A box-shaped hold offers uniform space ideal for stacking pallets securely, while a hopper hold features sloped sides to facilitate efficient unloading of bulk materials like grain or coal. Choosing between them depends on your cargo type and handling requirements to optimize storage and transport efficiency.

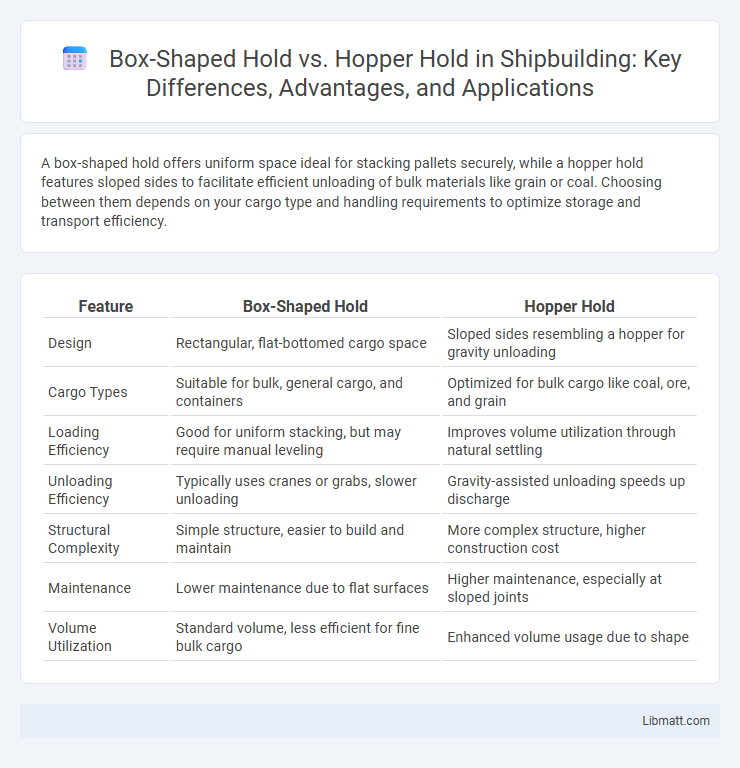

Table of Comparison

| Feature | Box-Shaped Hold | Hopper Hold |

|---|---|---|

| Design | Rectangular, flat-bottomed cargo space | Sloped sides resembling a hopper for gravity unloading |

| Cargo Types | Suitable for bulk, general cargo, and containers | Optimized for bulk cargo like coal, ore, and grain |

| Loading Efficiency | Good for uniform stacking, but may require manual leveling | Improves volume utilization through natural settling |

| Unloading Efficiency | Typically uses cranes or grabs, slower unloading | Gravity-assisted unloading speeds up discharge |

| Structural Complexity | Simple structure, easier to build and maintain | More complex structure, higher construction cost |

| Maintenance | Lower maintenance due to flat surfaces | Higher maintenance, especially at sloped joints |

| Volume Utilization | Standard volume, less efficient for fine bulk cargo | Enhanced volume usage due to shape |

Introduction to Box-Shaped Hold and Hopper Hold

Box-shaped holds are characterized by their rectangular or square cross-sections, providing uniform stability and maximizing cargo space utilization in vessels. Hopper holds feature tapered sides that funnel cargo downward, enhancing self-trimming and facilitating easier unloading of bulk materials like coal or grain. Both hold types are designed to optimize storage efficiency but differ significantly in structural shape and cargo handling capabilities.

Defining Box-Shaped Hold

A box-shaped hold refers to a cargo space design characterized by a rectangular, uniform shape with flat walls and a flat bottom, facilitating efficient stacking and maximizing usable volume. This design contrasts with hopper holds, which have sloped sides to aid in gravity discharge of bulk materials. Box-shaped holds are ideal for general cargo requiring stable stacking and easy access during loading and unloading processes.

Understanding Hopper Hold Design

Hopper hold design maximizes cargo efficiency by incorporating sloped walls that facilitate gravity-assisted unloading, reducing the need for manual labor and equipment. Unlike box-shaped holds with straight vertical walls, hopper holds enable faster discharge of bulk materials such as coal, grain, or ore through bottom hopper doors. This design optimization improves turnaround times in shipping operations and enhances overall cargo handling productivity.

Key Differences Between Box-Shaped and Hopper Holds

Box-shaped holds feature rectangular or square compartments providing uniform storage space ideal for stacking and organizing standardized cargo, while hopper holds have sloped sides that facilitate gravity-assisted unloading, enhancing efficiency for bulk materials like grains or coal. The structural design of box-shaped holds supports heavier loads and maximizes volume utilization, contrasting with hopper holds optimized for ease of discharge but limited in cargo variety. Maintenance and operational costs differ as box-shaped holds may require more manual handling, whereas hopper holds reduce labor through streamlined unloading mechanisms.

Structural Benefits of Box-Shaped Holds

Box-shaped holds offer superior structural integrity due to their reinforced square or rectangular design, which evenly distributes loads and minimizes stress points. This design enhances durability and reduces the risk of deformation under heavy cargo, ensuring secure storage for your goods. Their rigid construction commonly results in easier stacking and efficient space utilization compared to hopper holds.

Advantages of Hopper Holds

Hopper holds offer increased flexibility and efficiency in cargo handling due to their sloped walls that facilitate gravity-assisted unloading and reduce manual labor. These holds allow faster discharge rates, minimizing vessel turnaround time and operational costs. Their design accommodates bulk commodities such as grains, coal, and ores more effectively than box-shaped holds, improving overall cargo flow and storage capacity.

Cargo Compatibility: Box-Shaped vs Hopper Holds

Box-shaped holds offer versatile cargo compatibility, accommodating palletized goods, containers, and packaged products due to their uniform shape and flat surfaces. Hopper holds are specifically designed for bulk cargo such as coal, grain, or ores, featuring sloped walls that facilitate gravity-assisted unloading but limit the carriage of packaged or containerized items. The choice between box-shaped and hopper holds directly impacts cargo type flexibility and operational efficiency during loading and discharge processes.

Loading and Unloading Efficiency Comparison

Box-shaped holds provide higher loading and unloading efficiency due to their uniform, rectangular shape, enabling easier stacking and faster crane operation. Hopper holds have tapered sides which can complicate cargo flow, requiring additional handling to prevent material bridging and slower discharge rates. Your choice between these holds should consider the priority of speed and simplicity in cargo operations.

Maintenance and Operational Considerations

Box-shaped holds offer easier maintenance due to their straightforward, flat surfaces that facilitate quick cleaning and inspection, reducing downtime and operational costs. Hopper holds, with their angled walls designed for gravity-assisted unloading, require more frequent inspection to prevent material buildup and corrosion in corners. Your operational efficiency depends on selecting the hold type that aligns with your cargo handling and maintenance capabilities.

Choosing the Appropriate Hold Design for Vessels

Selecting the appropriate hold design for vessels depends primarily on cargo type and operational efficiency requirements. Box-shaped holds offer versatile, maximized cubic capacity suited for general and containerized cargo, facilitating easier loading and unloading with standard equipment. Hopper holds, designed with sloping sides, enhance bulk cargo discharge by promoting gravity flow, reducing residue, and minimizing cleaning time, ideal for mines, grains, and loose commodities.

Box-shaped hold vs hopper hold Infographic

libmatt.com

libmatt.com