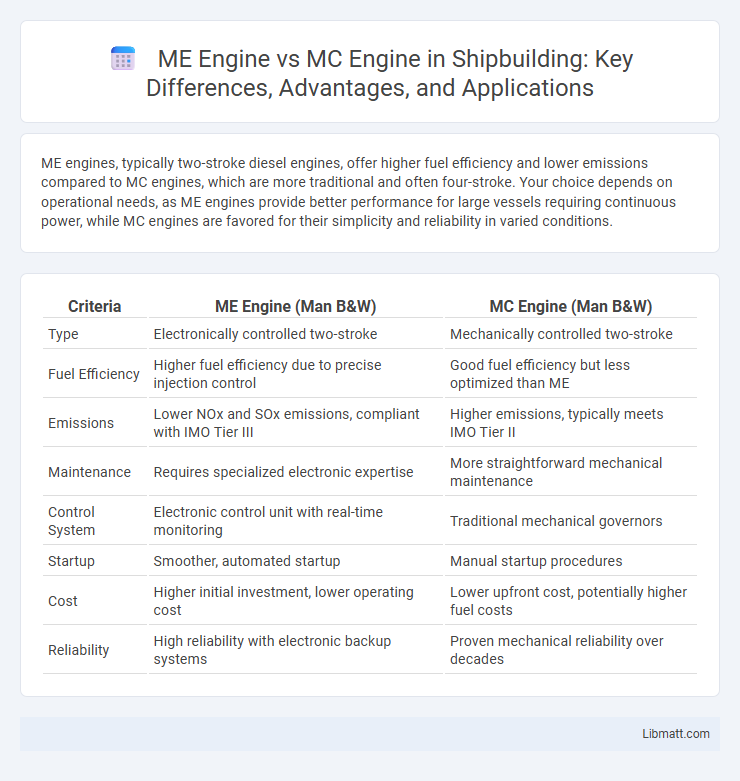

ME engines, typically two-stroke diesel engines, offer higher fuel efficiency and lower emissions compared to MC engines, which are more traditional and often four-stroke. Your choice depends on operational needs, as ME engines provide better performance for large vessels requiring continuous power, while MC engines are favored for their simplicity and reliability in varied conditions.

Table of Comparison

| Criteria | ME Engine (Man B&W) | MC Engine (Man B&W) |

|---|---|---|

| Type | Electronically controlled two-stroke | Mechanically controlled two-stroke |

| Fuel Efficiency | Higher fuel efficiency due to precise injection control | Good fuel efficiency but less optimized than ME |

| Emissions | Lower NOx and SOx emissions, compliant with IMO Tier III | Higher emissions, typically meets IMO Tier II |

| Maintenance | Requires specialized electronic expertise | More straightforward mechanical maintenance |

| Control System | Electronic control unit with real-time monitoring | Traditional mechanical governors |

| Startup | Smoother, automated startup | Manual startup procedures |

| Cost | Higher initial investment, lower operating cost | Lower upfront cost, potentially higher fuel costs |

| Reliability | High reliability with electronic backup systems | Proven mechanical reliability over decades |

Introduction to Marine Diesel Engines

Marine diesel engines are essential propulsion systems in the shipping industry, with Main Engine (ME) and Marine Control (MC) engines representing two key types. ME engines are directly connected to the ship's propeller, offering high efficiency and reliable power for large vessels, while MC engines provide auxiliary power and control functions essential for vessel operations. Understanding the differences in design, function, and application helps optimize vessel performance and fuel efficiency.

Overview of MC and ME Engine Technologies

ME engines, typically two-stroke and electronically controlled, optimize fuel injection and combustion for higher efficiency and lower emissions in large marine vessels. MC engines, commonly four-stroke and mechanically controlled, emphasize durability and ease of maintenance, widely used in medium-speed marine applications. Understanding the technological differences in your engine choice impacts fuel consumption, operational efficiency, and environmental compliance.

Key Design Differences: ME vs MC Engines

ME engines feature a slow-speed two-stroke design optimized for direct drive applications in large marine vessels, emphasizing fuel efficiency and durability. MC engines are medium-speed four-stroke engines designed for flexibility across marine and stationary power plants, offering balanced performance and easier maintenance. Key design differences include combustion cycles, speed ranges, and shaft configurations tailored to their specific operational roles.

Fuel Injection Systems: Electronic vs Mechanical

ME engines utilize advanced electronic fuel injection systems that optimize fuel delivery with precision sensors and computer controls, enhancing efficiency and emissions performance. MC engines rely on mechanical fuel injection mechanisms driven by camshafts, offering robustness but less adaptability to changing engine conditions. Your choice between these systems affects fuel economy, maintenance complexity, and emission standards compliance.

Performance and Efficiency Comparison

ME engines, or medium-speed diesel engines, deliver higher thermal efficiency and better fuel economy compared to MC engines, which are low-speed two-stroke engines primarily used for large marine propulsion. ME engines typically achieve specific fuel consumption around 160-170 g/kWh, while MC engines range between 175-185 g/kWh, highlighting ME's superior fuel efficiency. In terms of performance, ME engines offer faster response times and greater operational flexibility, whereas MC engines excel in durability and low-speed torque essential for large vessels.

Automation and Control Systems

The ME engine integrates advanced automation and control systems that optimize fuel efficiency and reduce emissions through real-time monitoring and adaptive adjustments. In contrast, the MC engine employs a more traditional mechanical control approach, relying on manual interventions and less sophisticated automation. Enhanced sensor networks and digitized control algorithms in ME engines significantly improve operational precision and maintenance scheduling compared to the conventional MC engine systems.

Maintenance Requirements and Reliability

ME engines generally have lower maintenance requirements due to their simpler design and direct fuel injection system, which enhances fuel efficiency and reduces wear. MC engines, with their more complex components and higher operating speeds, often demand more frequent inspections and part replacements to maintain optimal reliability. Choosing the right engine depends on your operational priorities, balancing maintenance workload against expected engine performance and longevity.

Environmental Impact and Emission Standards

ME engines, primarily two-stroke, are known for higher fuel efficiency and lower CO2 emissions compared to MC engines, which are four-stroke and often used for auxiliary purposes. ME engines meet stringent IMO Tier III emission standards by integrating advanced exhaust gas cleaning systems, significantly reducing NOx and SOx emissions. Your choice between ME and MC engines influences your vessel's environmental footprint and compliance with global emission regulations.

Operational Flexibility and Crew Training

ME engines offer greater operational flexibility by enabling independent control of each engine, allowing for optimized performance and fuel efficiency in varying conditions. Crew training for ME engines requires specialized knowledge of electronic control systems and automation, which can initially increase complexity but enhances overall operational precision. MC engines, while simpler in design and operation, demand more manual intervention and longer training periods focused on mechanical systems and manual control skills.

Future Trends in Marine Propulsion: ME and MC Engines

Future trends in marine propulsion emphasize the shift towards ME (Marine Engine) and MC (Marine Combustion) engines incorporating advanced fuel efficiency and reduced emissions technologies. ME engines leverage electronic control systems for precise fuel injection, enabling compatibility with alternative fuels such as LNG and methanol, supporting IMO 2030 and 2050 emission targets. MC engines focus on optimizing combustion processes and integrating hybrid solutions, promoting sustainability and compliance with evolving environmental regulations in the maritime industry.

ME engine vs MC engine Infographic

libmatt.com

libmatt.com