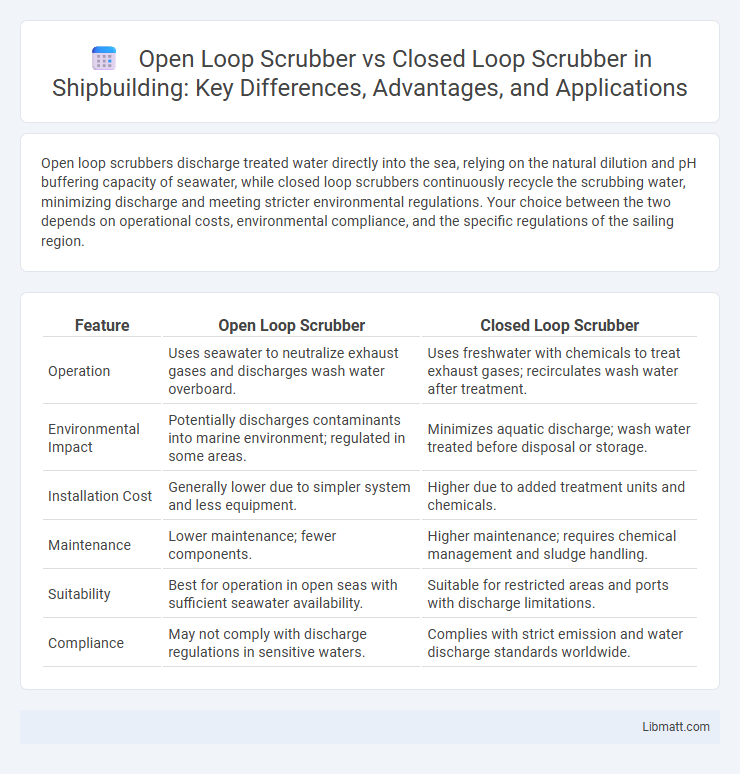

Open loop scrubbers discharge treated water directly into the sea, relying on the natural dilution and pH buffering capacity of seawater, while closed loop scrubbers continuously recycle the scrubbing water, minimizing discharge and meeting stricter environmental regulations. Your choice between the two depends on operational costs, environmental compliance, and the specific regulations of the sailing region.

Table of Comparison

| Feature | Open Loop Scrubber | Closed Loop Scrubber |

|---|---|---|

| Operation | Uses seawater to neutralize exhaust gases and discharges wash water overboard. | Uses freshwater with chemicals to treat exhaust gases; recirculates wash water after treatment. |

| Environmental Impact | Potentially discharges contaminants into marine environment; regulated in some areas. | Minimizes aquatic discharge; wash water treated before disposal or storage. |

| Installation Cost | Generally lower due to simpler system and less equipment. | Higher due to added treatment units and chemicals. |

| Maintenance | Lower maintenance; fewer components. | Higher maintenance; requires chemical management and sludge handling. |

| Suitability | Best for operation in open seas with sufficient seawater availability. | Suitable for restricted areas and ports with discharge limitations. |

| Compliance | May not comply with discharge regulations in sensitive waters. | Complies with strict emission and water discharge standards worldwide. |

Introduction to Marine Scrubber Systems

Marine scrubber systems are essential for reducing sulfur oxide emissions from ship exhaust gases, meeting international environmental regulations. Open loop scrubbers use seawater to wash pollutants and discharge the water back into the ocean, making them suitable for vessels operating in open seas. Closed loop scrubbers recirculate cleaning water with chemical additives, minimizing discharge and allowing Your ship to comply with stricter environmental zones or ports with discharge restrictions.

What is an Open Loop Scrubber?

An Open Loop Scrubber is a maritime exhaust gas cleaning system that uses seawater to remove sulfur oxides (SOx) from ship emissions. It continuously discharges the wash water back into the ocean after neutralizing the pollutants, relying on the alkalinity of seawater for scrubbing. This system is often favored for its simpler design, lower initial cost, and suitability in areas with unrestricted water discharge regulations.

What is a Closed Loop Scrubber?

A closed loop scrubber is a marine exhaust gas cleaning system designed to remove sulfur oxides (SOx) from ship emissions by continuously recirculating and treating wash water within a sealed system. It uses freshwater mixed with an alkaline additive, such as sodium hydroxide, to neutralize acidic gases, ensuring minimal discharge of pollutants into the environment. This system is especially advantageous in environmentally sensitive areas due to its reduced water discharge and compliance with stringent emission regulations.

Key Differences Between Open Loop and Closed Loop Scrubbers

Open loop scrubbers discharge treated seawater directly back into the ocean, utilizing natural seawater to neutralize emissions, while closed loop scrubbers recycle wash water in a contained system, minimizing environmental discharge. Key differences include their operational environments, with open loop systems being more suited to ships operating in open seas, and closed loop scrubbers ideal for restricted or sensitive waters where discharge must be controlled. Your choice depends on regulatory requirements, environmental impact considerations, and vessel operational areas.

Environmental Impact: Open Loop vs Closed Loop

Open loop scrubbers discharge wash water directly into the sea, which can contain pollutants and affect marine ecosystems, though they use seawater and have lower freshwater consumption. Closed loop scrubbers recycle wash water through a treatment system to remove contaminants before discharge, significantly reducing environmental harm and minimizing chemical use. Your choice between open loop and closed loop scrubbers directly influences the level of marine pollution and compliance with environmental regulations.

Compliance with IMO 2020 Regulations

Open loop scrubbers use seawater to remove sulfur oxides from exhaust gases, but their discharge restrictions limit their use in certain Emission Control Areas (ECAs), impacting compliance with IMO 2020 regulations. Closed loop scrubbers utilize freshwater with chemical additives and recirculate the wash water, allowing consistent sulfur removal and easier adherence to IMO 2020 sulfur cap requirements worldwide. Your choice between these systems depends on operational routes and specific regulatory environments to ensure optimal compliance.

Installation and Operational Costs

Open loop scrubbers generally feature lower installation costs due to simpler system designs and fewer onboard components. Operational expenses for open loop systems can be reduced if seawater conditions are favorable, as they rely on natural seawater for scrubbing without the need for chemical additives. Closed loop scrubbers incur higher initial installation costs because of additional equipment such as neutralization tanks and dosing systems, but offer more consistent performance in varied water conditions, potentially stabilizing your operational budget over time.

Maintenance Requirements and Challenges

Open loop scrubbers generally require less frequent maintenance due to their simpler design and reliance on seawater for scrubbing, but they face challenges with fouling and scaling from untreated seawater intake. Closed loop scrubbers demand more intensive maintenance because of their complex systems, including chemical dosing and sludge handling, which can lead to higher operational costs and frequent component replacements. Both systems require regular cleaning of scrubber units and monitoring of corrosion, but closed loop systems often need more specialized expertise to manage their chemical treatment processes effectively.

Suitability for Different Vessel Types

Open loop scrubbers are well-suited for vessels frequently operating in open seas with abundant water exchange, such as bulk carriers and container ships, due to their reliance on seawater for scrubbing emissions. Closed loop scrubbers are ideal for vessels like cruise ships and ferries that operate in areas with strict discharge regulations or limited water exchange, as they recycle wash water and minimize environmental impact. Your choice depends on vessel type, operational area, and compliance with regional environmental regulations.

Future Trends in Scrubber Technology

Future trends in scrubber technology highlight advancements in both open loop and closed loop systems, emphasizing increased efficiency and environmental compliance. Open loop scrubbers are evolving with improved water treatment methods to minimize marine pollution, while closed loop scrubbers are adopting advanced filtration and chemical regeneration techniques to enhance sustainability. Your choice will benefit from ongoing innovations that reduce operational costs and meet stricter global emission regulations.

Open loop scrubber vs closed loop scrubber Infographic

libmatt.com

libmatt.com