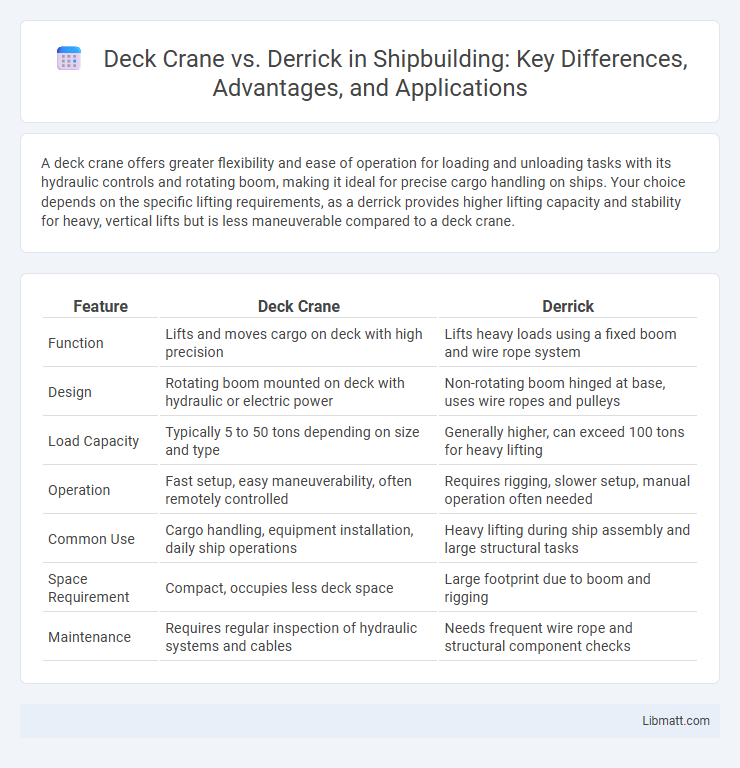

A deck crane offers greater flexibility and ease of operation for loading and unloading tasks with its hydraulic controls and rotating boom, making it ideal for precise cargo handling on ships. Your choice depends on the specific lifting requirements, as a derrick provides higher lifting capacity and stability for heavy, vertical lifts but is less maneuverable compared to a deck crane.

Table of Comparison

| Feature | Deck Crane | Derrick |

|---|---|---|

| Function | Lifts and moves cargo on deck with high precision | Lifts heavy loads using a fixed boom and wire rope system |

| Design | Rotating boom mounted on deck with hydraulic or electric power | Non-rotating boom hinged at base, uses wire ropes and pulleys |

| Load Capacity | Typically 5 to 50 tons depending on size and type | Generally higher, can exceed 100 tons for heavy lifting |

| Operation | Fast setup, easy maneuverability, often remotely controlled | Requires rigging, slower setup, manual operation often needed |

| Common Use | Cargo handling, equipment installation, daily ship operations | Heavy lifting during ship assembly and large structural tasks |

| Space Requirement | Compact, occupies less deck space | Large footprint due to boom and rigging |

| Maintenance | Requires regular inspection of hydraulic systems and cables | Needs frequent wire rope and structural component checks |

Introduction to Deck Cranes and Derricks

Deck cranes and derricks are essential lifting devices used on ships and offshore platforms to handle heavy loads and cargo. Deck cranes are typically designed with a rotating boom and hydraulic controls, offering flexible movement and precise load placement. Derricks consist of a fixed mast and a boom controlled by wire ropes, providing robust lifting capacity but less maneuverability, making them suitable for specific operations in marine environments.

Key Differences Between Deck Cranes and Derricks

Deck cranes feature a rotating boom mounted on a ship's deck, enabling versatile cargo handling with increased reach and maneuverability. Derricks rely on fixed or pivoting masts with cables to lift heavy loads, offering simpler construction but limited movement compared to deck cranes. The key differences involve operational flexibility, range of motion, and installation complexity, with deck cranes favored for dynamic loading tasks and derricks suited for heavy-duty lifting in constrained spaces.

Structural Design and Components

Deck cranes feature a robust, pivoting boom mounted on a rotating base that provides versatile lifting within a wide operational radius, supported by hydraulic or electric winches for load handling. Derricks consist of a fixed mast with guy wires or stays for stability, equipped with a boom or a fixed jib, relying on wire ropes and block-and-tackle systems to lift heavy loads vertically or at limited angles. The structural design of deck cranes emphasizes mobility and flexibility, while derricks prioritize simplicity and high load capacity with a focus on secure anchoring and minimal moving parts.

Lifting Capacity and Performance

Deck cranes offer higher lifting capacities than derricks, often ranging from several tons to over 100 tons, making them ideal for handling heavy loads swiftly and efficiently. Derricks provide more precise and stable lifting performance in confined spaces due to their fixed boom structure and simpler mechanical design. Your choice depends on the required load capacity and operational environment, with deck cranes excelling in heavy-duty, versatile tasks and derricks suited for lighter, specialized lifting needs.

Operational Flexibility and Versatility

Deck cranes offer high operational flexibility and versatility with their hydraulic or electric systems, enabling precise load handling and rapid movement in confined spaces. Derricks provide robust lifting capacity and extended reach, ideal for heavy-duty tasks but with more limited maneuverability compared to deck cranes. The choice between deck cranes and derricks depends on the specific operational requirements, such as load size, workspace constraints, and the need for quick setup or repositioning.

Safety Features and Considerations

Deck cranes incorporate advanced safety features such as overload protection systems, emergency stop controls, and anti-collision sensors to minimize operational hazards. Derricks rely on robust structural design and manual safety checks, but lack many automated safety mechanisms found in modern deck cranes. Ensuring your equipment has up-to-date safety certifications and thorough operator training is crucial for preventing accidents during lifting operations.

Typical Applications in Maritime and Offshore Industries

Deck cranes are commonly used for cargo handling, container loading, and unloading on various types of vessels, including container ships, bulk carriers, and offshore supply vessels due to their ease of operation and efficient lifting capabilities. Derricks, featuring a fixed mast and a boom pivoted at the base, are preferred in offshore platforms and oil rigs for heavy lifting tasks such as installing equipment, handling drilling components, and maintenance operations in restricted deck spaces. Both systems play crucial roles in maritime and offshore logistics, with deck cranes offering versatility and speed, while derricks provide stability and capacity for heavy, stationary lifts.

Maintenance and Lifespan Comparison

Deck cranes typically require less frequent maintenance compared to derricks due to their more modern hydraulic systems and enclosed components, which protect against corrosion and wear. Derricks, with their simpler mechanical design, demand regular inspection of wire ropes, pulleys, and structural integrity to prevent failures, often resulting in shorter operational lifespans if not meticulously maintained. Your choice between a deck crane and a derrick should consider the balance between maintenance schedules and the expected durability to optimize long-term performance and safety.

Cost Implications: Initial Investment and Operating Cost

Deck cranes typically involve a higher initial investment due to advanced technology and automation features, while derricks usually require lower upfront costs but may need more manual labor. Operating costs for deck cranes are generally reduced by efficient fuel consumption and lower maintenance needs, whereas derricks often incur higher ongoing expenses tied to labor and mechanical wear. Evaluating total cost of ownership across the equipment's lifespan is crucial for selecting between the higher-capacity deck crane and the more economical derrick.

Choosing the Right Equipment: Deck Crane or Derrick?

Selecting between a deck crane and a derrick depends on the specific operational needs and spatial constraints of the vessel. Deck cranes offer greater flexibility and faster load handling with easy rotation and outreach capabilities, ideal for dynamic cargo operations. Derricks provide robust lifting capacity and stability for heavy-duty tasks but require more deck space and complex rigging, making them suitable for fixed or repetitive lifting jobs.

Deck crane vs derrick Infographic

libmatt.com

libmatt.com