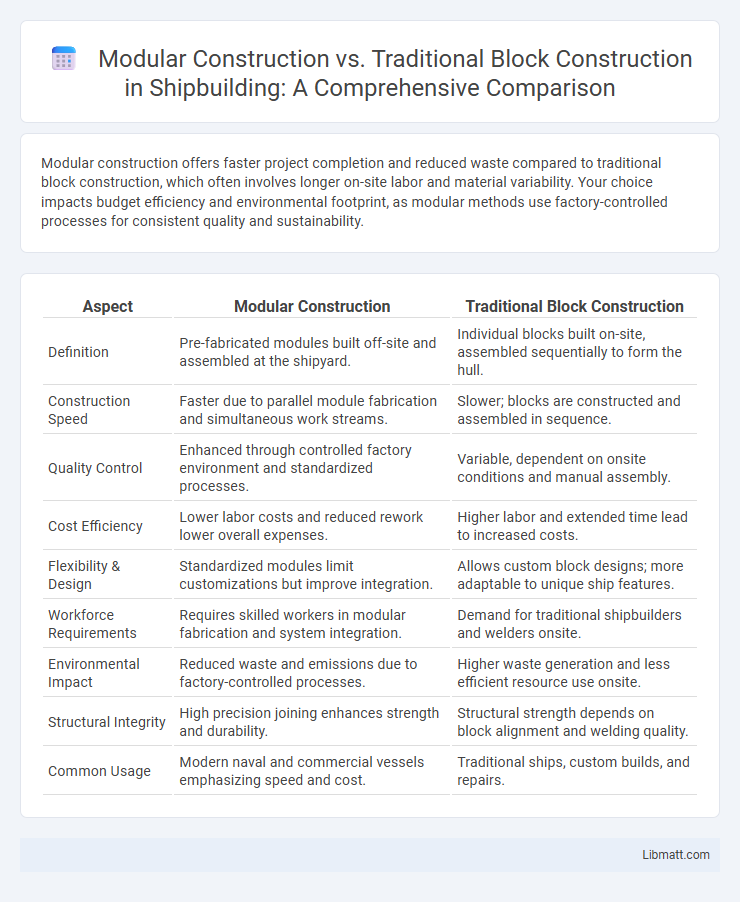

Modular construction offers faster project completion and reduced waste compared to traditional block construction, which often involves longer on-site labor and material variability. Your choice impacts budget efficiency and environmental footprint, as modular methods use factory-controlled processes for consistent quality and sustainability.

Table of Comparison

| Aspect | Modular Construction | Traditional Block Construction |

|---|---|---|

| Definition | Pre-fabricated modules built off-site and assembled at the shipyard. | Individual blocks built on-site, assembled sequentially to form the hull. |

| Construction Speed | Faster due to parallel module fabrication and simultaneous work streams. | Slower; blocks are constructed and assembled in sequence. |

| Quality Control | Enhanced through controlled factory environment and standardized processes. | Variable, dependent on onsite conditions and manual assembly. |

| Cost Efficiency | Lower labor costs and reduced rework lower overall expenses. | Higher labor and extended time lead to increased costs. |

| Flexibility & Design | Standardized modules limit customizations but improve integration. | Allows custom block designs; more adaptable to unique ship features. |

| Workforce Requirements | Requires skilled workers in modular fabrication and system integration. | Demand for traditional shipbuilders and welders onsite. |

| Environmental Impact | Reduced waste and emissions due to factory-controlled processes. | Higher waste generation and less efficient resource use onsite. |

| Structural Integrity | High precision joining enhances strength and durability. | Structural strength depends on block alignment and welding quality. |

| Common Usage | Modern naval and commercial vessels emphasizing speed and cost. | Traditional ships, custom builds, and repairs. |

Overview of Modular and Traditional Block Construction

Modular construction involves fabricating building sections in a factory setting before assembling them onsite, reducing construction time and waste significantly. Traditional block construction relies on the sequential laying of concrete or cement blocks onsite, allowing for customization but often extending project duration. Your choice depends on priorities like speed, cost-efficiency, and design flexibility.

Key Differences Between Modular and Block Construction

Modular construction involves prefabricating sections of a building in a controlled factory environment, ensuring faster assembly and reduced on-site labor compared to traditional block construction, which requires assembling individual blocks manually on-site. Modular units are engineered with precise specifications and integrated systems, resulting in consistent quality and less material waste, whereas block construction is more labor-intensive and susceptible to environmental conditions that can affect curing and structural integrity. Cost efficiency, construction speed, and sustainability are significant advantages of modular construction over traditional block construction methods.

Speed and Efficiency of Building Processes

Modular construction accelerates building processes by producing components in controlled factory environments, allowing simultaneous site preparation and module fabrication, which can reduce project timelines by up to 50% compared to traditional block construction. Traditional block construction relies heavily on sequential on-site work, often extending schedules due to weather delays and material curing times. The efficiency of modular construction minimizes labor costs and site disturbances, enabling faster occupancy and improved project predictability.

Cost Comparison: Modular vs. Block Construction

Modular construction offers significant cost savings compared to traditional block construction due to reduced labor expenses and shorter project timelines, often cutting overall costs by 20-30%. Prefabrication in controlled factory settings minimizes material waste and weather-related delays, further lowering expenses. Your project budget can benefit from these efficiencies, making modular construction a cost-effective alternative to conventional block building.

Material Quality and Sustainability

Modular construction utilizes factory-controlled processes to ensure consistent material quality, reducing waste and defects compared to traditional block construction, which often experiences variability due to on-site conditions. The use of prefabricated components allows modular methods to incorporate sustainable materials and energy-efficient designs more effectively, promoting eco-friendly building practices. Traditional block construction typically involves higher material waste and longer construction times, resulting in increased environmental impact and reduced sustainability.

Flexibility and Design Options

Modular construction offers enhanced flexibility and design options through prefabricated components that can be easily customized, reconfigured, or expanded, allowing for innovative architectural designs and faster project adjustments. Traditional block construction is often limited by on-site constraints and labor-intensive processes, resulting in less adaptability for complex or evolving design requirements. Modular methods support scalable and sustainable building solutions that accommodate diverse aesthetic and functional needs efficiently.

Site Preparation and Logistics

Modular construction significantly reduces site preparation time by assembling components off-site in controlled factory settings, minimizing on-site labor and disruptions. Traditional block construction requires extensive groundwork, including foundation setting and material staging, causing longer project timelines and more complex logistics. Efficient transportation and precise scheduling are critical in modular construction to ensure timely delivery and installation of prefabricated modules.

Structural Strength and Durability

Modular construction offers enhanced structural strength through factory-controlled precision and the use of high-quality materials, ensuring uniform durability and resistance to environmental stresses. Traditional block construction relies on site-built methods that may vary in quality and are more susceptible to weather and workmanship inconsistencies, potentially affecting long-term durability. Your choice between these methods impacts the overall resilience and lifespan of the building, with modular systems often providing superior strength and consistent performance.

Environmental Impact and Waste Reduction

Modular construction significantly reduces environmental impact by minimizing material waste through precise factory fabrication and optimized resource use, contrasting with traditional block construction which generates considerable onsite debris and excess materials. The controlled environment in modular manufacturing allows for efficient recycling and reuse of scraps that typically end up in landfills with conventional methods. Reduced transportation emissions also contribute to lower carbon footprints in modular builds, highlighting its sustainability advantage over traditional block construction.

Future Trends in Construction Methods

Modular construction is rapidly influencing the future of building methods by offering faster project completion, reduced waste, and enhanced sustainability compared to traditional block construction. Innovations in prefab technology and digital design integration are driving cost efficiency and customization, making modular systems a preferred choice in urban development and emergency housing. Your projects can benefit from these advancements through scalable solutions that adapt to evolving environmental regulations and labor market challenges.

Modular construction vs traditional block construction Infographic

libmatt.com

libmatt.com