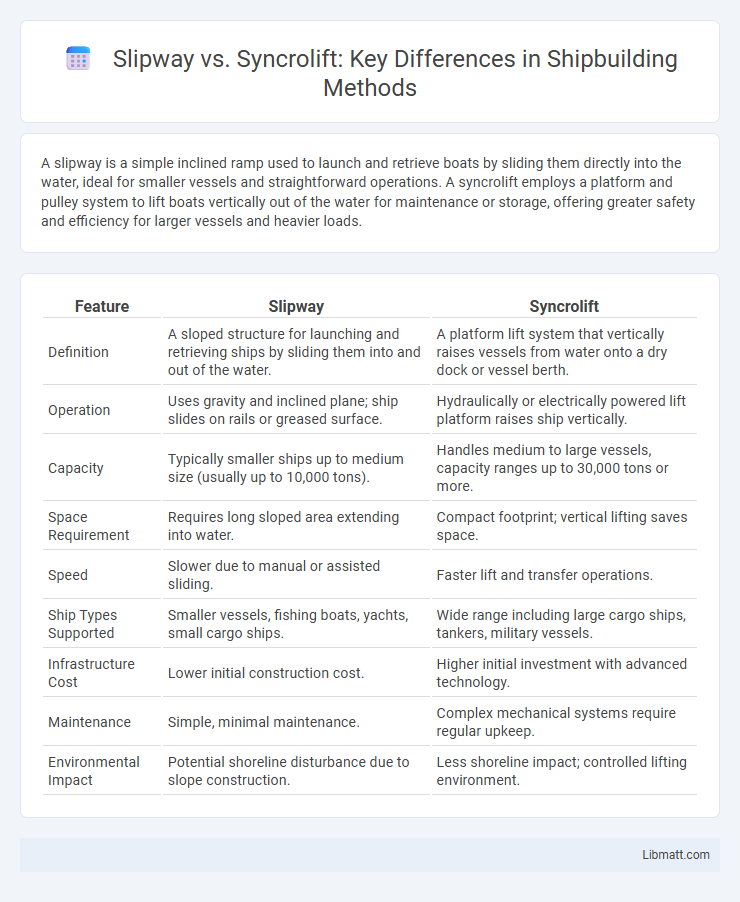

A slipway is a simple inclined ramp used to launch and retrieve boats by sliding them directly into the water, ideal for smaller vessels and straightforward operations. A syncrolift employs a platform and pulley system to lift boats vertically out of the water for maintenance or storage, offering greater safety and efficiency for larger vessels and heavier loads.

Table of Comparison

| Feature | Slipway | Syncrolift |

|---|---|---|

| Definition | A sloped structure for launching and retrieving ships by sliding them into and out of the water. | A platform lift system that vertically raises vessels from water onto a dry dock or vessel berth. |

| Operation | Uses gravity and inclined plane; ship slides on rails or greased surface. | Hydraulically or electrically powered lift platform raises ship vertically. |

| Capacity | Typically smaller ships up to medium size (usually up to 10,000 tons). | Handles medium to large vessels, capacity ranges up to 30,000 tons or more. |

| Space Requirement | Requires long sloped area extending into water. | Compact footprint; vertical lifting saves space. |

| Speed | Slower due to manual or assisted sliding. | Faster lift and transfer operations. |

| Ship Types Supported | Smaller vessels, fishing boats, yachts, small cargo ships. | Wide range including large cargo ships, tankers, military vessels. |

| Infrastructure Cost | Lower initial construction cost. | Higher initial investment with advanced technology. |

| Maintenance | Simple, minimal maintenance. | Complex mechanical systems require regular upkeep. |

| Environmental Impact | Potential shoreline disturbance due to slope construction. | Less shoreline impact; controlled lifting environment. |

Introduction to Slipways and Syncrolifts

Slipways are inclined ramps used for launching and retrieving vessels by allowing boats to slide into the water, typically powered by gravity or winches. Syncrolifts are advanced ship hoisting platforms that lift vessels vertically for maintenance or repair, providing precise control and safety. Your choice between a slipway and a syncrolift depends on the size of the vessel and the operational requirements of the dockyard.

Historical Development of Ship Lifting Methods

Slipways, one of the oldest ship lifting methods, originated in the early maritime industry as inclined planes allowing vessels to slide into the water for construction and repair. The 20th century saw the emergence of the syncrolift, a technologically advanced system introducing synchronized lifting platforms, significantly enhancing efficiency and safety in shipyard operations. This evolution from slipway to syncrolift reflects the maritime industry's shift towards mechanization and precision in vessel maintenance.

How Slipways Work: An Overview

Slipways operate by using a sloped ramp extending into the water, allowing vessels to be floated onto a cradle or wheeled trolley that slides up or down the inclined surface for launching or retrieval. This simple mechanical system relies on gravity and manual or powered winches to move boats securely between water and land. Slipways are ideal for smaller vessels and shipyards requiring cost-effective and straightforward access to the waterline.

Understanding the Syncrolift System

The Syncrolift system utilizes a crane-like platform to lift vessels vertically from the water for maintenance and repair, offering precise control and reduced hull stress compared to traditional slipways. Unlike slipways, which rely on inclined ramps for launching and retrieving ships, Syncrolifts provide a flexible and efficient solution for accommodating various vessel sizes. This system's advanced design enhances safety, turnaround time, and operational efficiency in shipyards worldwide.

Comparative Cost Analysis

Slipways generally involve lower initial capital expenditure compared to Syncrolifts, as their construction relies on simpler, traditional ramp structures. Syncrolifts require higher upfront investment due to advanced mechanical and hydraulic systems but offer greater operational efficiency and vessel handling flexibility. Long-term costs may favor Syncrolifts by reducing labor and downtime, making them economically advantageous for frequent and large-scale ship servicing operations.

Efficiency and Turnaround Time

Slipways offer a straightforward, gravity-based method for launching and retrieving vessels, resulting in quick turnaround times for smaller boats due to minimal mechanical complexity. Syncrolifts provide higher efficiency for larger vessels by using a platform that lifts ships vertically out of the water, allowing simultaneous maintenance and reducing wait times in busy shipyards. Your choice depends on vessel size and operational demands, with syncrolifts generally offering faster handling for extensive refits and repairs.

Safety and Environmental Considerations

Slipways provide a straightforward method for vessel launching and retrieval but pose higher risks of slips and environmental contamination due to potential oil and fuel runoff into nearby water. Syncrolifts offer enhanced safety by using controlled lifting mechanisms that minimize the risk of accidents and structural damage during operations. Environmentally, syncrolifts reduce pollution risk through contained drainage systems and careful handling, making them preferable for eco-sensitive marina or shipyard settings.

Suitability for Different Vessel Types

Slipways excel in accommodating smaller vessels such as fishing boats, yachts, and small commercial craft due to their simpler, cost-effective design and ease of use for launching and retrieval. Syncrolifts are better suited for larger vessels including naval ships, ferries, and sizable commercial vessels, providing precise lifting and stable transfer from water to dry dock for maintenance and repairs. The choice depends on vessel size, weight capacity, and operational requirements, with slipways catering to lighter loads and syncrolifts handling heavy-duty maritime needs.

Maintenance and Operational Requirements

Slipways require extensive space and labor-intensive maintenance due to their exposure to tidal conditions and constant water contact, leading to corrosion and biofouling challenges. Syncrolifts feature advanced lifting platforms with minimal environmental exposure, reducing the frequency and intensity of maintenance tasks while enabling quicker and more efficient vessel retrieval and launching. Operationally, slipways depend heavily on tidal windows and manual controls, whereas syncrolifts offer precise mechanical operation, enhancing safety and reducing downtime during maintenance cycles.

Choosing Between Slipway and Syncrolift: Key Factors

Choosing between a slipway and a syncrolift depends on your vessel size, dock space availability, and operational efficiency needs. Slipways offer cost-effective, gravity-based launch and recovery ideal for smaller boats and limited budgets, while syncrolifts provide mechanized lifting suitable for larger vessels and frequent handling. Your decision should weigh maintenance costs, turnaround times, and infrastructure requirements to optimize marine service operations.

Slipway vs syncrolift Infographic

libmatt.com

libmatt.com