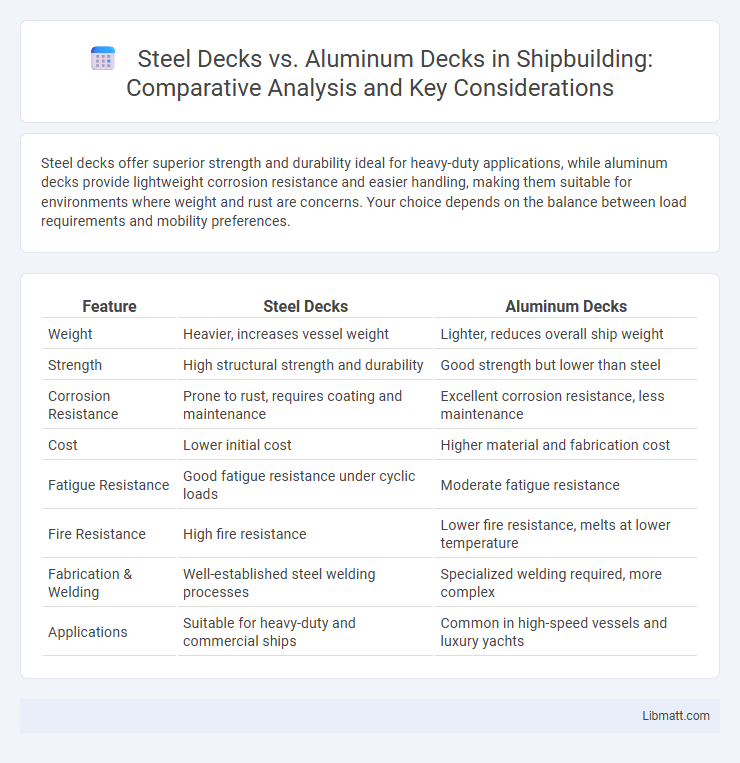

Steel decks offer superior strength and durability ideal for heavy-duty applications, while aluminum decks provide lightweight corrosion resistance and easier handling, making them suitable for environments where weight and rust are concerns. Your choice depends on the balance between load requirements and mobility preferences.

Table of Comparison

| Feature | Steel Decks | Aluminum Decks |

|---|---|---|

| Weight | Heavier, increases vessel weight | Lighter, reduces overall ship weight |

| Strength | High structural strength and durability | Good strength but lower than steel |

| Corrosion Resistance | Prone to rust, requires coating and maintenance | Excellent corrosion resistance, less maintenance |

| Cost | Lower initial cost | Higher material and fabrication cost |

| Fatigue Resistance | Good fatigue resistance under cyclic loads | Moderate fatigue resistance |

| Fire Resistance | High fire resistance | Lower fire resistance, melts at lower temperature |

| Fabrication & Welding | Well-established steel welding processes | Specialized welding required, more complex |

| Applications | Suitable for heavy-duty and commercial ships | Common in high-speed vessels and luxury yachts |

Introduction to Steel and Aluminum Decks

Steel decks offer exceptional strength, durability, and resistance to heavy loads, making them ideal for industrial and commercial applications where structural integrity is paramount. Aluminum decks provide a lightweight alternative with superior corrosion resistance, making them suitable for marine, transportation, and outdoor environments requiring ease of handling and long-term maintenance. Both materials deliver distinct performance benefits, with steel favoring strength and aluminum optimizing portability and resistance to environmental degradation.

Material Composition and Properties

Steel decks are composed primarily of carbon steel known for high tensile strength, durability, and resistance to deformation, making them ideal for heavy-duty construction applications. Aluminum decks consist of a lightweight alloy with excellent corrosion resistance and a higher strength-to-weight ratio, enhancing portability and reducing structural load. Both materials offer distinct mechanical properties, with steel providing superior load-bearing capacity while aluminum excels in environments prone to moisture and corrosion.

Strength and Durability Comparison

Steel decks exhibit superior strength and durability compared to aluminum decks, making them ideal for heavy-duty applications and high-load environments. Steel's higher tensile strength enables it to withstand significant impact and stress without deformation, while its corrosion resistance can be enhanced through galvanization or coatings. Aluminum decks offer lighter weight and natural corrosion resistance but generally lack steel's capacity to endure sustained heavy loads and abrasive conditions.

Weight and Structural Load Considerations

Steel decks offer superior strength and load-bearing capacity, making them ideal for heavy structural loads but they are significantly heavier, increasing the overall weight of your construction. Aluminum decks are much lighter, reducing structural load requirements and easing transportation and installation, but they may require reinforcement in applications with high load demands. Choosing between steel and aluminum decks requires balancing weight considerations against the structural load capacity needed for your project.

Corrosion Resistance and Maintenance

Aluminum decks exhibit superior corrosion resistance compared to steel decks due to aluminum's natural oxide layer, reducing the need for frequent maintenance and protective coatings. Steel decks, while stronger, require regular treatments such as galvanization or painting to prevent rust and extend lifespan, increasing maintenance efforts. Choosing aluminum decks can significantly lower long-term upkeep costs in environments prone to moisture and salt exposure.

Cost Analysis: Installation and Long-Term Value

Steel decks generally offer a lower initial installation cost compared to aluminum decks due to the abundance and lower raw material price of steel. Over the long term, steel decking provides superior durability and strength, reducing maintenance costs and ensuring better value in heavy-use applications. Your choice between steel and aluminum decks should consider not only upfront expenses but also factors like corrosion resistance, weight, and lifecycle cost to maximize investment returns.

Environmental Impact and Sustainability

Steel decks offer high recyclability, with up to 90% of steel content being recovered and reused, significantly reducing landfill waste and conserving natural resources. Aluminum decks, while lighter and corrosion-resistant, require more energy-intensive extraction and processing, leading to a larger carbon footprint compared to steel. Choosing steel decks supports sustainability efforts through longer service life and more efficient recycling infrastructures in the metal industry.

Installation Procedures and Ease

Steel decks feature heavier materials that require specialized tools and skilled labor for secure installation, often increasing project timelines and costs. Aluminum decks, being lighter and easier to handle, allow for quicker assembly with standard tools, reducing labor effort and facilitating easier modifications during installation. Your choice of deck material directly influences the complexity and duration of the installation process, impacting overall efficiency and budget.

Aesthetic Options and Customization

Steel decks offer a wide range of finish options including powder coating and painting, allowing for robust color customization and enhanced durability. Aluminum decks feature a naturally sleek, modern appearance with options for anodizing and various patterns, providing lightweight yet stylish aesthetic choices. Your preference for either material will influence the design flexibility, with steel decks excelling in customizable coatings and aluminum decks showcasing clean, corrosion-resistant finishes.

Best Applications: Choosing the Right Deck for Your Project

Steel decks offer superior strength and durability, making them ideal for heavy-duty construction projects such as commercial buildings, bridges, and industrial platforms. Aluminum decks provide lightweight corrosion resistance, perfect for marine environments, outdoor installations, and applications requiring easy mobility. Your choice should depend on load-bearing needs, environmental exposure, and project-specific weight constraints.

Steel decks vs aluminum decks Infographic

libmatt.com

libmatt.com