Rated load refers to the maximum load a lifting device or equipment is designed to handle under ideal conditions, while safe working load (SWL) indicates the maximum permissible load that can be safely lifted considering a factor of safety to prevent accidents. Ensuring your operations adhere to the safe working load guidelines is crucial for maintaining safety and equipment longevity.

Table of Comparison

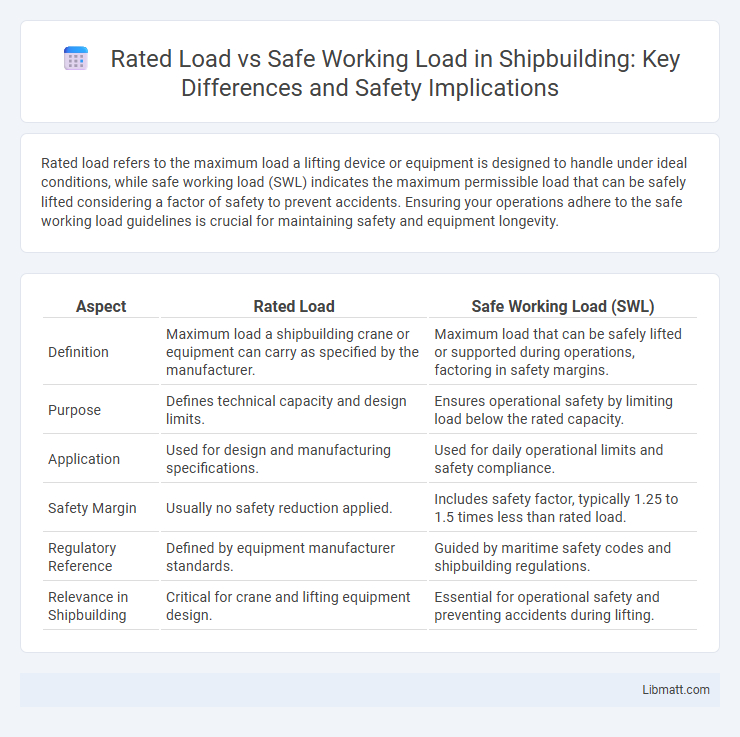

| Aspect | Rated Load | Safe Working Load (SWL) |

|---|---|---|

| Definition | Maximum load a shipbuilding crane or equipment can carry as specified by the manufacturer. | Maximum load that can be safely lifted or supported during operations, factoring in safety margins. |

| Purpose | Defines technical capacity and design limits. | Ensures operational safety by limiting load below the rated capacity. |

| Application | Used for design and manufacturing specifications. | Used for daily operational limits and safety compliance. |

| Safety Margin | Usually no safety reduction applied. | Includes safety factor, typically 1.25 to 1.5 times less than rated load. |

| Regulatory Reference | Defined by equipment manufacturer standards. | Guided by maritime safety codes and shipbuilding regulations. |

| Relevance in Shipbuilding | Critical for crane and lifting equipment design. | Essential for operational safety and preventing accidents during lifting. |

Introduction to Rated Load and Safe Working Load

Rated load refers to the maximum load a machine or lifting equipment is designed to handle under specific conditions without risk of failure. Safe working load (SWL) is the maximum load that can be safely applied during normal operation after applying safety factors to the rated load. Your understanding of the distinction between rated load and SWL is crucial for ensuring operational safety and preventing equipment damage.

Defining Rated Load: What You Need to Know

Rated load refers to the maximum load a piece of equipment, such as a crane or hoist, is designed to safely handle under specific operating conditions. It accounts for factors like machine strength, design limits, and safety margins ensuring optimal performance without risk of failure. Differentiating rated load from safe working load is crucial, as the safe working load often includes additional safety factors for everyday usage limits.

Understanding Safe Working Load (SWL)

Safe Working Load (SWL) refers to the maximum load a lifting device or equipment can safely handle without risk of failure, determined by applying a safety factor to the Rated Load or Maximum Load Capacity. The SWL ensures operational safety by accounting for potential uncertainties in material strength, wear, and dynamic forces during lifting tasks. Understanding SWL is crucial for compliance with industry standards like ISO and OSHA to prevent accidents and equipment damage.

Key Differences Between Rated Load and Safe Working Load

Rated load represents the maximum capacity a lifting device or equipment is designed to handle under ideal conditions, reflecting its engineered limit. Safe Working Load (SWL) defines the maximum load that can be safely applied during regular operations, incorporating a safety factor to prevent overloading and equipment failure. The key difference lies in SWL accounting for operational safety margins, whereas rated load indicates technical maximum capacity without safety considerations.

Why Rated Load and SWL Matter in Lifting Operations

Rated Load and Safe Working Load (SWL) are critical measurements ensuring safety and efficiency in lifting operations by defining the maximum permissible weight equipment can handle without risk of failure. Understanding these limits protects your team and machinery from overloading hazards, preventing accidents and costly downtime. Accurate adherence to Rated Load and SWL safeguards structural integrity and optimizes operational performance in industrial environments.

Factors Influencing Rated Load and SWL Calculations

Rated load and Safe Working Load (SWL) are influenced by factors such as material strength, design safety factors, and operational conditions like temperature and load variability. Accurate calculations require consideration of dynamic forces, potential wear, and manufacturer specifications to ensure equipment reliability and safety. Understanding these elements helps you select appropriate load limits to prevent structural failure or accidents.

Risks of Exceeding Rated Load or SWL

Exceeding the rated load or safe working load (SWL) of lifting equipment significantly increases the risk of mechanical failure, leading to potential accidents, structural damage, and severe injuries. Overloading compromises the integrity of components like hooks, chains, and ropes, accelerating wear and increasing the likelihood of unexpected breakage. Adhering strictly to the rated load or SWL ensures operational safety and prolongs the lifespan of lifting machinery.

Industry Standards and Regulations for Load Ratings

Industry standards such as ASME B30.2 and ISO 4306 define rated load as the maximum load a lifting device can handle under ideal conditions, while the safe working load (SWL) incorporates safety factors to ensure operational safety. Regulations from OSHA and ANSI require manufacturers to clearly mark SWL to prevent overloading and accidents during material handling operations. Compliance with these standards ensures both equipment integrity and worker safety by accounting for dynamic forces and wear in load ratings.

Best Practices for Ensuring Load Safety

Rated load refers to the maximum load capacity specified by the manufacturer, while safe working load (SWL) incorporates a safety factor to account for dynamic forces and uncertainties during operation. Best practices for ensuring load safety include regularly inspecting lifting equipment, adhering strictly to SWL limits, and training personnel on load handling procedures. Implementing real-time monitoring systems and proper maintenance schedules further enhances safety and prevents equipment failure.

Conclusion: Choosing the Right Load Limit for Safety

Rated load represents the maximum capacity equipment can handle under ideal conditions, while the safe working load (SWL) includes a significant safety factor to prevent accidents. Selecting Your equipment based on the SWL ensures operational safety by accounting for dynamic forces and unexpected stresses during use. Prioritizing the safe working load over the rated load minimizes the risk of equipment failure and enhances workplace safety.

Rated load vs safe working load Infographic

libmatt.com

libmatt.com