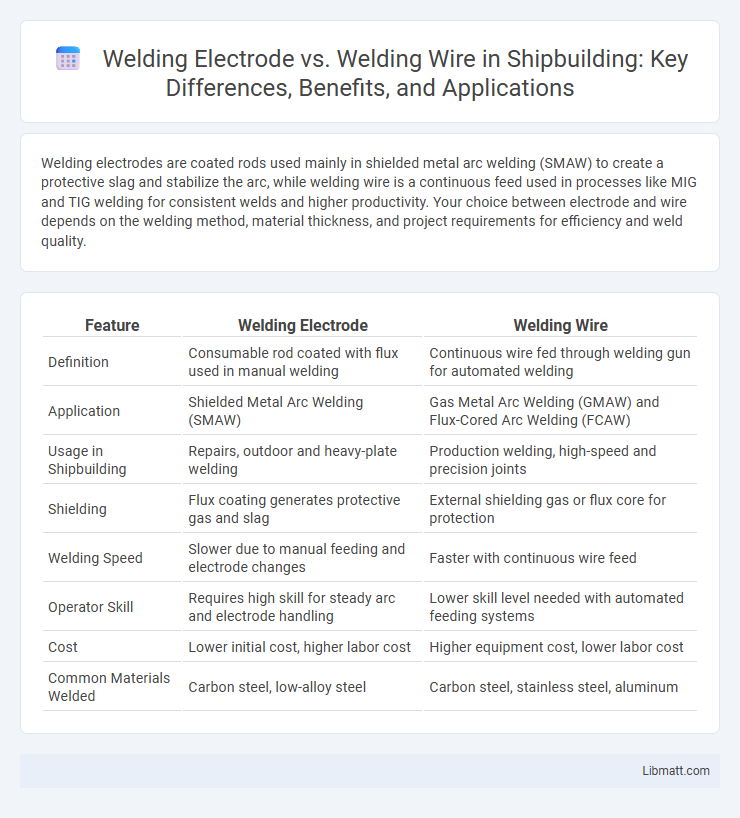

Welding electrodes are coated rods used mainly in shielded metal arc welding (SMAW) to create a protective slag and stabilize the arc, while welding wire is a continuous feed used in processes like MIG and TIG welding for consistent welds and higher productivity. Your choice between electrode and wire depends on the welding method, material thickness, and project requirements for efficiency and weld quality.

Table of Comparison

| Feature | Welding Electrode | Welding Wire |

|---|---|---|

| Definition | Consumable rod coated with flux used in manual welding | Continuous wire fed through welding gun for automated welding |

| Application | Shielded Metal Arc Welding (SMAW) | Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW) |

| Usage in Shipbuilding | Repairs, outdoor and heavy-plate welding | Production welding, high-speed and precision joints |

| Shielding | Flux coating generates protective gas and slag | External shielding gas or flux core for protection |

| Welding Speed | Slower due to manual feeding and electrode changes | Faster with continuous wire feed |

| Operator Skill | Requires high skill for steady arc and electrode handling | Lower skill level needed with automated feeding systems |

| Cost | Lower initial cost, higher labor cost | Higher equipment cost, lower labor cost |

| Common Materials Welded | Carbon steel, low-alloy steel | Carbon steel, stainless steel, aluminum |

Introduction to Welding Electrode and Welding Wire

Welding electrodes and welding wires serve distinct roles in the welding process, with electrodes commonly used in stick welding (SMAW) to conduct current and provide filler material, while welding wires are primarily utilized in MIG (GMAW) and TIG (GTAW) welding for continuous filler metal feed. Electrodes consist of a core wire coated with flux, which stabilizes the arc and protects the weld pool from oxidation and contamination. In contrast, welding wire is typically uncoated or gas-shielded, offering a cleaner weld and higher deposition rates in automated or semi-automated welding applications.

Defining Welding Electrodes: Types and Characteristics

Welding electrodes are metal rods or wires coated with flux used to conduct current and create a weld pool during the welding process. Types of welding electrodes include consumable electrodes such as stick electrodes (SMAW) and non-consumable electrodes like tungsten electrodes (GTAW), each characterized by specific coatings and metals tailored for different applications and materials. Key characteristics include electrode composition, coating type, amperage range, and the ability to stabilize the arc, affect penetration depth, and control slag formation.

What is Welding Wire? Types and Applications

Welding wire is a continuous wire used as filler metal in various welding processes, primarily in Gas Metal Arc Welding (GMAW) and Flux-Cored Arc Welding (FCAW). Types of welding wire include solid wire for MIG welding, flux-cored wire for FCAW, and metal-cored wire, each designed for specific applications such as automotive manufacturing, structural steel fabrication, and pipe welding. Welding wire offers efficient material deposition, consistent weld quality, and is selected based on factors like base metal compatibility, welding position, and desired mechanical properties.

Key Differences Between Welding Electrodes and Welding Wire

Welding electrodes consist of a metal core covered with flux, designed for use in shielded metal arc welding (SMAW), while welding wire is a continuous, uncoated metal spool utilized mainly in gas metal arc welding (GMAW). Electrodes provide protective slag that shields the weld from contamination, whereas welding wire relies on an external shielding gas to prevent oxidation during welding. The choice between electrodes and wire depends on factors such as welding process type, material compatibility, and specific project requirements.

Material Compatibility: Choosing Between Electrode and Wire

Welding electrodes offer better compatibility with a wide range of materials, including cast iron, stainless steel, and aluminum, due to their flux coatings that stabilize the arc and improve slag removal. Welding wire, commonly used in MIG and TIG processes, excels with thinner metals and provides cleaner welds on materials like carbon steel and some non-ferrous metals but may struggle with heavily rusted or dirty surfaces. Your choice between electrode and wire depends on the specific material you're working with and the welding process suited for optimal adhesion and strength.

Performance Comparison: Strength, Durability, and Quality

Welding electrode and welding wire differ significantly in performance, with welding wire often providing superior strength and consistently high-quality welds due to its continuous feed process. Electrodes offer durability in applications requiring manual control and are preferred for maintenance or repair jobs where precision is key. Your selection will influence the overall weld quality, as welding wire excels in uniformity and speed, while electrodes provide versatility and ease of use in varied environments.

Applications and Industry Usage

Welding electrodes are primarily used in shielded metal arc welding (SMAW) for repair work, construction, and pipeline projects due to their versatility and ability to weld thicker materials. Welding wires, commonly employed in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW), are preferred in automotive manufacturing, shipbuilding, and fabrication industries for high-speed and continuous welding applications. The choice between electrodes and wires depends on factors such as material type, desired weld quality, and production efficiency in sectors like aerospace, oil and gas, and heavy machinery.

Cost Analysis: Electrode vs. Welding Wire

Welding electrodes generally have a higher initial cost per unit compared to welding wire but can offer better efficiency in specific applications, reducing overall expenses. Welding wire typically provides cost savings through continuous feed mechanisms and less downtime, making it economical for high-volume or automated welding processes. Material type, coating, and welding technique significantly impact total cost, necessitating a detailed analysis based on project requirements and production scale.

Advantages and Disadvantages of Each Option

Welding electrodes offer stable arc control and are ideal for outdoor use due to their flux coating, which protects the weld from contamination, but they typically produce more smoke and require frequent replacement. Welding wires provide continuous feeding for faster welding speeds and cleaner welds with less slag, suited for automated processes and indoor environments, yet they require specialized equipment and shielding gas for effective use. Your choice depends on your specific welding needs, balancing portability and ease with efficiency and weld quality.

Selecting the Right Filler Material for Your Project

Selecting the right filler material for your project involves understanding the differences between welding electrodes and welding wire. Welding electrodes are coated rods used in shielded metal arc welding (SMAW), offering better slag protection and positional versatility, while welding wire feeds continuously in processes like MIG/MAG welding, providing higher deposition rates and cleaner welds. Your choice depends on factors such as base metal type, welding position, and desired weld quality, ensuring efficient performance and strong joint integrity.

Welding electrode vs welding wire Infographic

libmatt.com

libmatt.com