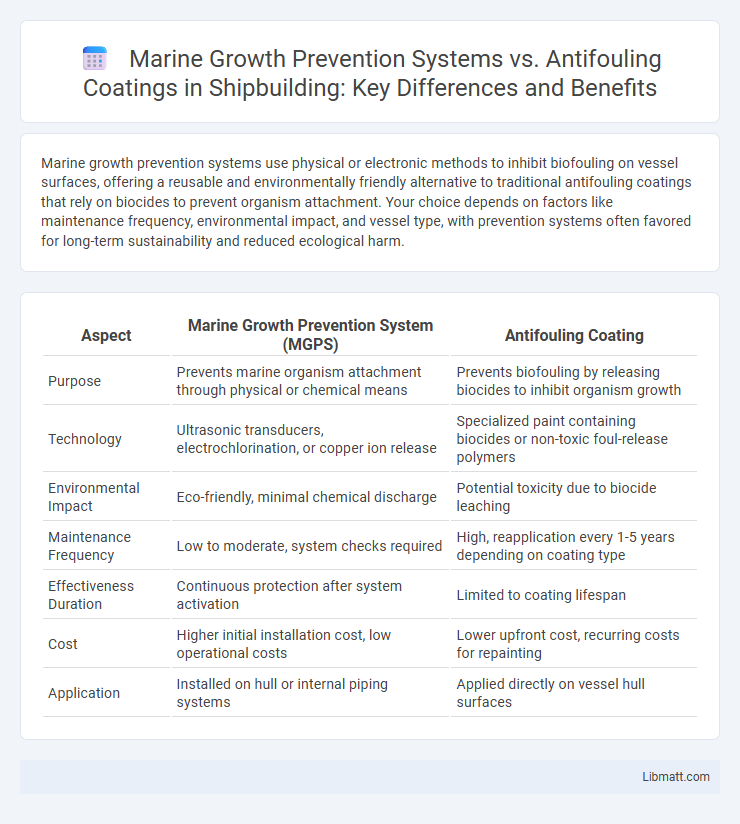

Marine growth prevention systems use physical or electronic methods to inhibit biofouling on vessel surfaces, offering a reusable and environmentally friendly alternative to traditional antifouling coatings that rely on biocides to prevent organism attachment. Your choice depends on factors like maintenance frequency, environmental impact, and vessel type, with prevention systems often favored for long-term sustainability and reduced ecological harm.

Table of Comparison

| Aspect | Marine Growth Prevention System (MGPS) | Antifouling Coating |

|---|---|---|

| Purpose | Prevents marine organism attachment through physical or chemical means | Prevents biofouling by releasing biocides to inhibit organism growth |

| Technology | Ultrasonic transducers, electrochlorination, or copper ion release | Specialized paint containing biocides or non-toxic foul-release polymers |

| Environmental Impact | Eco-friendly, minimal chemical discharge | Potential toxicity due to biocide leaching |

| Maintenance Frequency | Low to moderate, system checks required | High, reapplication every 1-5 years depending on coating type |

| Effectiveness Duration | Continuous protection after system activation | Limited to coating lifespan |

| Cost | Higher initial installation cost, low operational costs | Lower upfront cost, recurring costs for repainting |

| Application | Installed on hull or internal piping systems | Applied directly on vessel hull surfaces |

Introduction to Marine Fouling Challenges

Marine fouling poses significant challenges to vessel performance, increasing drag and fuel consumption while accelerating corrosion. Marine growth prevention systems (MGPS) use physical or chemical methods such as ultrasonic waves or biocides to inhibit organism attachment, offering a proactive approach to fouling control. Antifouling coatings rely on specialized paints embedded with biocides or non-toxic foul-release compounds to create surfaces that prevent marine organisms from adhering, reducing maintenance and operational costs.

Overview of Marine Growth Prevention Systems (MGPS)

Marine Growth Prevention Systems (MGPS) utilize electrochlorination or copper ion release to inhibit biofouling and prevent the accumulation of marine organisms on underwater structures. These systems offer an environmentally friendly alternative to traditional antifouling coatings by minimizing toxic chemical usage and providing continuous, maintenance-free protection. MGPS effectively reduce drag, maintain operational efficiency, and extend the lifespan of marine vessels and infrastructure.

Fundamentals of Antifouling Coatings

Antifouling coatings function by releasing biocides or creating non-stick surfaces that prevent marine organisms from adhering to submerged structures, reducing drag and corrosion. These coatings rely on chemical or physical mechanisms to inhibit biofouling growth, which is essential for maintaining vessel performance and fuel efficiency. Marine growth prevention systems differ by often employing physical barriers or cleaning technologies, rather than chemically active surfaces characteristic of antifouling coatings.

Key Differences Between MGPS and Antifouling Coating

Marine growth prevention systems (MGPS) use physical or chemical methods such as ultraviolet light or low-voltage electric fields to inhibit biofouling, whereas antifouling coatings rely on biocidal paints that release toxins to prevent organism attachment. MGPS provide non-toxic, environmentally friendly solutions with lower maintenance needs, while antifouling coatings require regular reapplication and may pose ecological risks. The effectiveness of MGPS is often limited to specific installations like seawater intakes, whereas antifouling coatings are widely used on ship hulls to enhance fuel efficiency and reduce drag.

Effectiveness in Protecting Marine Structures

Marine growth prevention systems utilize advanced biocides and ultrasonic technology to inhibit biofilm formation and marine organism attachment, offering continuous protection for submerged structures. Antifouling coatings rely on specialized paints embedded with biocides that slowly release toxins, creating a toxic surface deterring fouling species but may degrade over time under harsh marine conditions. The integration of marine growth prevention systems typically results in more durable, long-lasting protection compared to traditional antifouling coatings, reducing maintenance frequency and preserving structural integrity.

Environmental Impact and Sustainability

Marine growth prevention systems (MGPS) reduce biofouling using non-toxic methods such as ultrasonic waves or low-voltage electrical currents, significantly minimizing harmful chemical discharges into marine ecosystems. Antifouling coatings often contain biocides like copper or other heavy metals, which can accumulate in the environment, causing toxicity to marine life and long-term ecological damage. You can enhance your vessel's sustainability by choosing MGPS, which offer environmentally friendly and efficient biofouling control without compromising ocean health.

Maintenance Requirements and Longevity

Marine growth prevention systems offer lower maintenance requirements compared to traditional antifouling coatings, as they actively prevent organism attachment through methods like ultrasonic waves or electric fields. Antifouling coatings need frequent reapplication, often every 1 to 3 years, to remain effective against barnacles, algae, and other marine fouling. Your choice affects operational costs and vessel longevity, with prevention systems providing longer-lasting protection but typically involving higher upfront investment.

Cost Analysis: MGPS vs Antifouling Coatings

Marine Growth Prevention Systems (MGPS) typically involve higher upfront installation and equipment costs compared to antifouling coatings, which require periodic application but have lower initial expenses. Over time, MGPS can result in reduced maintenance and operational costs due to continuous protection and elimination of frequent dry-docking, whereas antifouling coatings necessitate recurring application and associated labor costs. Lifecycle cost analysis often favors MGPS for large commercial vessels due to savings in fuel efficiency and extended maintenance intervals despite higher initial investments.

Suitability for Different Marine Applications

Marine growth prevention systems (MGPS) are highly effective for industrial structures like offshore oil rigs, seawater intake pipes, and power plant cooling systems where continuous operation and minimal maintenance are critical. Antifouling coatings are better suited for ship hulls, smaller vessels, and recreational boats, providing a protective barrier that reduces biofouling and enhances fuel efficiency. MGPS offers targeted electrochemical or physical deterrence, making it ideal for static infrastructure, while antifouling coatings rely on biocidal or non-toxic surface treatments optimized for aquatic mobility.

Future Trends in Marine Anti-Fouling Technologies

Emerging trends in marine anti-fouling technologies emphasize eco-friendly marine growth prevention systems (MGPS) that reduce environmental impact compared to traditional antifouling coatings with toxic biocides. Advancements in smart coatings and ultrasonic MGPS offer real-time prevention of biofouling, effectively enhancing vessel efficiency and fuel savings. Your choice of innovative solutions will increasingly depend on integrating sustainable practices and regulatory compliance for future-proof marine operations.

Marine growth prevention system vs antifouling coating Infographic

libmatt.com

libmatt.com