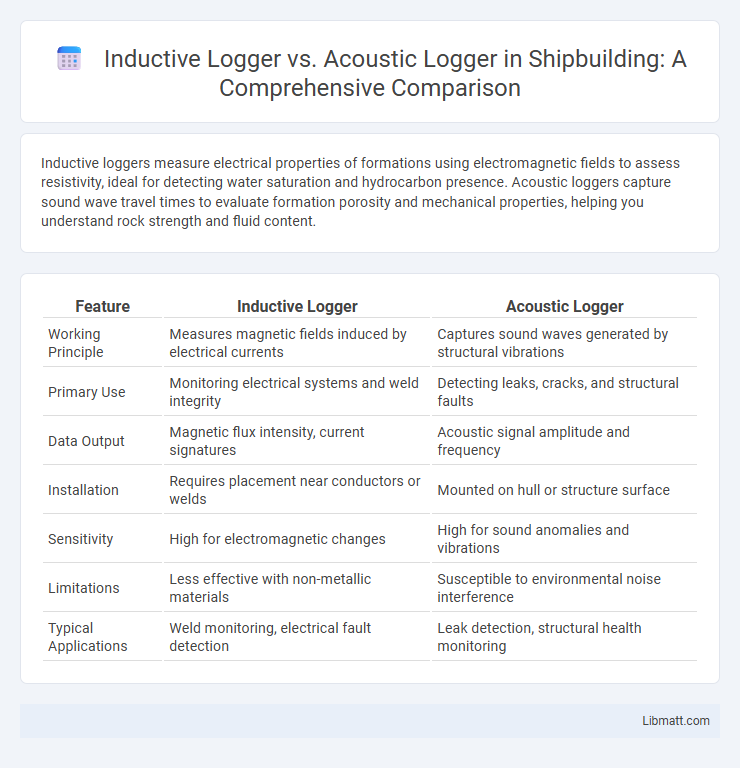

Inductive loggers measure electrical properties of formations using electromagnetic fields to assess resistivity, ideal for detecting water saturation and hydrocarbon presence. Acoustic loggers capture sound wave travel times to evaluate formation porosity and mechanical properties, helping you understand rock strength and fluid content.

Table of Comparison

| Feature | Inductive Logger | Acoustic Logger |

|---|---|---|

| Working Principle | Measures magnetic fields induced by electrical currents | Captures sound waves generated by structural vibrations |

| Primary Use | Monitoring electrical systems and weld integrity | Detecting leaks, cracks, and structural faults |

| Data Output | Magnetic flux intensity, current signatures | Acoustic signal amplitude and frequency |

| Installation | Requires placement near conductors or welds | Mounted on hull or structure surface |

| Sensitivity | High for electromagnetic changes | High for sound anomalies and vibrations |

| Limitations | Less effective with non-metallic materials | Susceptible to environmental noise interference |

| Typical Applications | Weld monitoring, electrical fault detection | Leak detection, structural health monitoring |

Introduction to Inductive and Acoustic Loggers

Inductive loggers utilize electromagnetic coupling to transmit and receive data through well casing, enabling precise measurement of downhole parameters such as temperature, pressure, and flow rate without direct electrical contact. Acoustic loggers operate by emitting sound waves into the wellbore and analyzing the reflected signals to assess formation properties, detect casing integrity, and evaluate fluid movement. Both technologies offer vital insights for reservoir characterization and production optimization, with inductive loggers excelling in electrically isolated environments while acoustic loggers provide high-resolution imaging of subsurface conditions.

How Inductive Loggers Work

Inductive loggers operate by emitting electromagnetic signals that induce currents in nearby metal pipes, allowing for precise measurement of pipe depth and location without direct contact. These devices are widely used in the oil and gas industry to trace casing and tubing accurately during well logging. Your ability to monitor subsurface structures improves significantly with inductive loggers due to their efficient and non-invasive detection method.

How Acoustic Loggers Operate

Acoustic loggers operate by emitting sound waves into geological formations and measuring the reflected acoustic signals to determine formation properties such as porosity and fluid content. These sensors detect variations in acoustic velocity and attenuation, which help identify lithology changes and fluid saturation levels. The high-resolution data from acoustic logging enhances reservoir characterization and formation evaluation effectiveness.

Key Differences Between Inductive and Acoustic Loggers

Inductive loggers use electromagnetic fields to transmit data through well casing, enabling real-time downhole communication without physical connections, while acoustic loggers rely on sound waves to send signals, often making them useful in environments where electromagnetic interference is high. You should consider that inductive loggers typically offer faster data transmission rates and higher reliability in deep wells, whereas acoustic loggers are more suited for fluid level measurements and dynamic flow monitoring. The key differences lie in their signal transmission methods, data speed, environmental adaptability, and application focus within well logging operations.

Data Accuracy: Inductive vs. Acoustic Loggers

Inductive loggers provide high data accuracy by directly measuring electromagnetic fields generated by well casings, resulting in precise depth and casing integrity readings. Acoustic loggers rely on sound wave travel times and reflections, which may be affected by formation heterogeneity and fluid properties, leading to potential variations in measurement accuracy. For applications requiring detailed casing inspection or depth correlation, inductive loggers typically deliver more consistently reliable data than acoustic loggers.

Installation and Maintenance Requirements

Inductive loggers require non-intrusive installation by coupling externally to pipeline structures, minimizing the need for direct fluid contact and reducing maintenance complexity. Acoustic loggers, however, often necessitate internal placement within the pipeline, leading to more invasive installation and higher maintenance frequencies due to exposure to corrosive fluids and sediment buildup. Maintenance for inductive loggers is typically less demanding, focused on external hardware checks, while acoustic loggers require regular calibration and cleaning to ensure signal accuracy.

Application Fields for Each Logger Type

Inductive loggers are extensively used in electromagnetic surveying, well logging for resistivity measurement, and corrosion monitoring in oil and gas wells, while acoustic loggers excel in applications requiring sound wave analysis such as formation evaluation, gas detection, and fracture identification in geological formations. Inductive loggers provide crucial data for identifying subsurface lithology and fluid content by measuring electrical properties, whereas acoustic loggers offer precise insights into rock mechanical properties and porosity through sonic and ultrasonic wave propagation. Both technologies play pivotal roles in optimizing hydrocarbon extraction by supplying complementary subsurface information tailored to specific reservoir characteristics.

Cost Considerations and ROI Analysis

Inductive loggers typically involve lower initial costs but may require more frequent maintenance, impacting long-term expenses, while acoustic loggers, though costlier upfront, often provide higher accuracy and durability, leading to potentially greater ROI in complex reservoir evaluations. The selection depends on project scale and data precision needs, as acoustic loggers offer enhanced signal quality that can reduce interpretation errors and operational risks, optimizing economic returns. Evaluating the total cost of ownership alongside production forecasting helps determine the most cost-effective logging technology for specific well conditions.

Advantages and Limitations of Inductive Loggers

Inductive loggers offer advantages such as faster data acquisition and less susceptibility to signal degradation in harsh downhole environments compared to acoustic loggers. They provide accurate measurement of formation resistivity, which is crucial for identifying hydrocarbon zones, but their performance can be limited by factors like borehole fluid conductivity and complex formation geometries. Your choice depends on specific well conditions and logging objectives, as inductive loggers are less effective in highly conductive muds or thin-bed formations.

Choosing the Right Logger for Your Project

Selecting the right logger for your project depends on factors like depth, environment, and data precision requirements. Inductive loggers excel in electrically conductive formations by providing accurate resistivity measurements, while acoustic loggers are ideal for evaluating formation porosity and mechanical properties through sound velocity analysis. Your choice should prioritize the specific geological conditions and data types critical to your analysis for optimal results.

Inductive logger vs acoustic logger Infographic

libmatt.com

libmatt.com