Coiled tubing offers enhanced flexibility and continuous length without welds, making it ideal for complex well interventions and reducing the risk of leaks compared to straight tubing. Your choice depends on project requirements, as straight tubing provides greater strength and is better suited for high-pressure applications where rigidity is essential.

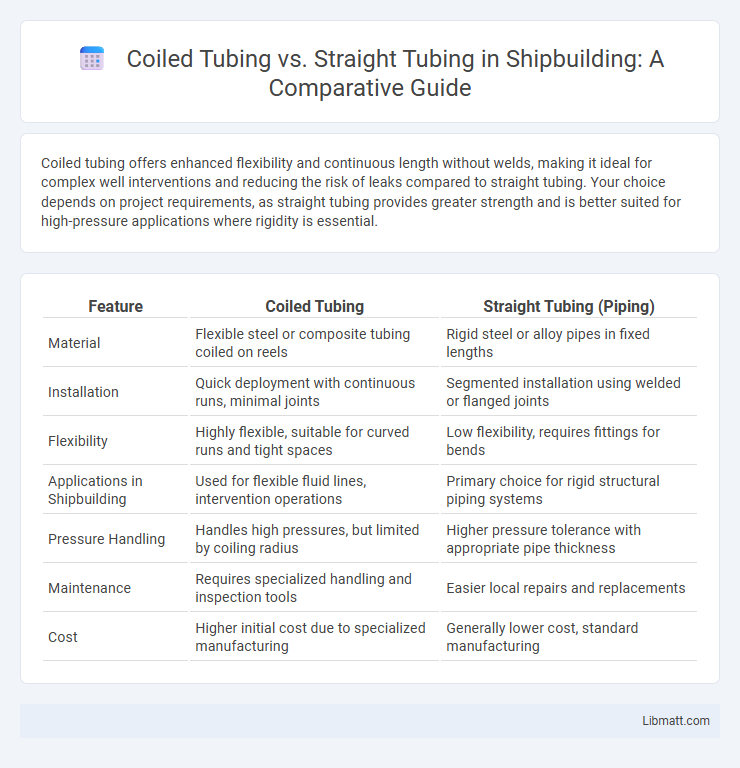

Table of Comparison

| Feature | Coiled Tubing | Straight Tubing (Piping) |

|---|---|---|

| Material | Flexible steel or composite tubing coiled on reels | Rigid steel or alloy pipes in fixed lengths |

| Installation | Quick deployment with continuous runs, minimal joints | Segmented installation using welded or flanged joints |

| Flexibility | Highly flexible, suitable for curved runs and tight spaces | Low flexibility, requires fittings for bends |

| Applications in Shipbuilding | Used for flexible fluid lines, intervention operations | Primary choice for rigid structural piping systems |

| Pressure Handling | Handles high pressures, but limited by coiling radius | Higher pressure tolerance with appropriate pipe thickness |

| Maintenance | Requires specialized handling and inspection tools | Easier local repairs and replacements |

| Cost | Higher initial cost due to specialized manufacturing | Generally lower cost, standard manufacturing |

Introduction to Coiled Tubing and Straight Tubing

Coiled tubing consists of continuous lengths of flexible steel pipe wound on a spool, commonly used for well intervention and drilling operations in the oil and gas industry due to its ability to be deployed without joint connections. Straight tubing, or jointed tubing, is composed of individual rigid pipe sections connected by threaded or welded joints, typically utilized in traditional drilling and production systems where structural integrity and high-pressure resistance are critical. The choice between coiled tubing and straight tubing depends on application requirements, such as flexibility, deployment speed, strength, and operational environment.

Key Differences Between Coiled and Straight Tubing

Coiled tubing is continuous, flexible pipe wound on a reel, allowing for easy transport and deployment in drilling and well intervention, while straight tubing consists of rigid, prefabricated sections joined together. Coiled tubing offers superior flexibility and faster installation, reducing downtime in operations, whereas straight tubing provides higher strength and durability for high-pressure applications. Your choice depends on the specific operational needs, such as well complexity and pressure requirements, balancing efficiency with mechanical performance.

Material and Manufacturing Process Comparison

Coiled tubing is typically made from high-strength steel alloys such as carbon steel or stainless steel, manufactured through a continuous bending and spooling process that imparts flexibility and resilience. In contrast, straight tubing is often produced using precision extrusion or seamless pipe manufacturing methods that emphasize uniform diameter and structural rigidity, commonly utilizing materials like carbon steel or alloy steel. The continuous manufacturing of coiled tubing enables longer, joint-free lengths, while straight tubing segments require welding or coupling, affecting installation speed and joint integrity.

Installation Procedures: Coiled vs Straight Tubing

Coiled tubing installation requires specialized reel systems and continuous deployment, minimizing the number of connections and reducing installation time compared to straight tubing, which involves linking multiple rigid pipe sections with threaded or welded joints. Coiled tubing offers enhanced flexibility in navigating complex wellbore trajectories, allowing for efficient deployment in deviated or horizontal wells, whereas straight tubing demands precise alignment and extensive fittings to accommodate wellbore deviations. The continuous length of coiled tubing reduces leak potential and improves overall system integrity, contrasting with straight tubing, which often requires additional inspection and maintenance at connection points.

Flexibility and Handling Advantages

Coiled tubing offers superior flexibility compared to straight tubing, enabling easier navigation through complex wellbore geometries and reducing the risk of buckling or damage during installation. Its continuous length eliminates joints, enhancing handling efficiency and minimizing leak points, which is crucial for maintaining well integrity. Straight tubing, while easier to manufacture and connect in segments, lacks the adaptability of coiled tubing in confined or curved spaces, making coiled tubing the preferred choice for challenging operational environments.

Pressure Ratings and Performance

Coiled tubing offers superior pressure ratings compared to straight tubing due to its continuous, seamless design that minimizes welds and potential weak points. Its flexibility allows for enhanced performance in dynamic well conditions, such as pressure surges and temperature fluctuations, maintaining integrity where straight tubing may fail. Straight tubing, while generally easier to inspect and install, often has lower pressure tolerance and reduced adaptability in complex operational environments.

Maintenance and Repair Considerations

Coiled tubing offers easier maintenance due to its continuous length without seams, reducing potential leak points and simplifying inspections. Straight tubing requires more frequent joint inspections and welding repairs, increasing downtime and maintenance complexity. Your choice between coiled and straight tubing impacts repair efficiency and long-term maintenance costs in piping systems.

Common Applications in the Oil and Gas Industry

Coiled tubing is predominantly used for well intervention, drilling, and acidizing due to its flexibility and ability to navigate complex well trajectories. Straight tubing, or jointed pipe, serves as the primary conduit for production and transportation of hydrocarbons within the oil and gas extraction process, offering higher structural integrity for long vertical or horizontal wells. The choice between coiled and straight tubing hinges on operational demands such as well depth, pressure conditions, and the specific intervention or production task at hand.

Cost Analysis: Initial and Long-Term Expenses

Coiled tubing typically involves lower initial installation costs due to reduced labor and faster deployment compared to straight tubing, which requires more extensive welding and threading. Long-term expenses for coiled tubing are generally higher because of maintenance needs and potential replacement from fatigue damage, while straight tubing offers greater durability and lower maintenance costs over time. Evaluating total cost of ownership favors coiled tubing for short-term projects and straight tubing for long-term pipeline infrastructure.

Choosing the Right Tubing Solution for Your Project

Selecting between coiled tubing and straight tubing depends on project requirements such as flexibility, installation speed, and space constraints. Coiled tubing offers continuous length and ease of deployment in tight or curved spaces, reducing connection points and potential leak risks. Straight tubing provides higher strength and is better suited for rigid, high-pressure applications where precise measurements and segment replacements are essential.

Coiled tubing vs straight tubing (piping) Infographic

libmatt.com

libmatt.com