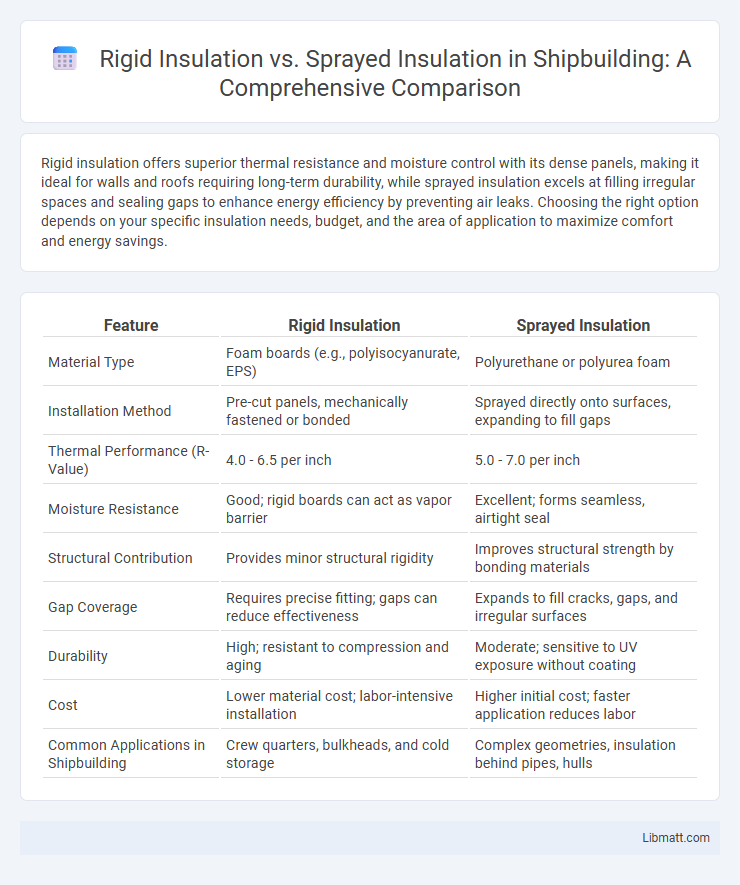

Rigid insulation offers superior thermal resistance and moisture control with its dense panels, making it ideal for walls and roofs requiring long-term durability, while sprayed insulation excels at filling irregular spaces and sealing gaps to enhance energy efficiency by preventing air leaks. Choosing the right option depends on your specific insulation needs, budget, and the area of application to maximize comfort and energy savings.

Table of Comparison

| Feature | Rigid Insulation | Sprayed Insulation |

|---|---|---|

| Material Type | Foam boards (e.g., polyisocyanurate, EPS) | Polyurethane or polyurea foam |

| Installation Method | Pre-cut panels, mechanically fastened or bonded | Sprayed directly onto surfaces, expanding to fill gaps |

| Thermal Performance (R-Value) | 4.0 - 6.5 per inch | 5.0 - 7.0 per inch |

| Moisture Resistance | Good; rigid boards can act as vapor barrier | Excellent; forms seamless, airtight seal |

| Structural Contribution | Provides minor structural rigidity | Improves structural strength by bonding materials |

| Gap Coverage | Requires precise fitting; gaps can reduce effectiveness | Expands to fill cracks, gaps, and irregular surfaces |

| Durability | High; resistant to compression and aging | Moderate; sensitive to UV exposure without coating |

| Cost | Lower material cost; labor-intensive installation | Higher initial cost; faster application reduces labor |

| Common Applications in Shipbuilding | Crew quarters, bulkheads, and cold storage | Complex geometries, insulation behind pipes, hulls |

Introduction to Rigid and Sprayed Insulation

Rigid insulation consists of solid panels made from materials like polyisocyanurate, expanded polystyrene, or extruded polystyrene, offering high thermal resistance and structural support for walls and roofs. Sprayed insulation, commonly spray foam insulation, involves applying polyurethane foam that expands and seals gaps, providing superior air sealing and moisture resistance. Both types serve distinct purposes in energy efficiency and building envelope protection, with rigid boards favored for continuous insulation and sprayed foam preferred for cavities and irregular surfaces.

Key Differences Between Rigid and Sprayed Insulation

Rigid insulation offers high compressive strength and consistent thermal resistance, making it ideal for walls, roofs, and foundations, while sprayed insulation provides superior air sealing and fills irregular gaps effectively, enhancing energy efficiency. Rigid insulation materials include foam boards like polyisocyanurate and extruded polystyrene, whereas sprayed insulation typically involves polyurethane or cellulose foam that expands on application. Installation of rigid insulation is generally easier and less labor-intensive, but sprayed insulation excels in reducing air leakage and moisture infiltration due to its seamless application.

Material Composition and Types

Rigid insulation typically consists of polystyrene (EPS or XPS), polyisocyanurate (polyiso), or polyurethane foam, offering high compressive strength and moisture resistance. Sprayed insulation is primarily made from polyurethane or cellulose, applied as a foam or loose-fill, conforming to irregular spaces and providing excellent air sealing properties. Both types vary in thermal resistance (R-value), with polyiso offering the highest R-value per inch in rigid boards, while sprayed polyurethane foam provides superior expansion and adhesion characteristics.

Installation Process Overview

Rigid insulation installation involves precisely cutting and fitting large, firm panels between studs or over surfaces, providing a straightforward and fast process with minimal settling or shrinkage. Sprayed insulation requires specialized equipment to evenly apply expanding foam into cavities, creating an air-tight seal and filling irregular spaces effectively but necessitating proper ventilation and curing time. Both methods demand careful handling to maintain thermal performance, but sprayed insulation typically offers superior adhesion and seamless coverage in complex structures.

Thermal Performance Comparison

Rigid insulation offers a consistent R-value per inch, typically ranging from 4 to 6, making it highly effective for reducing heat transfer in walls and roofs. Sprayed insulation, such as spray foam, provides an R-value between 3.5 and 6.5 per inch and excels by expanding to fill gaps and air leaks, enhancing overall thermal performance. Your choice should consider factors like installation area, air sealing needs, and long-term energy savings to maximize insulation effectiveness.

Moisture Resistance and Air Sealing

Rigid insulation offers superior moisture resistance due to its dense, closed-cell structure that prevents water absorption and maintains thermal efficiency in damp conditions. Sprayed insulation excels at air sealing by expanding to fill gaps and cracks, creating a continuous barrier that reduces drafts and energy loss. Choosing the right insulation for your project ensures optimal moisture control or air sealing based on your building's specific needs.

Cost Analysis: Initial and Long-term

Rigid insulation generally involves higher initial costs due to material and installation expenses but offers superior long-term energy savings through consistent thermal resistance and durability. Sprayed insulation usually requires lower upfront investment, yet may incur higher maintenance or replacement costs over time due to potential settling or moisture issues. Evaluating your project's budget and energy efficiency goals will help determine the most cost-effective insulation solution.

Environmental Impact and Sustainability

Rigid insulation typically has a lower environmental impact due to its longer lifespan and high thermal resistance, reducing energy consumption over time. Sprayed insulation, often made from polyurethane or cellulose, offers better air sealing properties but may release volatile organic compounds (VOCs) during application, affecting indoor air quality. Choosing materials with recycled content and low global warming potential (GWP) enhances sustainability for both insulation types.

Best Applications for Each Insulation Type

Rigid insulation is ideal for exterior walls, roofs, and foundations where a continuous thermal barrier is needed to reduce heat transfer and improve energy efficiency. Sprayed insulation excels in irregularly shaped areas, attics, wall cavities, and hard-to-reach spaces by expanding upon application to fill gaps and prevent air leaks. Choosing the right insulation depends on the specific structural needs, desired R-value, and whether moisture resistance or ease of installation is prioritized.

Choosing the Right Insulation for Your Project

Rigid insulation offers high thermal resistance and moisture durability, making it ideal for basements, foundations, and exterior walls where consistent performance is crucial. Sprayed insulation, such as spray foam, excels in sealing irregular spaces and providing superior air sealing and soundproofing, suitable for attics and complex cavities. Selecting between rigid and sprayed insulation depends on project-specific factors like climate, building design, budget, and desired energy efficiency outcomes.

Rigid insulation vs sprayed insulation Infographic

libmatt.com

libmatt.com