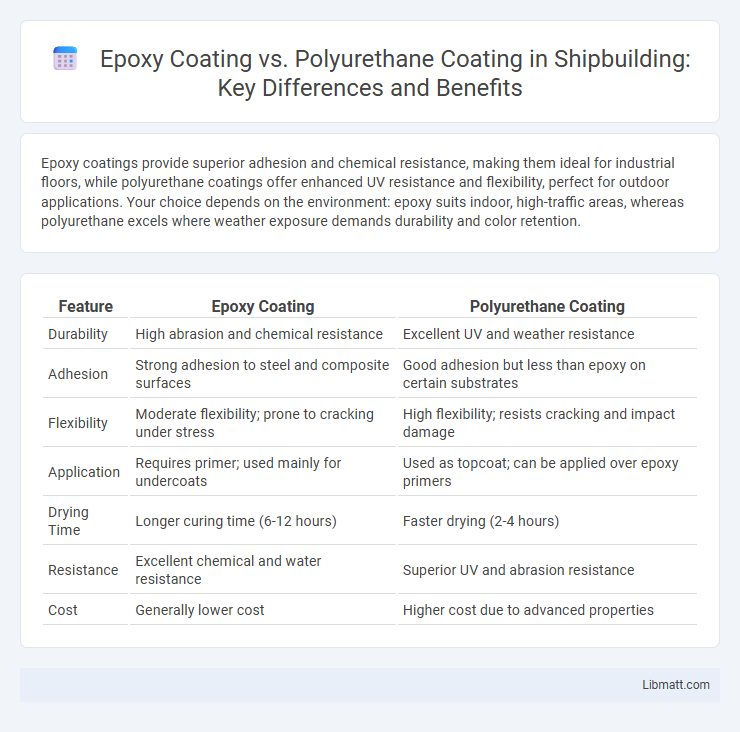

Epoxy coatings provide superior adhesion and chemical resistance, making them ideal for industrial floors, while polyurethane coatings offer enhanced UV resistance and flexibility, perfect for outdoor applications. Your choice depends on the environment: epoxy suits indoor, high-traffic areas, whereas polyurethane excels where weather exposure demands durability and color retention.

Table of Comparison

| Feature | Epoxy Coating | Polyurethane Coating |

|---|---|---|

| Durability | High abrasion and chemical resistance | Excellent UV and weather resistance |

| Adhesion | Strong adhesion to steel and composite surfaces | Good adhesion but less than epoxy on certain substrates |

| Flexibility | Moderate flexibility; prone to cracking under stress | High flexibility; resists cracking and impact damage |

| Application | Requires primer; used mainly for undercoats | Used as topcoat; can be applied over epoxy primers |

| Drying Time | Longer curing time (6-12 hours) | Faster drying (2-4 hours) |

| Resistance | Excellent chemical and water resistance | Superior UV and abrasion resistance |

| Cost | Generally lower cost | Higher cost due to advanced properties |

Introduction to Epoxy and Polyurethane Coatings

Epoxy coatings provide exceptional chemical resistance and adhesion, making them ideal for industrial floors and protective surfaces. Polyurethane coatings offer superior flexibility, UV stability, and abrasion resistance, suited for exterior applications exposed to harsh weather conditions. Choosing between epoxy and polyurethane coatings depends on your specific requirements for durability, appearance, and environmental exposure.

Key Differences Between Epoxy and Polyurethane Coatings

Epoxy coatings provide superior adhesion and chemical resistance, making them ideal for industrial flooring and surfaces exposed to heavy wear. Polyurethane coatings offer enhanced UV resistance and flexibility, which helps prevent cracking and discoloration in outdoor or high-traffic environments. Durability and application conditions differ, with epoxy curing faster but polyurethane offering better resistance to weathering and abrasion.

Chemical Composition and Properties

Epoxy coatings consist of epoxy resins and hardeners that form a highly durable, chemical-resistant thermoset polymer, offering excellent adhesion and mechanical strength. Polyurethane coatings are composed of polyol and isocyanate compounds, providing superior flexibility, UV resistance, and abrasion resistance compared to epoxy. Your choice depends on the environment, as epoxy excels in chemical resistance while polyurethane offers better weathering and impact tolerance.

Durability and Performance Comparison

Epoxy coatings offer exceptional chemical resistance and strong adhesion, making them ideal for heavy-duty industrial floors subjected to high abrasion and impact. Polyurethane coatings provide superior UV resistance and flexibility, maintaining durability in outdoor environments exposed to sunlight and temperature fluctuations. Both coatings perform well in durability, but epoxy excels in hardness and chemical resistance, while polyurethane outperforms in weather resistance and elasticity.

Application Areas and Suitability

Epoxy coatings excel in industrial environments such as warehouses and manufacturing plants due to their superior chemical resistance and adhesion on concrete floors. Polyurethane coatings are more suitable for areas exposed to UV radiation and frequent abrasion, like outdoor surfaces and commercial spaces, because of their flexibility and UV stability. Both coatings serve diverse application areas, with epoxy preferred for heavy-duty indoor protection and polyurethane chosen for outdoor durability and aesthetic finish.

Surface Preparation Requirements

Epoxy coatings require meticulous surface preparation, including thorough cleaning, degreasing, and abrasive blasting to achieve optimal adhesion and durability. Polyurethane coatings demand a clean, dry surface but are generally more forgiving with minor surface imperfections due to their flexibility. Your choice of coating should consider these differences to ensure the longevity and performance of the protective finish.

Resistance to Chemicals and Abrasion

Epoxy coating offers superior resistance to chemicals such as solvents, acids, and alkalis, making it ideal for industrial environments with high exposure to corrosive substances. Polyurethane coating excels in abrasion resistance due to its flexible and elastic properties, providing excellent durability under mechanical wear and impact. Both coatings provide robust protection, but epoxy is preferred for chemical-heavy applications while polyurethane is better suited for surfaces subjected to constant friction and physical stress.

Cost Considerations and Economic Factors

Epoxy coating typically offers a lower initial cost compared to polyurethane coating, making it a budget-friendly option for many projects. However, polyurethane coatings provide superior flexibility and UV resistance, which can reduce long-term maintenance expenses and increase overall cost-effectiveness. Carefully evaluating your project's lifespan and environmental exposure helps determine which coating delivers the best economic value.

Maintenance and Longevity

Epoxy coating offers excellent durability and resistance to abrasion, making it ideal for high-traffic areas that require low maintenance over time. Polyurethane coating provides superior UV resistance and flexibility, which helps prevent cracking and discoloration, ensuring longer-lasting protection in outdoor environments. Choosing the right coating for your surfaces depends on whether you prioritize quick maintenance or extended longevity under varying conditions.

Choosing the Right Coating: Epoxy vs Polyurethane

Epoxy coatings offer superior chemical resistance and durability, making them ideal for industrial floors and high-traffic areas, while polyurethane coatings provide excellent UV resistance and flexibility, suitable for exterior surfaces exposed to sunlight. Your decision should consider the specific environment and performance needs, as epoxy is better for heavy-duty applications and polyurethane excels in weather-resistant finishes. Evaluating factors like abrasion resistance, curing time, and finish quality ensures you select the right coating for long-lasting protection and aesthetic appeal.

Epoxy coating vs polyurethane coating Infographic

libmatt.com

libmatt.com