Chemical tankers are specifically designed to transport hazardous and corrosive chemicals safely with specialized coatings and containment systems, while oil tankers primarily carry crude oil or petroleum products in large quantities with an emphasis on maximizing cargo volume. Your choice depends on the type of cargo being transported, with chemical tankers offering enhanced safety features for diverse chemical loads and oil tankers optimized for bulk hydrocarbon transport.

Table of Comparison

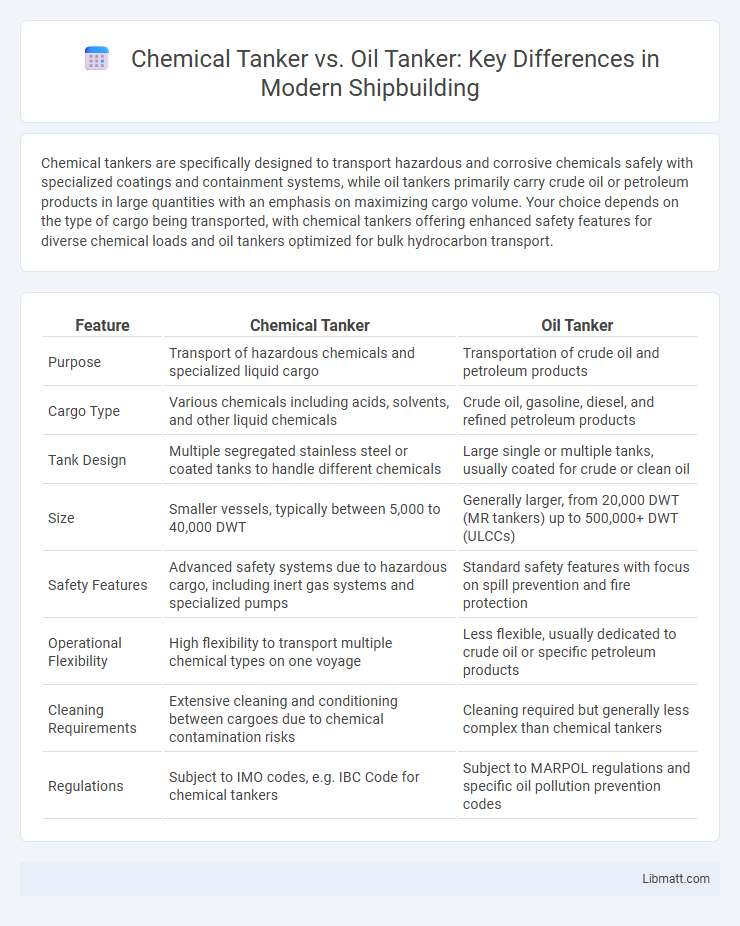

| Feature | Chemical Tanker | Oil Tanker |

|---|---|---|

| Purpose | Transport of hazardous chemicals and specialized liquid cargo | Transportation of crude oil and petroleum products |

| Cargo Type | Various chemicals including acids, solvents, and other liquid chemicals | Crude oil, gasoline, diesel, and refined petroleum products |

| Tank Design | Multiple segregated stainless steel or coated tanks to handle different chemicals | Large single or multiple tanks, usually coated for crude or clean oil |

| Size | Smaller vessels, typically between 5,000 to 40,000 DWT | Generally larger, from 20,000 DWT (MR tankers) up to 500,000+ DWT (ULCCs) |

| Safety Features | Advanced safety systems due to hazardous cargo, including inert gas systems and specialized pumps | Standard safety features with focus on spill prevention and fire protection |

| Operational Flexibility | High flexibility to transport multiple chemical types on one voyage | Less flexible, usually dedicated to crude oil or specific petroleum products |

| Cleaning Requirements | Extensive cleaning and conditioning between cargoes due to chemical contamination risks | Cleaning required but generally less complex than chemical tankers |

| Regulations | Subject to IMO codes, e.g. IBC Code for chemical tankers | Subject to MARPOL regulations and specific oil pollution prevention codes |

Overview of Chemical Tankers and Oil Tankers

Chemical tankers are specialized vessels designed to transport a wide range of liquid chemicals in bulk, equipped with complex heating, cooling, and cleaning systems to handle hazardous and reactive substances safely. Oil tankers mainly carry crude oil or refined petroleum products, featuring simpler tank structures optimized for large volume transport of non-corrosive liquids. Both types utilize double-hull designs to minimize environmental risks, but chemical tankers demand advanced compartmentalization and corrosion-resistant coatings for diverse cargo compatibility.

Key Differences in Cargo Types

Chemical tankers are specially designed to transport a wide range of hazardous and non-hazardous chemicals, including acids, alcohols, and other liquid chemicals that require segregated cargo tanks and advanced safety systems. Oil tankers primarily carry crude oil or refined petroleum products like gasoline, diesel, and jet fuel, focusing on large-volume bulk transport without the need for cargo segregation to the same extent as chemical tankers. The distinct cargo types necessitate unique structural features, tank coatings, and handling protocols to prevent contamination and ensure safety during transit.

Design and Construction Variations

Chemical tankers feature multiple segregated tanks made with stainless steel or coated carbon steel to handle diverse and corrosive cargoes safely, while oil tankers usually have fewer, larger tanks designed for bulk crude oil or refined products. Chemical tanker designs emphasize complex piping systems and advanced heating coils to manage various chemical properties and maintain cargo stability, contrasting with oil tankers' simpler pump and piping arrangements optimized for large volume transfer. Structural differences also include enhanced safety features and coatings in chemical tankers to prevent contamination and withstand toxic or reactive chemicals, which are less critical in conventional oil tanker construction.

Cargo Handling and Safety Systems

Chemical tankers feature advanced cargo handling systems designed for multiple hazardous and corrosive substances, equipped with specialized coatings and heating capabilities to maintain chemical stability. Oil tankers prioritize bulk oil transfer with robust inert gas systems and emergency shutdown mechanisms to prevent explosions and spills. Your choice should consider the compatibility of cargo handling infrastructure and integrated safety systems to ensure secure and efficient operations.

Regulatory Framework and Compliance

Chemical tankers operate under the International Maritime Organization's (IMO) International Bulk Chemical Code (IBC Code), ensuring strict compliance with safety and environmental regulations for transporting hazardous chemicals. Oil tankers are governed by the IMO's International Convention for the Prevention of Pollution from Ships (MARPOL), particularly Annex I, which addresses oil pollution prevention measures. Both types of tankers must adhere to specific crew training, vessel construction standards, and emergency response protocols tailored to their cargo's risk profiles.

Crew Training and Operational Procedures

Chemical tankers demand highly specialized crew training focused on handling diverse hazardous cargoes, including stringent safety protocols and emergency response measures. Oil tanker crews require expertise in managing large volumes of crude or refined oil, emphasizing spill prevention and environmental protection procedures. Your choice between these vessels should consider the complexity of training and operational standards necessary for safe and efficient cargo management.

Environmental Considerations

Chemical tankers are designed with advanced containment systems and corrosion-resistant materials to minimize the risk of hazardous spills, making them more suitable for transporting diverse and potentially harmful chemicals safely. Oil tankers, while equipped with double hulls and other safety features, carry large volumes of crude oil or petroleum products that pose a higher environmental risk in case of spills, often resulting in severe marine pollution and long-term ecosystem damage. Your choice between these vessels can significantly impact environmental safety, especially in sensitive marine areas requiring stringent spill prevention measures.

Market Demand and Trade Routes

Chemical tankers experience rising market demand due to increasing global trade in specialty chemicals and strict environmental regulations requiring segregated cargoes, primarily serving short to medium-haul trade routes in regions like Asia-Pacific and Europe. Oil tankers maintain high market demand driven by the continuous global consumption of crude oil and refined petroleum products, predominantly operating on long-haul routes between oil-exporting countries in the Middle East, West Africa, and Latin America to major importing regions such as North America, Europe, and Asia. Trade route selection for chemical tankers focuses on ports equipped with advanced handling facilities for hazardous substances, while oil tankers prioritize large-scale terminals capable of accommodating massive volumes and ensuring efficient loading and unloading processes.

Risk Factors and Accident History

Chemical tankers face higher risk factors due to the diverse and often hazardous nature of their cargo, including corrosive and toxic substances, which demand specialized handling and containment systems. Oil tankers have a long history of large-scale accidents primarily involving oil spills, resulting in severe environmental damage and costly cleanup efforts, with incidents like the Exxon Valdez and Deepwater Horizon highlighting their vulnerability. Understanding these distinct risk profiles helps you assess safety measures and regulatory compliance critical for minimizing accidents in both vessel types.

Future Trends in Tanker Shipping

Future trends in tanker shipping emphasize increased adoption of eco-friendly technologies such as LNG propulsion and advanced hull coatings to reduce emissions in both chemical and oil tankers. The chemical tanker sector is trending towards more specialized vessels with enhanced safety systems for transporting diverse and hazardous chemicals. Digitalization, including real-time monitoring and AI-driven logistics, is set to optimize operational efficiency and regulatory compliance across the tanker shipping industry.

Chemical tanker vs oil tanker Infographic

libmatt.com

libmatt.com