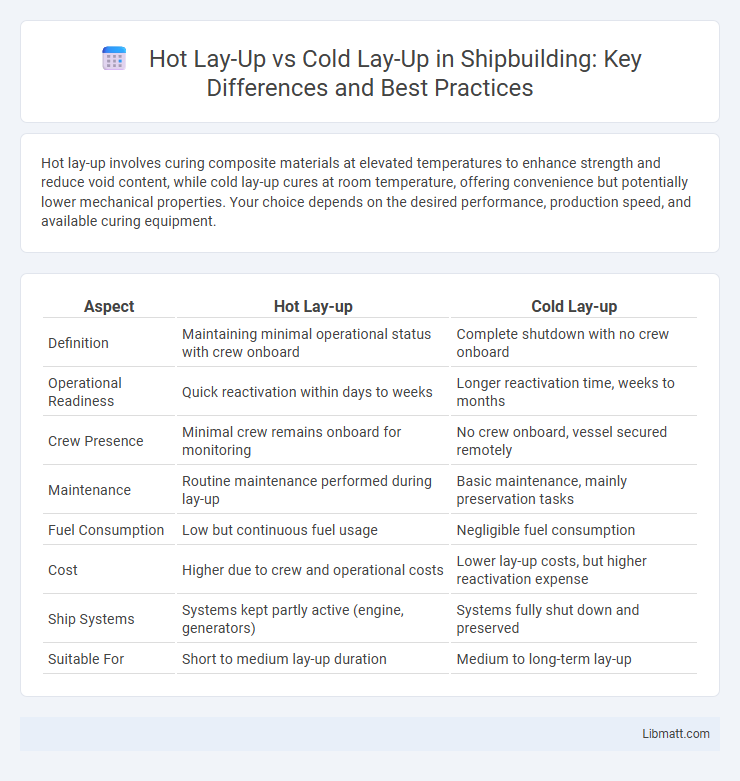

Hot lay-up involves curing composite materials at elevated temperatures to enhance strength and reduce void content, while cold lay-up cures at room temperature, offering convenience but potentially lower mechanical properties. Your choice depends on the desired performance, production speed, and available curing equipment.

Table of Comparison

| Aspect | Hot Lay-up | Cold Lay-up |

|---|---|---|

| Definition | Maintaining minimal operational status with crew onboard | Complete shutdown with no crew onboard |

| Operational Readiness | Quick reactivation within days to weeks | Longer reactivation time, weeks to months |

| Crew Presence | Minimal crew remains onboard for monitoring | No crew onboard, vessel secured remotely |

| Maintenance | Routine maintenance performed during lay-up | Basic maintenance, mainly preservation tasks |

| Fuel Consumption | Low but continuous fuel usage | Negligible fuel consumption |

| Cost | Higher due to crew and operational costs | Lower lay-up costs, but higher reactivation expense |

| Ship Systems | Systems kept partly active (engine, generators) | Systems fully shut down and preserved |

| Suitable For | Short to medium lay-up duration | Medium to long-term lay-up |

Introduction to Marine Lay-Up Methods

Marine lay-up methods are essential for preserving vessels during periods of inactivity, with hot lay-up and cold lay-up representing two primary techniques. Hot lay-up involves maintaining essential machinery and systems in operational condition to allow for quick reactivation, typically used for short-term downtime. Cold lay-up entails shutting down most systems and draining fluids to minimize maintenance costs and extend preservation during longer periods of inactivity.

Defining Hot Lay-Up

Hot lay-up is a ship preservation method where the vessel's machinery remains heated and ready for quick activation, ensuring rapid restart and minimal downtime. This technique involves keeping boilers, turbines, and auxiliary systems at operational temperatures, which prevents corrosion and moisture buildup. Your choice of hot lay-up optimizes efficiency when a prompt return to service is essential.

Understanding Cold Lay-Up

Cold lay-up is a preservation method for vessels where equipment is thoroughly cleaned, drained, and coated with rust inhibitors to prevent corrosion during extended inactivity. This technique saves energy by shutting down all heating and ventilation systems, maintaining a low temperature environment while controlling humidity. Unlike hot lay-up, cold lay-up requires more frequent inspections and dehumidification to protect critical machinery and structural integrity.

Key Differences: Hot Lay-Up vs Cold Lay-Up

Hot lay-up involves maintaining elevated temperature levels on machinery or equipment during shutdown periods to prevent condensation and corrosion, whereas cold lay-up allows equipment to cool naturally, often requiring more extensive preservation measures. Hot lay-up typically demands continuous insulation and heating systems, ensuring faster restart times and reduced maintenance costs, while cold lay-up minimizes energy consumption but may increase the risk of moisture-related damage and longer recommissioning processes. The choice between hot and cold lay-up depends on factors such as equipment type, shutdown duration, and environmental conditions impacting corrosion control and operational efficiency.

Advantages of Hot Lay-Up

Hot lay-up offers significant advantages such as maintaining optimal temperature to prevent corrosion and microbial growth within pipelines or equipment during downtime. This method ensures rapid and effective preservation, reducing the risk of damage and costly repairs. Moreover, hot lay-up facilitates quicker reactivation compared to cold lay-up, minimizing operational downtime.

Benefits of Cold Lay-Up

Cold lay-up offers significant benefits including reduced maintenance costs and extended equipment lifespan by minimizing operational stress during downtime. Your machinery remains protected from corrosion and deterioration without the need for continuous heating, making it an energy-efficient and cost-effective solution. This method is particularly advantageous for long-term storage or inactive periods in industries such as power generation and manufacturing.

Cost Comparison: Hot Lay-Up vs Cold Lay-Up

Hot lay-up involves higher initial costs due to the use of heating equipment and energy consumption, whereas cold lay-up requires less immediate expenditure since it relies on natural cooling and minimal equipment. Your choice impacts long-term operational expenses, as hot lay-up can reduce corrosion risks and maintenance costs, while cold lay-up may lead to increased repair expenses due to slower drying and potential microbial growth. Evaluating both methods' cost-effectiveness depends on vessel downtime duration and environmental factors influencing preservation needs.

Maintenance Requirements for Each Method

Hot lay-up requires continuous heating and monitoring to maintain optimal temperature, preventing corrosion but demanding higher energy consumption and frequent inspections. Cold lay-up involves sealing and dehumidifying the system without active heating, reducing operational costs but necessitating thorough moisture control and periodic checks to avoid corrosion risks. Both methods require tailored maintenance protocols to ensure system integrity during inactivity, with hot lay-up focusing on temperature stability and cold lay-up emphasizing moisture management.

Factors Influencing Lay-Up Decisions

Factors influencing lay-up decisions include the vessel's maintenance schedule, environmental conditions, and expected downtime duration. Hot lay-up requires continuous power to maintain systems and prevent corrosion, making it ideal for short-term out-of-service periods with quick reactivation needs. Your choice depends on balancing operational costs, preservation needs, and the timeline for returning the vessel to active duty.

Choosing the Right Lay-Up Strategy for Your Vessel

Choosing the right lay-up strategy for your vessel depends on factors such as expected lay-up duration, environmental conditions, and maintenance resources. Hot lay-up maintains vessel systems in operational readiness with continuous power, ideal for short to medium-term inactivity, while cold lay-up involves shutting down most systems to reduce costs during long-term idling. Evaluating operational costs, crew requirements, and vessel preservation needs helps optimize the lay-up method to ensure safety, minimize corrosion, and enable quicker reactivation.

Hot lay-up vs cold lay-up Infographic

libmatt.com

libmatt.com