Plate bending shapes metal plates by applying force along a straight axis to create specific angles or forms, offering precise control for angular bends. Plate rolling, on the other hand, continuously curves your metal sheets into cylindrical or conical shapes by passing them through rotating rollers, ideal for producing rounded profiles efficiently.

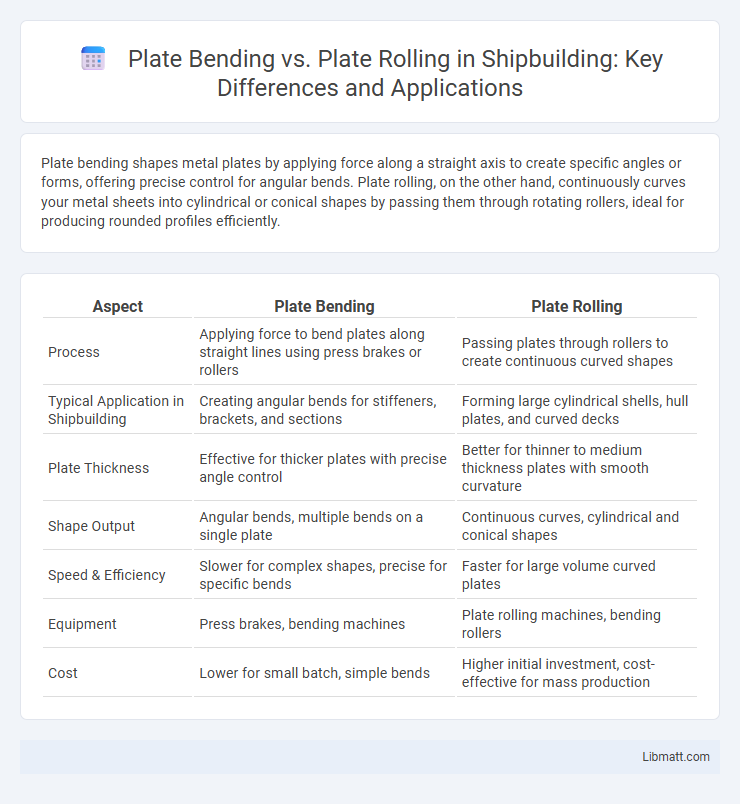

Table of Comparison

| Aspect | Plate Bending | Plate Rolling |

|---|---|---|

| Process | Applying force to bend plates along straight lines using press brakes or rollers | Passing plates through rollers to create continuous curved shapes |

| Typical Application in Shipbuilding | Creating angular bends for stiffeners, brackets, and sections | Forming large cylindrical shells, hull plates, and curved decks |

| Plate Thickness | Effective for thicker plates with precise angle control | Better for thinner to medium thickness plates with smooth curvature |

| Shape Output | Angular bends, multiple bends on a single plate | Continuous curves, cylindrical and conical shapes |

| Speed & Efficiency | Slower for complex shapes, precise for specific bends | Faster for large volume curved plates |

| Equipment | Press brakes, bending machines | Plate rolling machines, bending rollers |

| Cost | Lower for small batch, simple bends | Higher initial investment, cost-effective for mass production |

Introduction to Plate Bending and Plate Rolling

Plate bending involves deforming flat metal plates into curved shapes by applying force through a press brake or bending machine, commonly used for fabricating components like brackets, channels, and enclosures. Plate rolling, on the other hand, employs a series of rollers to progressively curve and shape metal plates into cylindrical or conical forms, essential for manufacturing pipes, tanks, and structural elements. Both processes are critical in metal fabrication, offering precise control over thickness, curvature, and structural integrity for various industrial applications.

Defining Plate Bending: Process and Applications

Plate bending involves deforming metal sheets using force applied by press brakes or rolls to achieve specific angles or curves, primarily for structural components and machinery parts. This process is ideal for creating precise bends in plates typically ranging from thin gauge sheets to thicker metal plates used in construction and manufacturing. Your choice of plate bending depends on factors like material thickness, bend radius, and desired angle accuracy, distinguishing it from plate rolling, which forms continuous curves or cylinders.

Understanding Plate Rolling: Techniques and Uses

Plate rolling involves passing metal plates through rollers to achieve a curved or cylindrical shape, commonly used in manufacturing tanks, pipes, and structural components. This technique allows precise control over the radius and angle of the bend, making it ideal for large-scale production where consistency is crucial. Understanding your material's thickness and tensile properties ensures optimal results and prevents defects during the rolling process.

Key Differences Between Plate Bending and Plate Rolling

Plate bending involves shaping metal plates by applying force at specific points to create angles or curves, while plate rolling continuously feeds the plate through rollers to form cylindrical shapes or curves. Plate bending is ideal for precise angles and small radius bends, whereas plate rolling is suited for producing large radius curves and cylinders. Understanding these differences helps you select the appropriate method for your metal forming requirements based on the desired shape and production volume.

Material Suitability: When to Bend vs When to Roll

Plate bending is ideal for thicker, heavier materials requiring precise angle formation, commonly used for steel plates up to several inches thick. Plate rolling suits thinner, more ductile metals like aluminum and mild steel, transforming flat sheets into smooth, curved shapes or cylinders. Choosing between bending and rolling depends on material thickness, ductility, and the final geometric requirements of the workpiece.

Equipment Required for Plate Bending and Rolling

Plate bending requires a press brake or bending machine equipped with specific tooling such as punches and dies to apply precise force, enabling accurate angular deformation of metal plates. Plate rolling involves the use of a plate rolling machine or plate bending rolls, consisting of multiple rollers that gradually curve the metal plate into cylindrical or conical shapes. The choice of equipment depends on the desired bending angle and shape complexity, with plate bending machines suitable for sharp bends and plate rolling machines ideal for smooth, continuous curves.

Accuracy and Precision: Comparing End Results

Plate bending offers higher accuracy for complex, tight-radius bends due to controlled force application, while plate rolling excels in producing uniform curves over larger surfaces with consistent precision. Your choice depends on the required end geometry: bending is preferred for precise angles and sharp corners, whereas rolling ensures smooth, continuous arcs. Understanding these differences helps optimize your fabrication process for the desired accuracy and precision.

Cost Efficiency: Plate Bending vs Plate Rolling

Plate bending generally offers greater cost efficiency for small to medium-sized projects due to lower initial equipment investment and quicker setup times, making it ideal for custom or low-volume production. Plate rolling, while requiring higher upfront costs for machinery, becomes more cost-effective in large-scale manufacturing by enabling faster processing of thicker plates and consistent cylindrical shapes. You can optimize your budget by selecting plate bending for short runs and plate rolling when high volume and uniformity are priorities.

Industry Applications of Plate Bending and Plate Rolling

Plate bending is widely used in industries requiring precise angular shapes, such as construction, shipbuilding, and heavy machinery manufacturing, where forming beams and structural components is essential. Plate rolling is crucial in producing cylindrical shapes for pipelines, tanks, and pressure vessels across oil and gas, petrochemical, and power generation sectors. Understanding your specific project needs helps determine whether plate bending or rolling best suits the manufacturing requirements for optimal structural integrity and efficiency.

Selecting the Right Method for Your Project

Selecting the right method for your project depends on factors like material thickness, desired shape, and production volume. Plate bending is ideal for creating angular bends and precise corners on thicker materials, while plate rolling excels in forming uniform cylindrical shapes and curves, especially for large or thin plates. Understanding these distinctions helps optimize efficiency, cost, and final product quality.

Plate bending vs plate rolling Infographic

libmatt.com

libmatt.com