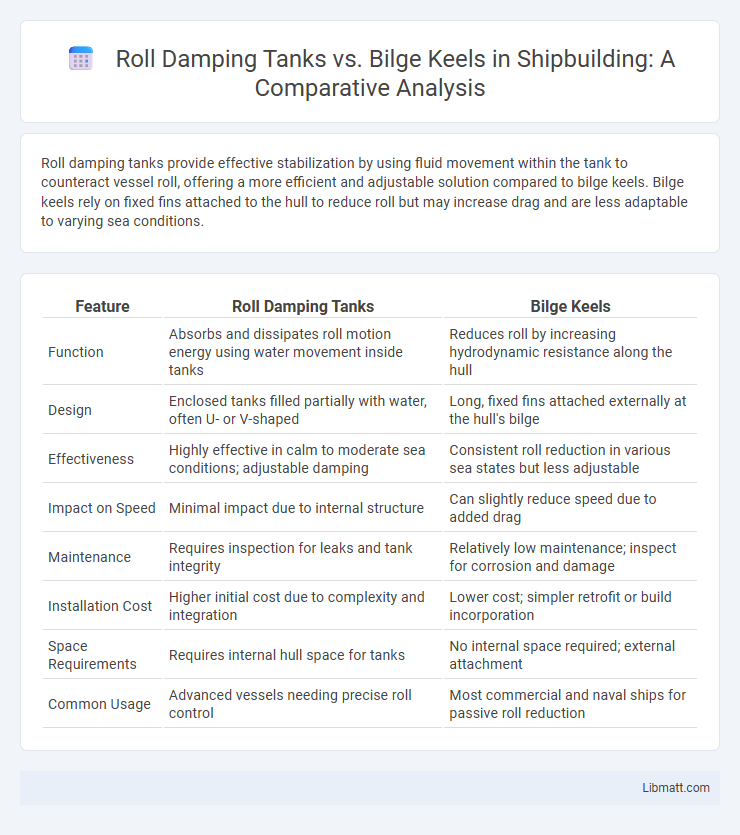

Roll damping tanks provide effective stabilization by using fluid movement within the tank to counteract vessel roll, offering a more efficient and adjustable solution compared to bilge keels. Bilge keels rely on fixed fins attached to the hull to reduce roll but may increase drag and are less adaptable to varying sea conditions.

Table of Comparison

| Feature | Roll Damping Tanks | Bilge Keels |

|---|---|---|

| Function | Absorbs and dissipates roll motion energy using water movement inside tanks | Reduces roll by increasing hydrodynamic resistance along the hull |

| Design | Enclosed tanks filled partially with water, often U- or V-shaped | Long, fixed fins attached externally at the hull's bilge |

| Effectiveness | Highly effective in calm to moderate sea conditions; adjustable damping | Consistent roll reduction in various sea states but less adjustable |

| Impact on Speed | Minimal impact due to internal structure | Can slightly reduce speed due to added drag |

| Maintenance | Requires inspection for leaks and tank integrity | Relatively low maintenance; inspect for corrosion and damage |

| Installation Cost | Higher initial cost due to complexity and integration | Lower cost; simpler retrofit or build incorporation |

| Space Requirements | Requires internal hull space for tanks | No internal space required; external attachment |

| Common Usage | Advanced vessels needing precise roll control | Most commercial and naval ships for passive roll reduction |

Introduction to Ship Roll Damping

Roll damping tanks utilize internal water movement to reduce a ship's roll motion by absorbing and dissipating energy, offering effective stabilization especially in rough sea conditions. Bilge keels, fixed external fins along the hull, increase hydrodynamic resistance to roll, providing a passive and low-maintenance solution. Your choice between roll damping tanks and bilge keels depends on factors like ship design, operational profile, and maintenance preferences.

Overview of Roll Damping Tanks

Roll damping tanks are specialized compartments integrated into a ship's hull designed to reduce rolling motion by using the movement of liquid inside to counteract the vessel's roll. Unlike bilge keels, which are external fins that increase hydrodynamic resistance, roll damping tanks leverage the fluid's inertia and sloshing effect to provide effective roll stabilization without significantly impacting speed or fuel efficiency. Your choice of roll damping tanks can enhance onboard comfort and operational safety by minimizing excessive roll in rough sea conditions.

Key Features of Bilge Keels

Bilge keels are fixed fin-like structures attached along the hull's bilge to reduce a ship's rolling motion by increasing hydrodynamic resistance. They are low-maintenance, require no internal space, and have minimal impact on vessel stability and speed while effectively damping roll in moderate sea conditions. Your choice of bilge keels ensures passive roll control without complex mechanical systems or additional weight.

Mechanisms of Roll Reduction

Roll damping tanks reduce vessel roll by using internal water movement to counteract the ship's motion, creating anti-phase waves that dissipate energy and stabilize the vessel. Bilge keels function through passive hydrodynamic resistance, increasing hull surface area to create drag and reduce rolling amplitude. Your choice between these systems depends on the required efficiency and maintenance considerations for roll reduction mechanisms.

Installation and Maintenance Considerations

Roll damping tanks require complex installation involving internal structural modifications and precise positioning to optimize hydrodynamic performance, whereas bilge keels are simpler to fit externally along the hull with minimal structural changes. Maintenance of roll damping tanks demands regular inspection for corrosion and internal fouling, often necessitating dry docking, while bilge keels typically need less frequent upkeep, mainly focusing on hull cleaning and damage inspection. Your choice between these systems should weigh the installation effort and ongoing maintenance impact on vessel downtime and operational costs.

Performance Comparison: Tanks vs. Keels

Roll damping tanks provide dynamic stabilization by counteracting ship roll through fluid movement, offering superior performance in reducing roll amplitude across a wide range of sea conditions. Bilge keels, on the other hand, are fixed appendages that passively resist roll motion, delivering consistent but less adaptable damping primarily effective at lower roll frequencies. Compared to bilge keels, roll damping tanks enhance comfort and operational efficiency by actively modulating roll response, particularly beneficial for vessels operating in rough seas or requiring high stability standards.

Impact on Ship Design and Stability

Roll damping tanks enhance ship stability by providing active control over roll motions through internal water movement, allowing for more compact hull designs and improved fuel efficiency. Bilge keels offer passive roll reduction with minimal impact on hull form but increase hydrodynamic resistance, influencing speed and fuel consumption. Your choice between these systems affects structural layout, weight distribution, and operational performance, directly shaping overall vessel design and stability characteristics.

Energy Efficiency and Operational Costs

Roll damping tanks enhance energy efficiency by reducing the vessel's roll motions through passive water movement, resulting in lower fuel consumption compared to bilge keels. Bilge keels, while simple and cost-effective initially, create hydrodynamic drag that increases fuel usage and operational costs over time. Consequently, roll damping tanks offer a more energy-efficient solution that can lead to significant savings in long-term operational expenses.

Suitability for Different Vessel Types

Roll damping tanks are highly effective for vessels with limited beam and lower stability margins, such as luxury yachts and passenger ferries, where enhanced comfort is critical. Bilge keels are better suited for bulk carriers and tankers with wider beams, providing passive roll reduction without compromising hull form or cargo space. The choice depends on vessel size, operational profile, and stability requirements, with roll damping tanks offering active control and bilge keels providing a maintenance-free solution.

Future Trends in Ship Roll Damping Technologies

Roll damping tanks are gaining attention over bilge keels due to their ability to provide active roll stabilization without increasing hydrodynamic drag, enhancing fuel efficiency and operational performance. Advanced smart tank designs integrated with real-time sensors and automated control systems enable precise counter-roll forces tailored to varying sea conditions, outperforming traditional passive bilge keels. Your vessel's future stability will likely depend on the adoption of hybrid roll damping solutions combining tank technology with optimized bilge keel geometries for maximum effectiveness in diverse maritime environments.

Roll damping tanks vs bilge keels Infographic

libmatt.com

libmatt.com