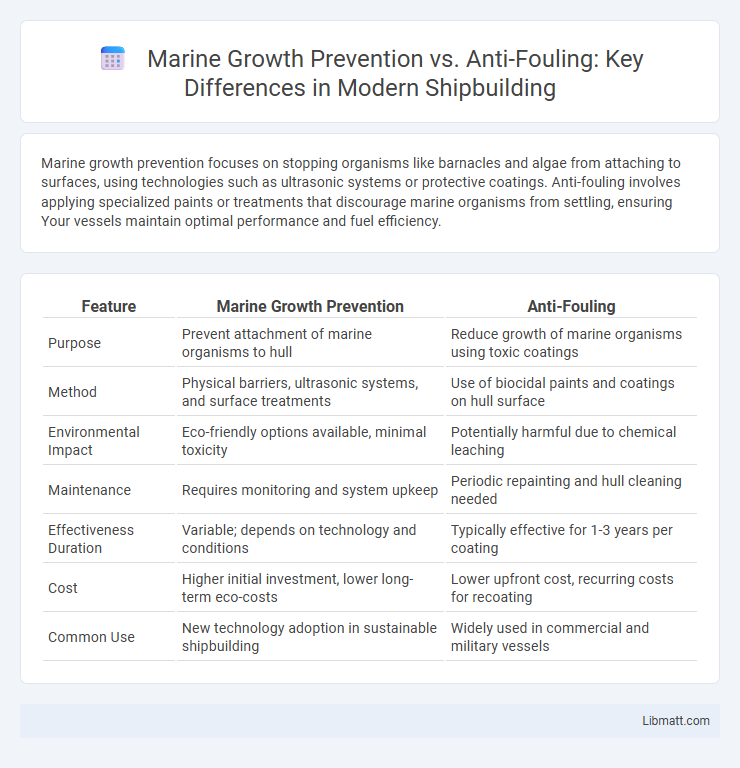

Marine growth prevention focuses on stopping organisms like barnacles and algae from attaching to surfaces, using technologies such as ultrasonic systems or protective coatings. Anti-fouling involves applying specialized paints or treatments that discourage marine organisms from settling, ensuring Your vessels maintain optimal performance and fuel efficiency.

Table of Comparison

| Feature | Marine Growth Prevention | Anti-Fouling |

|---|---|---|

| Purpose | Prevent attachment of marine organisms to hull | Reduce growth of marine organisms using toxic coatings |

| Method | Physical barriers, ultrasonic systems, and surface treatments | Use of biocidal paints and coatings on hull surface |

| Environmental Impact | Eco-friendly options available, minimal toxicity | Potentially harmful due to chemical leaching |

| Maintenance | Requires monitoring and system upkeep | Periodic repainting and hull cleaning needed |

| Effectiveness Duration | Variable; depends on technology and conditions | Typically effective for 1-3 years per coating |

| Cost | Higher initial investment, lower long-term eco-costs | Lower upfront cost, recurring costs for recoating |

| Common Use | New technology adoption in sustainable shipbuilding | Widely used in commercial and military vessels |

Introduction to Marine Growth and Fouling

Marine growth, including algae, barnacles, and mussels, adheres to submerged surfaces, causing biofouling that reduces vessel efficiency and accelerates corrosion. Marine growth prevention strategies aim to inhibit the initial settlement of organisms through physical or chemical means, while anti-fouling techniques employ specialized coatings that release biocides or create non-stick surfaces to deter fouling over time. Understanding the distinction between prevention and anti-fouling is crucial for maintaining hull integrity, optimizing fuel consumption, and extending the lifespan of marine structures.

Understanding Marine Growth Prevention

Marine growth prevention involves proactive measures to inhibit the attachment and proliferation of organisms like barnacles and algae on submerged surfaces, enhancing vessel efficiency and longevity. Unlike traditional anti-fouling coatings that primarily act as barriers, marine growth prevention focuses on advanced technologies such as ultrasonic systems and environmentally friendly coatings to reduce biofouling without harmful chemicals. Your choice in marine growth prevention techniques can significantly impact maintenance costs, fuel consumption, and environmental compliance in maritime operations.

Overview of Anti-Fouling Techniques

Anti-fouling techniques encompass various methods to prevent marine organisms from attaching to submerged surfaces, enhancing vessel performance and durability. Common approaches include biocidal coatings that release toxins to deter fouling, non-toxic foul-release coatings that create a slick surface preventing adhesion, and physical cleaning systems such as hull scrapers or ultrasonic devices. Your choice of anti-fouling solution depends on factors like vessel type, operating environment, and environmental regulations targeting marine growth prevention.

Key Differences Between Prevention and Anti-Fouling

Marine growth prevention involves proactive measures to hinder the attachment of organisms like algae and barnacles on submerged surfaces, using technologies such as ultrasonic systems or smooth coatings. Anti-fouling focuses on applying special paints or coatings embedded with biocides that actively kill or repel marine organisms to combat existing fouling. Understanding these key differences helps you select the most effective strategy for protecting vessels and underwater structures from biofouling-related damage.

Types of Marine Growth Prevention Methods

Marine growth prevention methods include physical, chemical, and biological approaches, such as ultrasonic antifouling systems, electrochlorination, and the application of non-toxic coatings. Anti-fouling techniques primarily rely on biocidal paints containing copper or organic boosters to inhibit organism attachment on ship hulls and submerged structures. Advanced solutions integrate sensors and real-time monitoring to optimize maintenance schedules and minimize environmental impact.

Popular Anti-Fouling Coatings and Technologies

Popular anti-fouling coatings include copper-based paints, foul-release coatings, and biocide-free silicone coatings designed to prevent organism adhesion on submerged surfaces. Marine growth prevention technologies focus on physical methods such as ultrasonic systems and electrochlorination, which inhibit biofilm formation without toxic chemicals. Innovations in anti-fouling continue to balance environmental safety with effectiveness in protecting ship hulls and marine infrastructure from barnacles, algae, and other biofouling organisms.

Environmental Impact: Prevention vs Anti-Fouling

Marine growth prevention methods, such as physical cleaning and ultrasonic treatments, minimize environmental impact by avoiding toxic substances in the water. Anti-fouling coatings often contain biocides like copper or other heavy metals, which can accumulate in marine ecosystems and harm aquatic life. Choosing prevention techniques reduces pollution risks and supports sustainable marine biodiversity management.

Cost Analysis: Marine Growth Prevention vs Anti-Fouling

Marine growth prevention methods generally require a higher initial investment compared to traditional anti-fouling coatings, but they offer long-term savings by reducing maintenance frequency and improving fuel efficiency. Anti-fouling paints incur lower upfront costs but demand regular reapplication, leading to cumulative expenses over time. Your choice should weigh these cost factors against operational needs to achieve optimal budget efficiency.

Maintenance Requirements and Longevity

Marine growth prevention systems typically require less frequent maintenance compared to traditional anti-fouling coatings, as they use physical or electrochemical methods to inhibit organism attachment. Anti-fouling paints demand regular reapplication every 1 to 3 years to maintain effectiveness against barnacles, algae, and other biofouling. In terms of longevity, marine growth prevention technologies often provide extended operational periods without intervention, improving vessel efficiency and reducing downtime.

Choosing the Best Solution for Your Vessel

Choosing the best solution for your vessel involves understanding the differences between marine growth prevention and anti-fouling methods. Marine growth prevention systems actively deter biofouling using technologies like ultrasonic waves or copper ionization, offering long-term protection without harmful chemicals, whereas anti-fouling paints create a toxic barrier that prevents organism attachment but require regular reapplication. Your vessel's operational profile, environmental regulations, and maintenance capabilities are key factors in selecting the most effective and sustainable approach.

Marine growth prevention vs anti-fouling Infographic

libmatt.com

libmatt.com