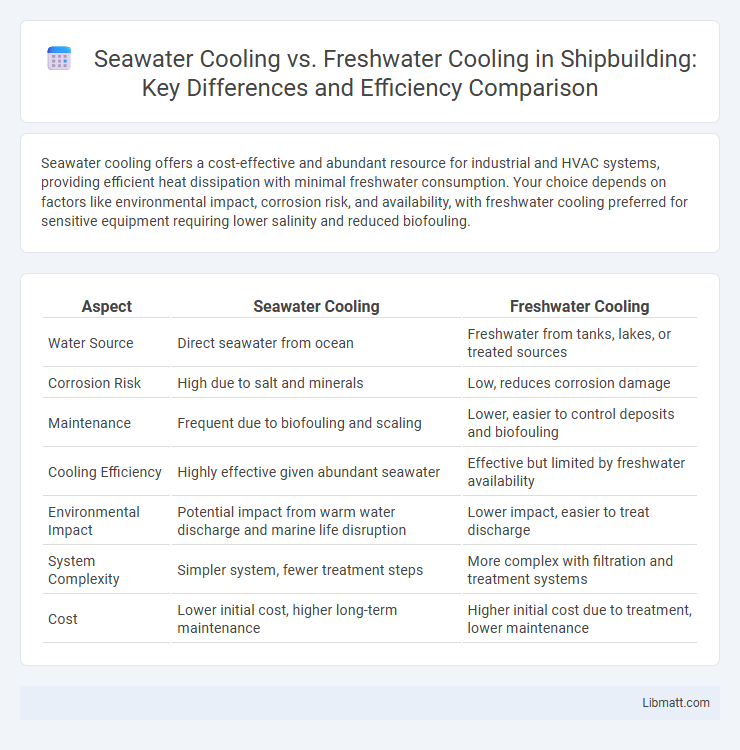

Seawater cooling offers a cost-effective and abundant resource for industrial and HVAC systems, providing efficient heat dissipation with minimal freshwater consumption. Your choice depends on factors like environmental impact, corrosion risk, and availability, with freshwater cooling preferred for sensitive equipment requiring lower salinity and reduced biofouling.

Table of Comparison

| Aspect | Seawater Cooling | Freshwater Cooling |

|---|---|---|

| Water Source | Direct seawater from ocean | Freshwater from tanks, lakes, or treated sources |

| Corrosion Risk | High due to salt and minerals | Low, reduces corrosion damage |

| Maintenance | Frequent due to biofouling and scaling | Lower, easier to control deposits and biofouling |

| Cooling Efficiency | Highly effective given abundant seawater | Effective but limited by freshwater availability |

| Environmental Impact | Potential impact from warm water discharge and marine life disruption | Lower impact, easier to treat discharge |

| System Complexity | Simpler system, fewer treatment steps | More complex with filtration and treatment systems |

| Cost | Lower initial cost, higher long-term maintenance | Higher initial cost due to treatment, lower maintenance |

Introduction to Cooling Systems

Seawater cooling systems utilize the ocean's natural thermal capacity to regulate industrial and HVAC equipment temperatures, offering abundant resource availability and reduced freshwater demand. Freshwater cooling relies on lakes, rivers, or processed water, providing controlled quality but facing limitations due to scarcity and environmental regulations. Both systems require tailored designs to optimize heat exchange efficiency and mitigate corrosion, scaling, and ecological impacts.

Overview of Seawater Cooling

Seawater cooling utilizes ocean water as a natural heat sink, offering a sustainable and efficient method for regulating temperatures in power plants, HVAC systems, and marine vessels. It reduces the reliance on freshwater resources, which is critical in regions facing freshwater scarcity. Your facility can benefit from seawater cooling by decreasing environmental impact and operational costs compared to traditional freshwater cooling methods.

Overview of Freshwater Cooling

Freshwater cooling systems utilize lakes, rivers, or treated water sources to absorb and dissipate heat from industrial processes or HVAC units, offering consistent temperature control and reduced corrosion risks compared to seawater. These systems often require less maintenance and have a lower environmental impact due to minimal salt-induced equipment wear and easier chemical treatment management. Your choice of freshwater cooling can enhance operational efficiency and infrastructure longevity in regions where freshwater availability is sufficient and environmental regulations are stringent.

Thermal Efficiency Comparison

Seawater cooling systems generally exhibit lower thermal efficiency compared to freshwater cooling due to higher corrosion rates and biofouling that reduce heat transfer effectiveness. Freshwater cooling offers superior thermal conductivity and lower scaling potential, enabling more consistent and efficient heat exchange. However, advances in materials and maintenance practices are improving seawater cooling efficiency in marine and coastal power plants.

Environmental Impact Assessment

Seawater cooling systems reduce freshwater consumption by utilizing abundant ocean resources, mitigating freshwater depletion and preserving inland ecosystems. Potential environmental impacts include marine life disruption and thermal pollution, necessitating stringent environmental impact assessments to ensure sustainable operation. Your choice between seawater and freshwater cooling should consider local ecological sensitivity, regulatory frameworks, and long-term resource availability to minimize environmental footprint.

Corrosion and Maintenance Issues

Seawater cooling systems face increased corrosion risks due to high salt content and marine organisms, requiring specialized anti-corrosion coatings and frequent maintenance to prevent equipment degradation. Freshwater cooling generally experiences lower corrosion rates, resulting in less intensive maintenance demands and longer equipment lifespan. Selecting appropriate materials and regular monitoring are essential to managing corrosion and maintenance costs in both cooling methods.

Water Availability and Sustainability

Seawater cooling leverages the vast and renewable ocean water supply, reducing dependency on limited freshwater resources and enhancing sustainability in coastal power plants and industrial facilities. Freshwater cooling, however, can strain local water supplies, especially in arid regions or during droughts, impacting ecological balance and long-term water availability. Choosing seawater cooling supports your facility's environmental goals by conserving freshwater for critical human and agricultural needs.

Cost Analysis: Installation and Operation

Seawater cooling systems typically have higher installation costs due to corrosion-resistant materials and specialized maintenance requirements, but they benefit from abundant and free cooling water sources, reducing operational expenses. Freshwater cooling generally demands lower upfront investment but incurs ongoing costs related to water procurement, treatment, and potential scarcity management. Evaluating your cooling needs involves balancing seawater's durable efficiency against freshwater's accessibility and long-term price fluctuations.

Industrial Applications and Case Studies

Seawater cooling is predominantly utilized in coastal power plants, petrochemical refineries, and desalination facilities due to its abundant availability and cost-efficiency in dissipating large heat loads. Freshwater cooling systems are preferred in inland industrial applications such as manufacturing, chemical processing, and HVAC systems, where environmental regulations limit seawater use and water quality control is critical. Case studies from nuclear power plants demonstrate seawater cooling's effectiveness in thermal regulation, while freshwater cooling showcases advantages in process stability and reduced corrosion in metal-intensive industries.

Future Trends in Cooling Technologies

Future trends in cooling technologies emphasize the adoption of seawater cooling systems due to their sustainability and reduced freshwater consumption, addressing global water scarcity challenges. Advancements in corrosion-resistant materials and energy-efficient heat exchangers enhance seawater cooling's viability in industrial and data center applications. Integration with renewable energy sources and smart cooling management systems further optimizes performance and environmental impact compared to traditional freshwater cooling methods.

Seawater cooling vs freshwater cooling Infographic

libmatt.com

libmatt.com