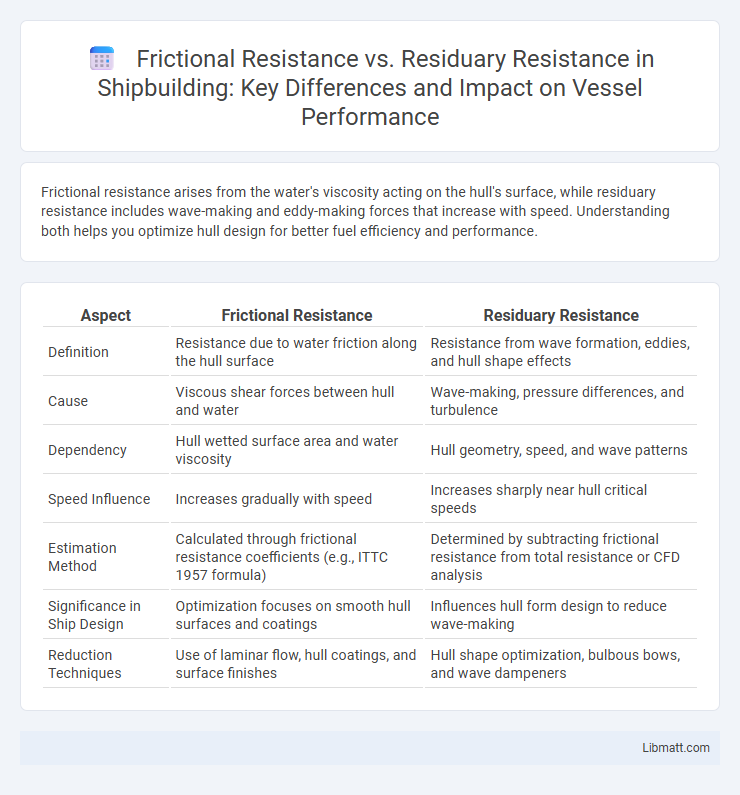

Frictional resistance arises from the water's viscosity acting on the hull's surface, while residuary resistance includes wave-making and eddy-making forces that increase with speed. Understanding both helps you optimize hull design for better fuel efficiency and performance.

Table of Comparison

| Aspect | Frictional Resistance | Residuary Resistance |

|---|---|---|

| Definition | Resistance due to water friction along the hull surface | Resistance from wave formation, eddies, and hull shape effects |

| Cause | Viscous shear forces between hull and water | Wave-making, pressure differences, and turbulence |

| Dependency | Hull wetted surface area and water viscosity | Hull geometry, speed, and wave patterns |

| Speed Influence | Increases gradually with speed | Increases sharply near hull critical speeds |

| Estimation Method | Calculated through frictional resistance coefficients (e.g., ITTC 1957 formula) | Determined by subtracting frictional resistance from total resistance or CFD analysis |

| Significance in Ship Design | Optimization focuses on smooth hull surfaces and coatings | Influences hull form design to reduce wave-making |

| Reduction Techniques | Use of laminar flow, hull coatings, and surface finishes | Hull shape optimization, bulbous bows, and wave dampeners |

Introduction to Ship Resistance

Ship resistance consists mainly of frictional resistance and residuary resistance, which together determine the total force opposing a vessel's motion through water. Frictional resistance arises from the viscous drag of water along the ship's wetted surface area, influenced by hull roughness and velocity. Residuary resistance includes wave-making resistance, eddy formation, and other hydrodynamic effects related to hull shape and flow separation.

Defining Frictional Resistance

Frictional resistance is the component of total ship resistance caused by the viscosity of water acting on the wetted surface area of the hull. It arises from the shear forces between the water and the ship's hull, resulting in energy loss as the vessel moves through the fluid. In contrast, residuary resistance includes wave-making and eddy resistance, which are separate phenomena related to the ship's shape and motion.

Understanding Residuary Resistance

Residuary resistance refers to the component of a vessel's total resistance excluding frictional resistance, primarily comprising wave-making resistance and eddy-making resistance. It arises due to the pressure distribution around the hull and the energy lost in creating waves and turbulent flow in the water. Understanding residuary resistance is essential for optimizing hull design to reduce energy consumption and improve the vessel's overall hydrodynamic efficiency.

Key Differences Between Frictional and Residuary Resistance

Frictional resistance primarily arises from the viscous shear stresses acting on the wetted surface of a ship's hull, directly related to the hull's surface roughness and water viscosity. Residuary resistance, on the other hand, encompasses wave-making resistance, eddy formation, and other form-related effects that do not involve viscous shear but result from the ship's shape and speed. Understanding the distinction between these resistances is crucial for optimizing hull design to minimize total resistance and improve fuel efficiency.

Factors Affecting Frictional Resistance

Frictional resistance in ship hydrodynamics is primarily influenced by water viscosity, surface roughness, and hull wetted surface area, which increase drag as water flows along the vessel's hull. Temperature and salinity variations alter water density and viscosity, thereby impacting the magnitude of frictional resistance experienced during navigation. Unlike residuary resistance, which includes wave-making and eddy resistance, frictional resistance is more directly tied to physical properties of the water and the hull's surface condition.

Factors Influencing Residuary Resistance

Residuary resistance is influenced by factors such as hull shape, wave-making effects, and flow separation around the vessel. Unlike frictional resistance, which depends primarily on the water's viscosity and the wetted surface area, residuary resistance varies with speed, hull form complexity, and the formation of vortices or turbulent wakes. Understanding these elements is crucial for optimizing ship design to minimize energy loss and enhance fuel efficiency.

Methods to Measure Frictional and Residuary Resistance

Frictional resistance is typically measured using towing tank tests with smooth model hulls to isolate viscous effects, employing methods like the ITTC-1957 friction line formula based on Reynolds numbers. Residuary resistance, which includes wave-making and form resistance, is assessed through model testing combined with extrapolation techniques such as the slender body theory or the use of computational fluid dynamics (CFD) simulations to capture pressure distribution and wave patterns. Both resistances are often separated by comparing total resistance measurements at different speeds and subtracting the calculated frictional resistance from the overall resistance data.

Impact on Ship Performance and Fuel Efficiency

Frictional resistance, caused by water viscosity along the ship's hull, significantly increases fuel consumption as it directly impacts the energy required to maintain speed. Residuary resistance, comprising wave-making and eddy resistance, influences ship performance by affecting stability and speed, often requiring hull design optimization to minimize its effects. Understanding the balance between these resistances allows you to enhance your vessel's fuel efficiency and operational effectiveness.

Strategies to Minimize Resistance Components

Minimizing frictional resistance involves enhancing hull smoothness through advanced coatings like silicone or fluoropolymer-based paints, and regular hull cleaning to prevent biofouling. Reducing residuary resistance relies on optimizing hull form via computational fluid dynamics (CFD) to streamline bow and stern shapes, and incorporating bulbous bows to minimize wave generation. Employing air lubrication systems and designing slender hulls further decrease total resistance by targeting both frictional and residuary components efficiently.

Summary and Future Trends in Ship Resistance Research

Frictional resistance, caused by viscous shear forces along the hull, dominates the total ship resistance at lower speeds, while residuary resistance, including wave and pressure resistance, becomes significant at higher speeds and complex hull forms. Current research aims to refine predictive models using computational fluid dynamics (CFD) and experimental methods to better isolate and quantify these resistance components. Future trends emphasize integrating advanced machine learning algorithms and extensive hydrodynamic databases to optimize hull designs for reduced frictional and residuary resistances, enhancing fuel efficiency and environmental sustainability in maritime transport.

Frictional resistance vs residuary resistance Infographic

libmatt.com

libmatt.com