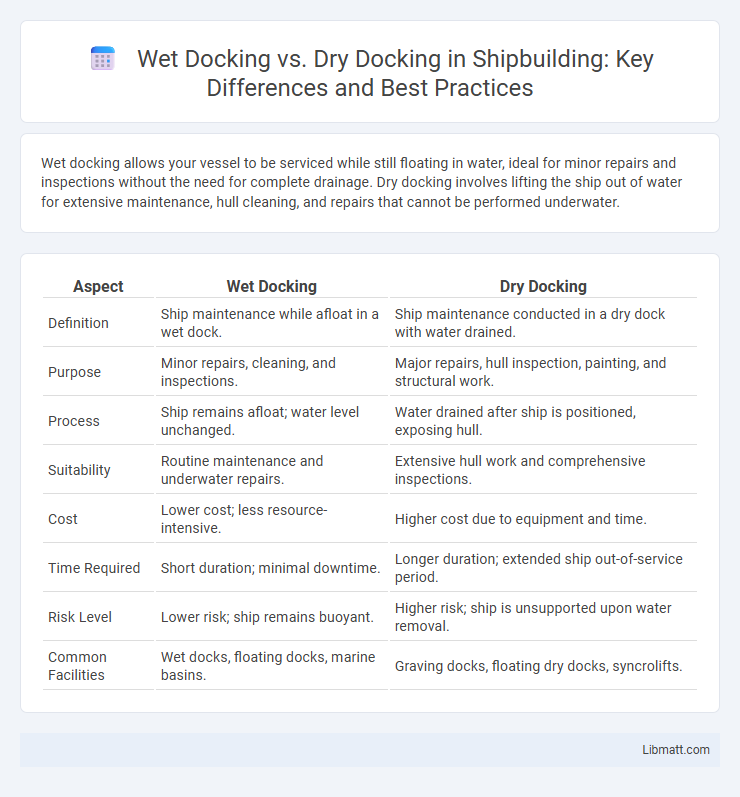

Wet docking allows your vessel to be serviced while still floating in water, ideal for minor repairs and inspections without the need for complete drainage. Dry docking involves lifting the ship out of water for extensive maintenance, hull cleaning, and repairs that cannot be performed underwater.

Table of Comparison

| Aspect | Wet Docking | Dry Docking |

|---|---|---|

| Definition | Ship maintenance while afloat in a wet dock. | Ship maintenance conducted in a dry dock with water drained. |

| Purpose | Minor repairs, cleaning, and inspections. | Major repairs, hull inspection, painting, and structural work. |

| Process | Ship remains afloat; water level unchanged. | Water drained after ship is positioned, exposing hull. |

| Suitability | Routine maintenance and underwater repairs. | Extensive hull work and comprehensive inspections. |

| Cost | Lower cost; less resource-intensive. | Higher cost due to equipment and time. |

| Time Required | Short duration; minimal downtime. | Longer duration; extended ship out-of-service period. |

| Risk Level | Lower risk; ship remains buoyant. | Higher risk; ship is unsupported upon water removal. |

| Common Facilities | Wet docks, floating docks, marine basins. | Graving docks, floating dry docks, syncrolifts. |

Introduction to Wet Docking and Dry Docking

Wet docking involves servicing a vessel while it remains afloat in a dock filled with water, allowing inspections and minor repairs without removing the ship from the water. Dry docking requires the vessel to be lifted out of the water onto a specialized platform, providing full access to the hull for extensive maintenance, painting, and structural repairs. Understanding the difference between wet docking and dry docking helps you determine the appropriate method for scheduled maintenance or emergency repairs based on your vessel's needs.

Key Differences Between Wet Docking and Dry Docking

Wet docking involves servicing a ship while it remains afloat in water, allowing for minor repairs and maintenance without removing the vessel from its natural environment. Dry docking requires the ship to be lifted out of water onto a dry platform, enabling extensive inspections, hull repairs, and propeller maintenance that cannot be performed underwater. Your choice depends on the scope and urgency of repairs, with dry docking offering more comprehensive access but requiring more time and resources.

Advantages of Wet Docking

Wet docking offers significant advantages such as reduced downtime and lower costs since the vessel remains afloat, eliminating the need for extensive preparation. Maintenance tasks like hull cleaning, propeller polishing, and minor repairs can be efficiently performed without removing the ship from the water. You benefit from faster turnaround times and minimized operational disruptions compared to dry docking procedures.

Advantages of Dry Docking

Dry docking offers superior inspection and maintenance capabilities by allowing full access to a vessel's hull, propellers, and underwater components, which remain submerged during wet docking. This method facilitates comprehensive repairs, cleaning, and coating applications essential for preventing corrosion and marine growth. Dry docking also ensures enhanced safety for workers and equipment, minimizing risks associated with underwater operations.

Limitations of Wet Docking

Wet docking presents limitations such as restricted access to the ship's hull below the waterline, making detailed inspections and repairs challenging. The continuous presence of water can complicate maintenance tasks like cleaning, painting, or structural repairs due to moisture and underwater pressure. Furthermore, wet docking is less suitable for vessels requiring extensive hull modifications or heavy repairs that demand a dry, stable environment.

Limitations of Dry Docking

Dry docking involves lifting a ship out of the water for inspection, maintenance, and repairs, but it has limitations such as high operational costs and time-consuming setup processes. Structural constraints of some vessels prevent dry docking due to their size or fragility, making wet docking a necessary alternative. Additionally, weather conditions and dock availability can cause delays, further limiting the efficiency of dry docking operations.

Cost Comparison: Wet Docking vs Dry Docking

Wet docking typically incurs lower costs than dry docking due to reduced labor and equipment expenses, as the vessel remains afloat during inspection and minor repairs. Dry docking, while more expensive, allows for comprehensive maintenance and hull repairs that cannot be performed underwater, justifying its higher price through extensive service capabilities. Your choice depends on the scope of work needed and budget constraints, balancing immediate costs against long-term vessel upkeep.

Safety Considerations in Both Docking Methods

Wet docking involves maintaining a vessel afloat in a controlled water environment, reducing structural stress but requiring strict monitoring of hull integrity to prevent water ingress. Dry docking offers direct access for thorough inspection and repair, enhancing safety through complete dewatering and stable support, but poses risks related to hull support placement and potential slips. Your choice between wet and dry docking should prioritize specific safety protocols relevant to the vessel's condition and maintenance needs.

Choosing the Right Docking Method for Your Vessel

Selecting the appropriate docking method for your vessel depends on its maintenance needs, size, and operational schedule. Wet docking allows routine inspections and minor repairs without removing the vessel from water, making it ideal for quick servicing and minimizing downtime. Dry docking, involving complete water removal to expose the hull, suits extensive repairs, painting, and structural assessments critical for long-term vessel performance and safety.

Future Trends in Docking Technology

Future trends in docking technology emphasize the integration of automated systems and smart sensors to enhance precision and safety in both wet docking and dry docking processes. Innovations such as robotic arms and AI-powered diagnostics enable real-time monitoring of hull conditions, reducing maintenance time and costs. Advances in environmentally friendly materials and energy-efficient docking systems aim to minimize ecological impact while improving operational efficiency in shipyards worldwide.

Wet docking vs dry docking Infographic

libmatt.com

libmatt.com