LNG carriers transport liquefied natural gas at extremely low temperatures around -162degC, requiring specialized insulated tanks to maintain this cryogenic state. LPG carriers ship liquefied petroleum gases like propane and butane under moderate pressure or refrigerated conditions, with different tank designs suited to their higher boiling points and storage requirements.

Table of Comparison

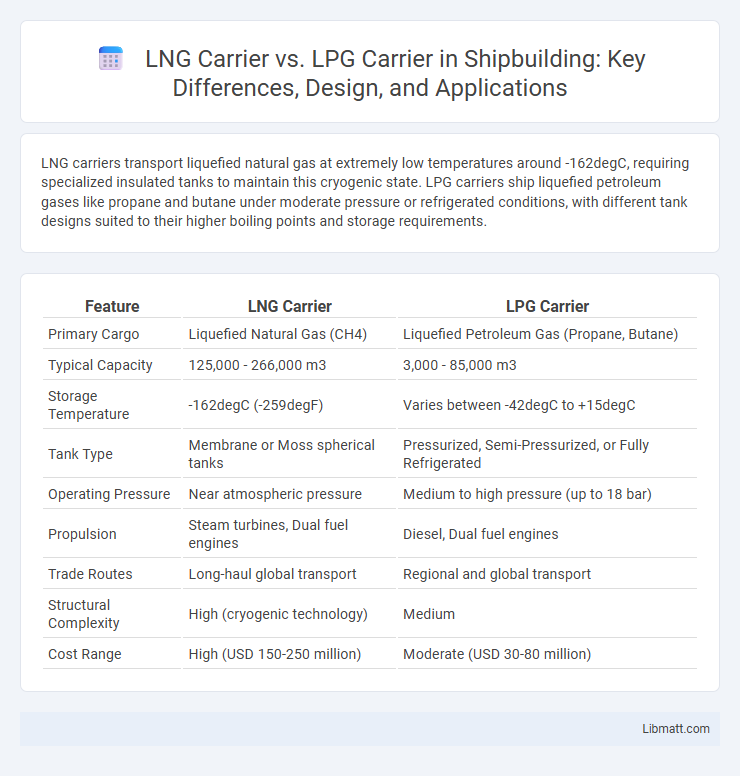

| Feature | LNG Carrier | LPG Carrier |

|---|---|---|

| Primary Cargo | Liquefied Natural Gas (CH4) | Liquefied Petroleum Gas (Propane, Butane) |

| Typical Capacity | 125,000 - 266,000 m3 | 3,000 - 85,000 m3 |

| Storage Temperature | -162degC (-259degF) | Varies between -42degC to +15degC |

| Tank Type | Membrane or Moss spherical tanks | Pressurized, Semi-Pressurized, or Fully Refrigerated |

| Operating Pressure | Near atmospheric pressure | Medium to high pressure (up to 18 bar) |

| Propulsion | Steam turbines, Dual fuel engines | Diesel, Dual fuel engines |

| Trade Routes | Long-haul global transport | Regional and global transport |

| Structural Complexity | High (cryogenic technology) | Medium |

| Cost Range | High (USD 150-250 million) | Moderate (USD 30-80 million) |

Introduction to LNG and LPG Carriers

LNG carriers transport liquefied natural gas at extremely low temperatures around -162degC, ensuring the gas remains in liquid form for efficient, long-distance shipping. LPG carriers, designed for liquefied petroleum gases such as propane and butane, operate at moderate pressures and temperatures, optimizing cargo stability and safety. Understanding these specialized vessels helps you appreciate their distinct technologies tailored for different gas types and transportation requirements.

Key Differences Between LNG and LPG Carriers

LNG carriers transport liquefied natural gas at approximately -162degC, requiring insulated tanks to maintain cryogenic temperatures, while LPG carriers handle liquefied petroleum gases like propane and butane at higher temperatures and moderate pressures. LNG carriers use spherical or membrane tanks designed for extreme cold, whereas LPG carriers employ pressure vessels or semi-pressurized tanks to contain gases under pressure. The cargo handling systems and safety measures differ significantly due to the distinct physical properties and storage conditions of LNG and LPG.

Design and Construction Features

LNG carriers feature spherical or membrane-type insulated tanks designed to maintain liquefied natural gas at -162degC, ensuring minimal boil-off and structural integrity under extreme cryogenic conditions. LPG carriers use cylindrical or Type C pressure vessels that store liquefied petroleum gases under higher pressure but at relatively warmer temperatures, emphasizing pressure resistance and tank flexibility. Your choice depends on cargo type, as LNG vessels prioritize thermal insulation while LPG carriers focus on pressure containment and adaptability.

Cargo Containment Systems

LNG carriers utilize membrane or spherical Moss-type cargo containment systems designed to handle liquefied natural gas at extremely low temperatures around -162degC, ensuring minimal boil-off and maintaining cargo integrity. LPG carriers commonly employ independent Type C pressure vessels or integral tanks insulated to withstand higher cargo temperatures typically between -50degC and ambient, facilitating the safe transport of liquefied petroleum gases under pressure. The design variations in containment systems between LNG and LPG carriers reflect the distinct thermodynamic properties and safety requirements of their respective cargoes.

Propulsion and Fuel Systems

LNG carriers use dual-fuel diesel-electric propulsion systems optimized for the cryogenic nature of liquefied natural gas, often utilizing boil-off gas as a fuel source to improve energy efficiency. LPG carriers typically employ diesel engines powered by heavy fuel oil or boil-off LPG, with propulsion systems designed to handle the higher volatility of liquefied petroleum gases. Your choice between these vessels impacts fuel consumption, emissions, and operational safety based on the specific fuel system configurations.

Loading and Unloading Procedures

LNG carriers utilize cryogenic temperatures around -162degC to load and unload liquefied natural gas via specialized insulated tanks and submerged pumps to maintain the gas in liquid form. LPG carriers operate with pressurized tanks, typically between 5 to 7 bar, enabling the loading and unloading of propane, butane, or their mixtures in liquid state at ambient or slightly refrigerated temperatures. Both types of carriers employ vapor recovery systems to capture boil-off gas, which is crucial for maintaining cargo integrity and minimizing emissions during the transfer processes.

Safety Measures and Regulations

LNG carriers operate under stringent safety regulations governed by the International Maritime Organization (IMO) and feature double-hull designs, advanced gas detection systems, and cryogenic containment to handle liquefied natural gas at extremely low temperatures. LPG carriers must comply with the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), featuring robust pressure vessels and comprehensive leak detection systems to safely transport propane, butane, and other liquefied petroleum gases. Your understanding of these distinct safety measures ensures compliance and risk mitigation in the specialized environments of LNG and LPG maritime transport.

Global Trade Routes and Market Demand

LNG carriers primarily serve extensive global trade routes connecting major producers like Qatar, Australia, and the United States with high-demand markets in Asia and Europe, reflecting the growing need for clean energy. LPG carriers operate on more regionally focused routes, facilitating trade between Middle Eastern exporters and markets in Asia, Africa, and Latin America, driven by LPG's use in heating, cooking, and petrochemical industries. Market demand for LNG is rapidly expanding due to stricter environmental regulations and energy transition policies, whereas LPG demand remains steady, sustained by its versatility and accessibility in emerging economies.

Environmental Impact and Emissions

LNG carriers and LPG carriers differ significantly in their environmental impact and emissions profiles due to the distinct properties of the gases they transport. LNG carriers typically emit lower levels of greenhouse gases and pollutants because liquefied natural gas has a higher energy density and burns cleaner compared to liquefied petroleum gas. Your choice between these vessels can influence operational sustainability, with LNG carriers generally offering a cleaner alternative aligned with stricter environmental regulations.

Future Trends in LNG and LPG Shipping

Future trends in LNG and LPG shipping highlight increasing demand for advanced, eco-friendly vessels equipped with improved fuel efficiency and reduced emissions technologies. LNG carriers are evolving with larger capacities and dual-fuel engines, while LPG carriers focus on greater versatility to transport diverse liquefied gases safely. Your shipping strategy should consider investments in these innovative technologies to meet stringent environmental regulations and capitalize on growing global energy markets.

LNG carrier vs LPG carrier Infographic

libmatt.com

libmatt.com