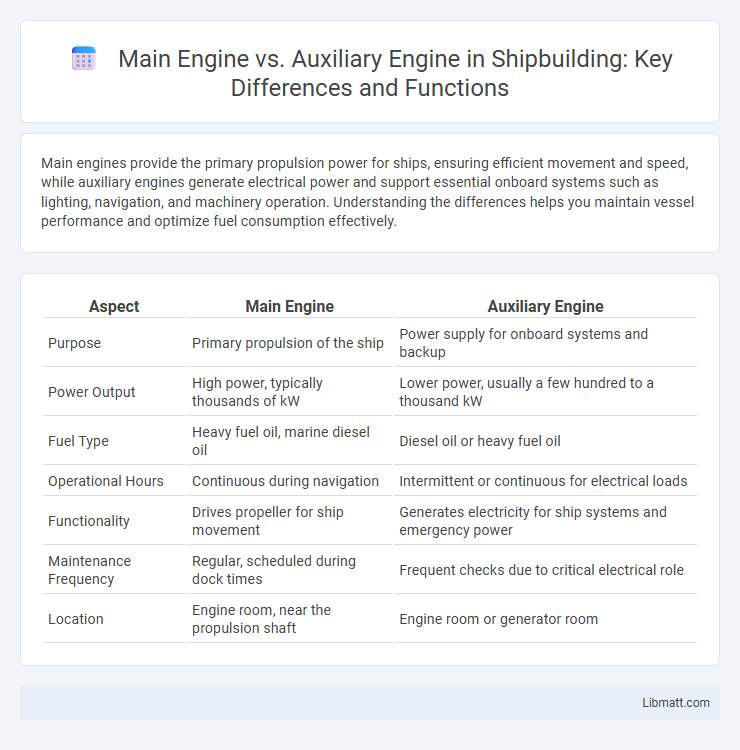

Main engines provide the primary propulsion power for ships, ensuring efficient movement and speed, while auxiliary engines generate electrical power and support essential onboard systems such as lighting, navigation, and machinery operation. Understanding the differences helps you maintain vessel performance and optimize fuel consumption effectively.

Table of Comparison

| Aspect | Main Engine | Auxiliary Engine |

|---|---|---|

| Purpose | Primary propulsion of the ship | Power supply for onboard systems and backup |

| Power Output | High power, typically thousands of kW | Lower power, usually a few hundred to a thousand kW |

| Fuel Type | Heavy fuel oil, marine diesel oil | Diesel oil or heavy fuel oil |

| Operational Hours | Continuous during navigation | Intermittent or continuous for electrical loads |

| Functionality | Drives propeller for ship movement | Generates electricity for ship systems and emergency power |

| Maintenance Frequency | Regular, scheduled during dock times | Frequent checks due to critical electrical role |

| Location | Engine room, near the propulsion shaft | Engine room or generator room |

Introduction to Main Engine and Auxiliary Engine

The main engine serves as the primary power source propelling a ship and converting fuel into mechanical energy for navigation. Auxiliary engines provide essential support functions such as generating electricity, powering pumps, compressors, and other onboard systems crucial for vessel operation. Both engines work in tandem to ensure efficient performance and safe maritime operation.

Key Functions of Main Engines

Main engines serve as the primary source of propulsion in ships, converting fuel into mechanical energy to drive the vessel's propellers efficiently over long distances. These powerful engines are designed to deliver high torque and maintain consistent speeds under varying loads, ensuring optimal fuel consumption and operational reliability. Understanding the key functions of main engines helps you optimize vessel performance and manage fuel costs effectively.

Roles of Auxiliary Engines on Ships

Auxiliary engines on ships provide essential power for non-propulsion functions such as running electrical generators, pumps, compressors, and other onboard machinery critical for daily operations. They support the main engine by ensuring continuous energy supply for systems like lighting, navigation equipment, and cargo handling, enhancing overall vessel efficiency and safety. Your ship's auxiliary engines maintain operational stability while the main engine drives propulsion.

Design Differences: Main vs Auxiliary Engines

Main engines are designed for continuous, high-power output required to propel large vessels, featuring robust construction and optimized fuel efficiency for long-distance maritime operation. Auxiliary engines are built for versatility and reliability, providing power for onboard systems, electrical generation, and emergency scenarios with variable loads and frequent start-stop cycles. You should understand that while main engines prioritize propulsion efficiency, auxiliary engines prioritize operational support and energy flexibility.

Fuel Types Used in Main and Auxiliary Engines

Main engines primarily use heavy fuel oil (HFO) or marine diesel oil (MDO) due to their high energy density and cost efficiency, enabling long voyages and heavy-duty operations. Auxiliary engines typically run on marine diesel oil (MDO) or marine gas oil (MGO), which offer cleaner combustion suitable for powering onboard electrical systems and auxiliary machinery. Your choice of fuel types affects engine performance, emissions, and operational costs, making it crucial to select fuels compatible with engine design and environmental regulations.

Power Output Comparison

Main engines typically deliver power outputs ranging from several thousand to tens of thousands of horsepower, driving the primary propulsion system of ships and large machinery. Auxiliary engines provide significantly lower power, usually between a few hundred to a few thousand horsepower, primarily supporting secondary functions such as electrical generation and onboard systems operation. The disparity in power output reflects their distinct roles, with main engines optimized for continuous high-load performance and auxiliary engines designed for versatility and efficiency in supporting tasks.

Applications: When to Use Each Engine Type

Main engines provide the primary propulsion power for ships, ideal for long voyages and heavy load conditions requiring continuous, high output. Auxiliary engines support onboard systems such as electricity generation, hydraulic power, and emergency backup, making them essential during docking, maneuvering, or when the main engine is offline. Your choice depends on operational needs: rely on the main engine for propulsion and on auxiliary engines for auxiliary power and system support.

Maintenance Requirements for Main and Auxiliary Engines

Maintenance requirements for main engines include regular inspections, oil changes, and performance monitoring to ensure optimal power output and fuel efficiency in marine or industrial applications. Auxiliary engines demand consistent upkeep such as lubrication, cooling system checks, and electrical system inspections to support essential functions like power generation and onboard systems. Both engine types require scheduled downtime for preventive maintenance to minimize breakdowns and extend operational lifespan.

Energy Efficiency: Main Engine vs Auxiliary Engine

Main engines in ships typically exhibit higher energy efficiency due to their optimized design for continuous operation at steady speeds, maximizing fuel consumption per unit of power output. Auxiliary engines, while essential for powering onboard systems and providing flexibility during variable loads, generally operate less efficiently as they frequently run under partial loads and fluctuating conditions. Advances in engine technology and hybrid systems aim to enhance auxiliary engines' efficiency, narrowing the energy efficiency gap between main and auxiliary propulsion systems.

Conclusion: Selecting the Right Engine for Maritime Needs

Choosing between a main engine and an auxiliary engine depends on your maritime operational requirements, as the main engine delivers primary propulsion power, while auxiliary engines support essential onboard systems and backup power. Evaluating factors such as fuel efficiency, power output, and vessel size ensures optimal engine selection tailored to your specific maritime needs. Prioritizing reliability and maintenance capabilities further guarantees enhanced vessel performance and operational safety.

Main engine vs auxiliary engine Infographic

libmatt.com

libmatt.com