Plate girders offer strong shear resistance and are easily fabricated for variable spans, making them ideal for bridges with heavy loads, while box girders provide superior torsional stiffness and aerodynamic stability, especially beneficial for curved or long-span bridges. Choosing between them depends on Your project's specific structural requirements and environmental conditions.

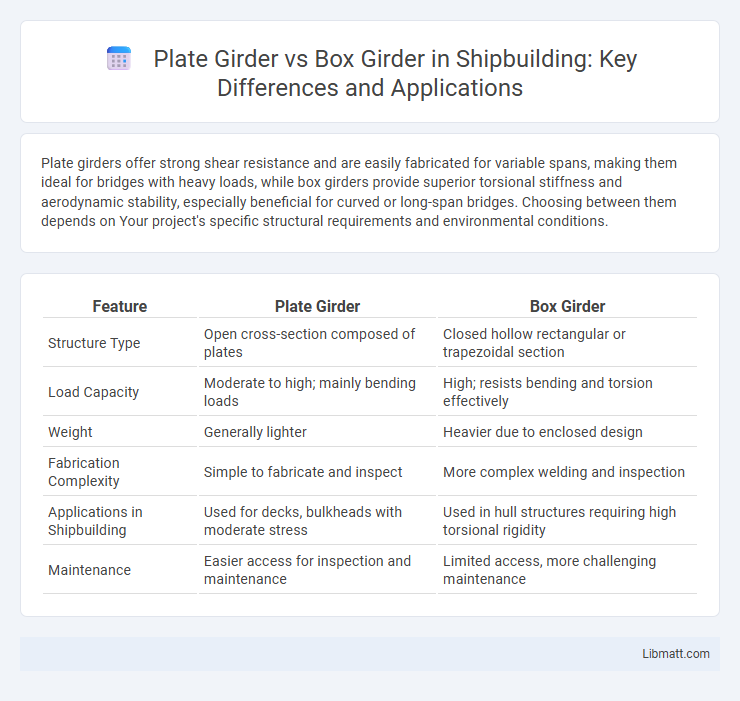

Table of Comparison

| Feature | Plate Girder | Box Girder |

|---|---|---|

| Structure Type | Open cross-section composed of plates | Closed hollow rectangular or trapezoidal section |

| Load Capacity | Moderate to high; mainly bending loads | High; resists bending and torsion effectively |

| Weight | Generally lighter | Heavier due to enclosed design |

| Fabrication Complexity | Simple to fabricate and inspect | More complex welding and inspection |

| Applications in Shipbuilding | Used for decks, bulkheads with moderate stress | Used in hull structures requiring high torsional rigidity |

| Maintenance | Easier access for inspection and maintenance | Limited access, more challenging maintenance |

Introduction to Plate Girders and Box Girders

Plate girders consist of steel plates welded or bolted together to form a deep beam, commonly used in bridges and building frameworks due to their high strength-to-weight ratio. Box girders feature a hollow, box-shaped cross-section providing excellent torsional rigidity, making them ideal for curved bridges and structures subjected to twisting forces. Your choice between plate girder and box girder depends on load requirements, structural form, and environmental conditions.

Structural Design Overview

Plate girders consist of a vertical web plate with horizontal flange plates welded or bolted to the top and bottom, providing high bending resistance primarily in one direction. Box girders feature a closed hollow rectangular or trapezoidal cross-section formed by welding or riveting four plates, offering superior torsional stiffness and resistance to torsional loads. Structural design considerations for plate girders prioritize flexural strength and shear capacity, while box girders are optimized for combined bending and torsion, making them suitable for curved or heavily loaded bridge spans.

Materials Used in Plate and Box Girders

Plate girders primarily use steel plates welded or riveted together to form an I-shaped cross-section, optimizing strength and weight for bridges and buildings. Box girders consist of steel or concrete panels forming a hollow box shape, offering superior torsional resistance and load distribution. Understanding the differences in material composition can help you select the appropriate girder type for structural efficiency and project requirements.

Load-Carrying Capacity Comparison

Plate girders and box girders differ significantly in load-carrying capacity due to their structural configurations; plate girders consist of flat steel plates welded to form an I-shaped cross-section, providing high bending resistance ideal for moderate to heavy loads. Box girders feature a closed cell rectangular or trapezoidal cross-section, offering superior torsional stiffness and enhanced load distribution, making them suitable for bridges and structures with complex loading conditions. Your choice of girder should consider the specific load requirements and span length, as box girders generally outperform plate girders in handling torsional and dynamic loads.

Construction Techniques and Challenges

Plate girders require fabrication by welding or bolting steel plates to form an I-shaped cross-section, which allows flexibility in size and strength but demands precise quality control and skilled labor to avoid defects. Box girders, typically constructed from steel or prestressed concrete, involve more complex assembly with closed-cell sections offering superior torsional rigidity but pose challenges in transportation and site assembly due to their bulk and intricacy. Both types necessitate careful consideration of load requirements and installation conditions to optimize structural performance and construction efficiency.

Applications in Bridge Engineering

Plate girders are commonly used in medium to long-span bridges due to their high strength-to-weight ratio and ease of fabrication, making them ideal for railway and highway bridges. Box girders offer superior torsional rigidity, which is essential for curved and complex bridge designs, often employed in modern cable-stayed and segmental bridges. Your choice depends on span length, load requirements, and geometric complexity to ensure optimal structural performance.

Advantages of Plate Girders

Plate girders offer superior strength-to-weight ratios compared to box girders, making them ideal for long-span bridges and heavy load applications. Their fabrication flexibility allows for easy customization in depth, flange, and web thickness to optimize material usage and structural performance. Plate girders also facilitate straightforward inspections and repairs due to their open-section design, enhancing maintenance efficiency over enclosed box girders.

Advantages of Box Girders

Box girders offer superior torsional rigidity and can efficiently resist large bending moments, making them ideal for curved and long-span bridges. Their closed-cell structure enhances stability and reduces susceptibility to buckling compared to plate girders. The aerodynamic shape of box girders also minimizes wind-induced vibrations, improving overall structural performance.

Cost and Maintenance Considerations

Plate girders generally offer lower initial costs due to simpler fabrication and material efficiency, making them cost-effective for moderate spans and varying load conditions. Box girders, while often more expensive upfront because of complex construction and higher material use, provide enhanced durability and resistance to torsional stresses, resulting in reduced long-term maintenance expenses. Maintenance of plate girders typically involves regular inspections for corrosion and fatigue cracks, whereas box girders require less frequent, but more specialized, upkeep to address potential internal access challenges.

Choosing Between Plate Girder and Box Girder

Choosing between plate girder and box girder depends on load capacity, span length, and structural efficiency. Plate girders offer simplicity and cost-effectiveness for moderate spans with concentrated loads, while box girders provide superior torsional resistance and stiffness ideal for curved or long-span bridges. Evaluating project-specific factors such as material availability, fabrication complexity, and maintenance requirements ensures optimal structural performance and durability.

Plate girder vs box girder Infographic

libmatt.com

libmatt.com