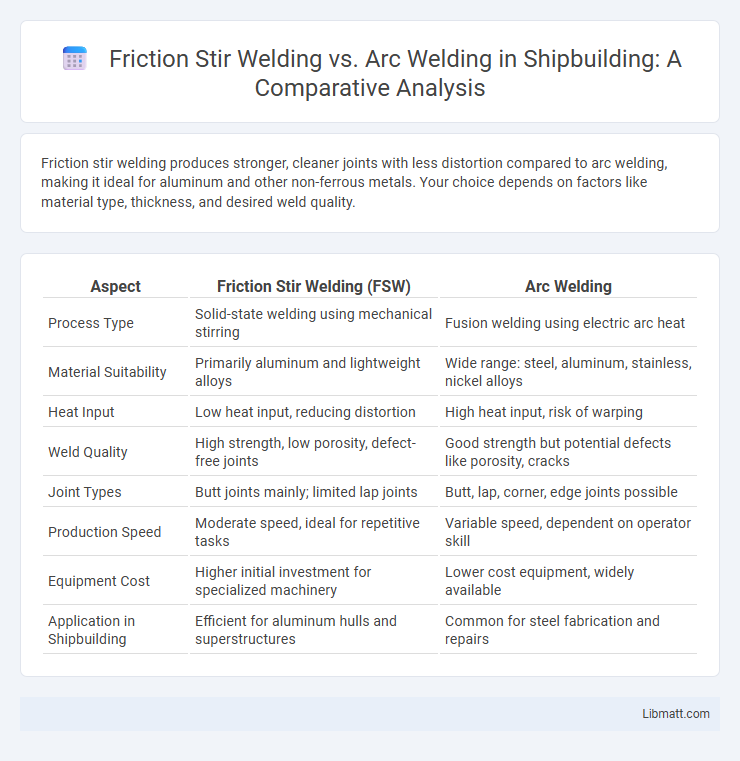

Friction stir welding produces stronger, cleaner joints with less distortion compared to arc welding, making it ideal for aluminum and other non-ferrous metals. Your choice depends on factors like material type, thickness, and desired weld quality.

Table of Comparison

| Aspect | Friction Stir Welding (FSW) | Arc Welding |

|---|---|---|

| Process Type | Solid-state welding using mechanical stirring | Fusion welding using electric arc heat |

| Material Suitability | Primarily aluminum and lightweight alloys | Wide range: steel, aluminum, stainless, nickel alloys |

| Heat Input | Low heat input, reducing distortion | High heat input, risk of warping |

| Weld Quality | High strength, low porosity, defect-free joints | Good strength but potential defects like porosity, cracks |

| Joint Types | Butt joints mainly; limited lap joints | Butt, lap, corner, edge joints possible |

| Production Speed | Moderate speed, ideal for repetitive tasks | Variable speed, dependent on operator skill |

| Equipment Cost | Higher initial investment for specialized machinery | Lower cost equipment, widely available |

| Application in Shipbuilding | Efficient for aluminum hulls and superstructures | Common for steel fabrication and repairs |

Introduction to Friction Stir Welding and Arc Welding

Friction stir welding (FSW) is a solid-state joining process that uses a rotating tool to generate frictional heat, plasticizing materials without melting, resulting in superior mechanical properties and minimal distortion. Arc welding relies on an electric arc to melt and fuse metals, commonly used for its versatility in joining various metals and thicknesses. FSW offers enhanced joint strength and reduced defects compared to traditional arc welding methods, making it ideal for aerospace and automotive applications.

Process Overview: Friction Stir Welding

Friction Stir Welding (FSW) is a solid-state joining process where a rotating tool generates frictional heat to soften and stir the materials along the joint line without melting them. This technique produces high-strength welds with minimal distortion and eliminates common melting-related defects seen in arc welding. FSW is especially effective for joining aluminum alloys, enhancing mechanical properties through fine-grain microstructures.

Process Overview: Arc Welding

Arc welding utilizes an electric arc to generate intense heat, melting the base metals and filler material to create a strong joint upon cooling. This process involves consumable or non-consumable electrodes, shield gases, and requires skilled control of current and voltage for optimal weld quality. Common arc welding techniques include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW), each suitable for different materials and fabrication requirements.

Key Differences Between Friction Stir and Arc Welding

Friction stir welding (FSW) uses a rotating tool to join metals in the solid state, producing minimal distortion and high-strength joints, while arc welding relies on an electric arc to melt and fuse metals, often leading to higher heat input and potential warping. FSW is particularly effective for aluminum and other non-ferrous alloys, offering superior weld quality without filler materials, whereas arc welding suits a broader range of metals but may require additional consumables like electrodes or shielding gas. In terms of environmental impact, FSW generates less smoke and spatter, contributing to a cleaner work environment compared to the emissions common in arc welding processes.

Material Compatibility and Applications

Friction stir welding excels with non-ferrous metals like aluminum, magnesium, and copper, providing superior joint strength without melting the base material, making it ideal for aerospace and automotive industries. Arc welding suits a broader range of materials, including steels, stainless steel, and cast iron, offering versatile application in construction, shipbuilding, and heavy equipment manufacturing. Your choice depends on material type and performance requirements, with friction stir welding preferred for lightweight alloys and arc welding for thicker, ferrous metals.

Strength and Quality of Weld Joints

Friction stir welding produces weld joints with superior strength and consistency due to its solid-state process, which eliminates defects like porosity and cracking commonly found in arc welding. Arc welding often results in welds with variable quality and lower fatigue resistance because of molten metal solidification and potential contamination. Your projects benefit from friction stir welding's enhanced joint integrity, especially in critical applications requiring high durability.

Efficiency and Production Speed

Friction stir welding (FSW) offers higher efficiency and faster production speed compared to arc welding, as it eliminates the need for filler materials and reduces post-weld finishing. FSW produces consistent, high-quality welds with minimal distortion, enabling quicker assembly in manufacturing processes such as aerospace and automotive industries. Your production line can benefit from decreased welding times and lower energy consumption with friction stir welding technology.

Environmental Impact and Safety Considerations

Friction stir welding (FSW) significantly reduces environmental impact by producing minimal fumes, lower energy consumption, and virtually no hazardous emissions compared to traditional arc welding processes, which generate harmful gases and higher energy use. Safety considerations favor FSW due to the absence of open flames or electric arcs, reducing risks of burns, UV radiation exposure, and toxic inhalants commonly associated with arc welding. These advantages make FSW a cleaner, safer option for industries aiming to minimize occupational hazards and environmental footprint.

Cost Analysis: Friction Stir vs Arc Welding

Friction stir welding (FSW) offers lower long-term operational costs compared to arc welding due to reduced energy consumption and minimal consumable materials. While initial equipment investment for FSW can be higher, the process decreases rework and defects, leading to enhanced productivity and cost savings. Your choice should balance upfront expenses with maintenance efficiency and material utilization to optimize overall welding costs.

Choosing the Right Welding Technique

Friction stir welding offers superior joint strength and minimal distortion for aluminum and non-ferrous metals, making it ideal for aerospace and automotive applications requiring precision. Arc welding provides versatility across various metals and thicknesses, suitable for general fabrication and repair tasks where equipment portability is essential. Your choice depends on material type, desired weld quality, and production scale, with friction stir welding excelling in high-performance environments and arc welding favored for accessibility and cost-effectiveness.

Friction stir welding vs arc welding Infographic

libmatt.com

libmatt.com