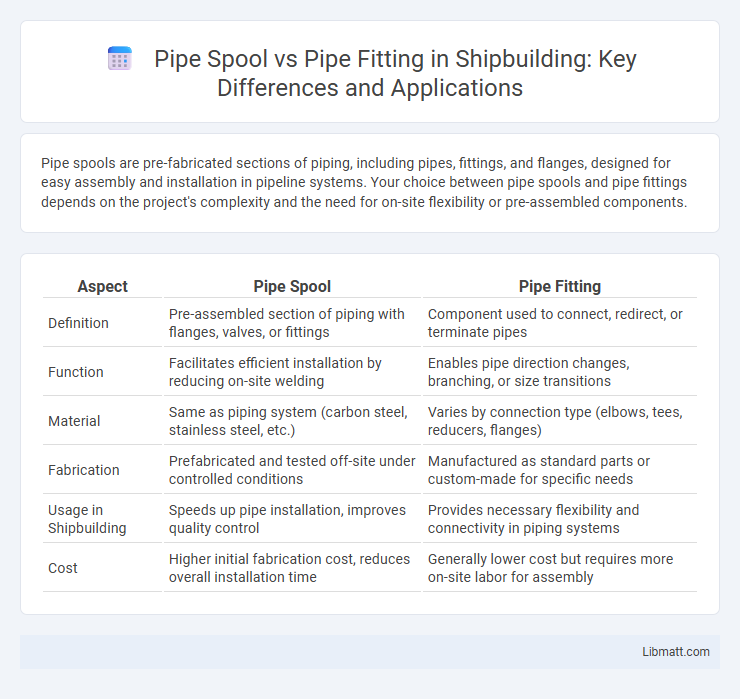

Pipe spools are pre-fabricated sections of piping, including pipes, fittings, and flanges, designed for easy assembly and installation in pipeline systems. Your choice between pipe spools and pipe fittings depends on the project's complexity and the need for on-site flexibility or pre-assembled components.

Table of Comparison

| Aspect | Pipe Spool | Pipe Fitting |

|---|---|---|

| Definition | Pre-assembled section of piping with flanges, valves, or fittings | Component used to connect, redirect, or terminate pipes |

| Function | Facilitates efficient installation by reducing on-site welding | Enables pipe direction changes, branching, or size transitions |

| Material | Same as piping system (carbon steel, stainless steel, etc.) | Varies by connection type (elbows, tees, reducers, flanges) |

| Fabrication | Prefabricated and tested off-site under controlled conditions | Manufactured as standard parts or custom-made for specific needs |

| Usage in Shipbuilding | Speeds up pipe installation, improves quality control | Provides necessary flexibility and connectivity in piping systems |

| Cost | Higher initial fabrication cost, reduces overall installation time | Generally lower cost but requires more on-site labor for assembly |

Introduction to Pipe Spools and Pipe Fittings

Pipe spools consist of pre-fabricated sections of piping with welded or flanged ends designed for easy installation in industrial piping systems, offering precise length and configuration to minimize on-site welding. Pipe fittings, on the other hand, are individual components like elbows, tees, reducers, and couplings used to connect, redirect, or control the flow within piping networks. Understanding the distinction between pipe spools and pipe fittings is essential for efficient pipeline design, construction, and maintenance in industries such as oil and gas, petrochemical, and manufacturing.

Definition and Function of Pipe Spools

Pipe spools are pre-fabricated sections of piping, consisting of pipes, flanges, and fittings, assembled and welded together in a controlled environment before being installed on-site. They function to simplify and speed up the construction and installation process by minimizing on-site welding and reducing potential errors. Your project's efficiency depends on accurately designed pipe spools that fit seamlessly within the overall piping system, ensuring reliable fluid or gas flow.

Overview and Purpose of Pipe Fittings

Pipe fittings are components used to connect, control, or change the direction of pipes within a piping system, playing a critical role in ensuring proper flow and system integrity. Unlike pipe spools, which are pre-fabricated pipe sections assembled for quicker installation, pipe fittings like elbows, tees, reducers, and couplings provide flexibility and customization to accommodate system layout and design changes. Your piping infrastructure relies on precise pipe fittings to maintain seamless connections and adapt to varying operational requirements.

Key Differences Between Pipe Spools and Pipe Fittings

Pipe spools are prefabricated sections of piping that include necessary joints and fittings, designed for easy installation and reducing onsite labor, while pipe fittings are individual components such as elbows, tees, and reducers used to connect and control the direction of pipes. The key differences lie in their purpose and application: pipe spools provide ready-to-install assemblies tailored for specific piping systems, whereas pipe fittings serve as modular parts facilitating system customization and flexibility. Understanding these distinctions helps you select the appropriate elements for efficient pipeline construction and maintenance.

Materials Used for Pipe Spools vs Pipe Fittings

Pipe spools are typically fabricated from carbon steel, stainless steel, or alloy materials designed for high-pressure and high-temperature applications, ensuring durability and corrosion resistance. Pipe fittings, on the other hand, are commonly made from a broader range of materials including cast iron, PVC, copper, and brass to accommodate various connection types and fluid compatibility. Understanding the material differences between pipe spools and fittings helps you select the right components for optimal performance and longevity in your piping system.

Fabrication Process: Pipe Spools vs Pipe Fittings

Pipe spools undergo a detailed fabrication process involving cutting, welding, and assembling multiple pipe segments and components into a single unit ready for installation, ensuring precise dimensions and alignment. Pipe fittings, on the other hand, are pre-manufactured components like elbows, tees, and reducers, produced in factories using casting or forging methods, then finished for immediate use in piping systems. Your understanding of these distinct fabrication methods helps optimize project planning and improve installation efficiency.

Installation Methods: Pipe Spools Compared to Pipe Fittings

Pipe spools are pre-fabricated sections of piping that are assembled off-site, allowing for faster and more accurate installation compared to pipe fittings, which require on-site cutting, welding, and alignment. The prefabrication of pipe spools reduces on-site labor costs and minimizes installation errors, improving overall project efficiency and safety. Pipe fittings demand skilled labor for precise joint connections and are typically used for changes in pipe direction, size, or branching within complex piping systems.

Common Applications of Pipe Spools and Pipe Fittings

Pipe spools are commonly used in industrial piping systems for prefabricated, modular sections allowing for quick installation and maintenance in oil and gas, chemical plants, and power generation facilities. Pipe fittings, including elbows, tees, and reducers, are essential for changing flow direction, branching pipelines, and connecting pipes of different sizes in plumbing, HVAC, and water supply systems. Both components are integral in constructing efficient, durable piping networks across various sectors.

Advantages and Disadvantages of Pipe Spools vs Fittings

Pipe spools offer precise factory fabrication, reducing onsite labor and minimizing installation time, which enhances quality control and reduces errors. However, they can be less flexible for modifications once installed and require accurate upfront engineering. Pipe fittings allow easier adjustments and field adaptability but may increase installation time and potential leakage points due to numerous joints.

Choosing Between Pipe Spools and Pipe Fittings in Your Project

Selecting between pipe spools and pipe fittings hinges on project requirements such as installation speed, customization, and cost. Pipe spools offer prefabricated, precise segments that reduce onsite labor and errors, ideal for complex or large-scale piping systems. In contrast, pipe fittings provide flexibility for adjustments and repairs, making them suitable for projects needing on-the-spot modifications or smaller installations.

Pipe spool vs pipe fitting Infographic

libmatt.com

libmatt.com