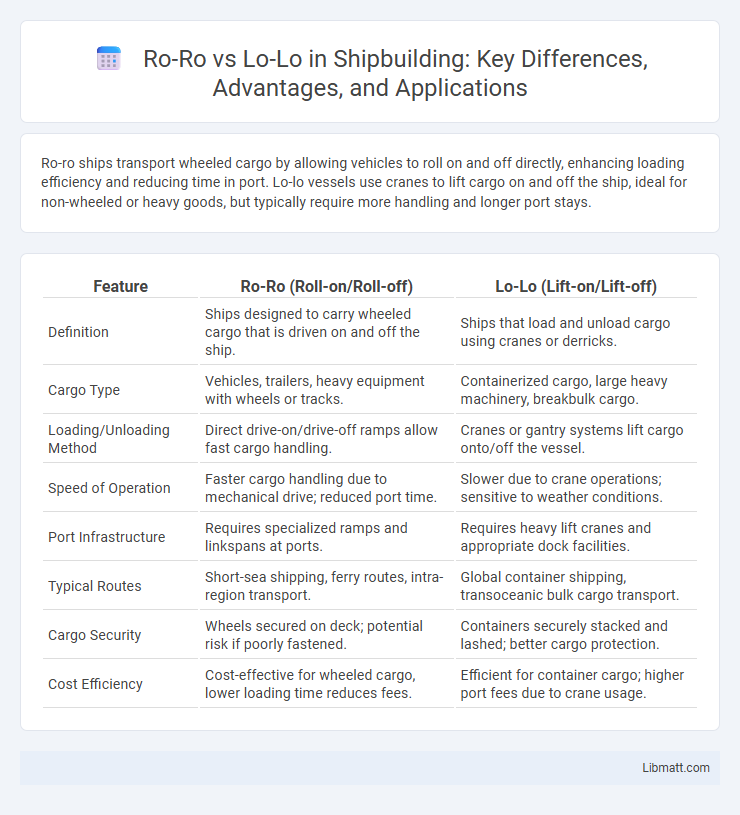

Ro-ro ships transport wheeled cargo by allowing vehicles to roll on and off directly, enhancing loading efficiency and reducing time in port. Lo-lo vessels use cranes to lift cargo on and off the ship, ideal for non-wheeled or heavy goods, but typically require more handling and longer port stays.

Table of Comparison

| Feature | Ro-Ro (Roll-on/Roll-off) | Lo-Lo (Lift-on/Lift-off) |

|---|---|---|

| Definition | Ships designed to carry wheeled cargo that is driven on and off the ship. | Ships that load and unload cargo using cranes or derricks. |

| Cargo Type | Vehicles, trailers, heavy equipment with wheels or tracks. | Containerized cargo, large heavy machinery, breakbulk cargo. |

| Loading/Unloading Method | Direct drive-on/drive-off ramps allow fast cargo handling. | Cranes or gantry systems lift cargo onto/off the vessel. |

| Speed of Operation | Faster cargo handling due to mechanical drive; reduced port time. | Slower due to crane operations; sensitive to weather conditions. |

| Port Infrastructure | Requires specialized ramps and linkspans at ports. | Requires heavy lift cranes and appropriate dock facilities. |

| Typical Routes | Short-sea shipping, ferry routes, intra-region transport. | Global container shipping, transoceanic bulk cargo transport. |

| Cargo Security | Wheels secured on deck; potential risk if poorly fastened. | Containers securely stacked and lashed; better cargo protection. |

| Cost Efficiency | Cost-effective for wheeled cargo, lower loading time reduces fees. | Efficient for container cargo; higher port fees due to crane usage. |

Introduction to Ro-Ro and Lo-Lo Shipping

Ro-Ro (Roll-on/Roll-off) shipping involves vessels designed to carry wheeled cargo such as cars, trucks, and trailers that are driven on and off the ship on their own wheels. Lo-Lo (Lift-on/Lift-off) shipping employs cranes to load and unload cargo containers, allowing for versatile handling of various goods stacked in containers. Ro-Ro is ideal for vehicles and machinery, while Lo-Lo caters to containerized freight, optimizing port operations based on cargo type.

Key Differences Between Ro-Ro and Lo-Lo Vessels

Ro-Ro vessels are designed to carry wheeled cargo such as cars, trucks, and trailers that can be driven on and off the ship, offering efficient loading and unloading processes. Lo-Lo vessels rely on cranes to lift cargo containers on and off the ship, making them suitable for standardized container shipments. Understanding these key differences helps you choose the appropriate shipping method based on cargo type, handling time, and port infrastructure.

Advantages of Ro-Ro Shipping

Ro-ro shipping offers significant advantages in efficiency by allowing entire vehicles and wheeled cargo to be driven directly onto and off the vessel, reducing cargo handling time and minimizing damage risk. This method streamlines the loading and unloading process, enhancing turnaround times and lowering labor costs compared to lo-lo (lift-on/lift-off) shipping, which relies on cranes for container handling. Ro-ro vessels provide optimal solutions for transporting cars, trucks, trailers, and heavy machinery, ensuring secure transportation with faster port operations and improved logistical flexibility.

Benefits of Lo-Lo Vessel Operations

Lo-Lo vessel operations offer precise and efficient cargo handling by utilizing cranes for loading and unloading containers, reducing dependency on port infrastructure and minimizing turnaround time. These vessels can handle a diverse range of cargo types, including heavy and oversized goods, enhancing flexibility for Your shipping needs. The ability to access ports without specialized ramps makes Lo-Lo vessels advantageous for operations in less-developed ports or remote locations.

Cargo Types Suitable for Ro-Ro and Lo-Lo

Ro-Ro ships are ideal for transporting wheeled cargo such as cars, trucks, trailers, and heavy machinery that can be driven directly on and off the vessel. Lo-Lo ships specialize in handling containerized goods, bulk cargo, and breakbulk items requiring cranes for loading and unloading. Your choice depends on whether your cargo involves self-propelled vehicles or standardized containers needing specialized equipment.

Operational Efficiency: Ro-Ro vs Lo-Lo

Ro-Ro (Roll-on/Roll-off) operations significantly enhance operational efficiency by enabling vehicles and wheeled cargo to be driven on and off vessels quickly, reducing loading and unloading time compared to Lo-Lo (Lift-on/Lift-off) methods that rely on cranes for cargo handling. Ro-Ro ships minimize port stay durations and labor costs, improving turnaround times and overall supply chain speed. In contrast, Lo-Lo operations offer flexibility for diverse cargo types but generally experience longer handling times and higher operational complexity, impacting efficiency.

Cost Comparison: Ro-Ro vs Lo-Lo

Ro-Ro shipping generally offers lower costs compared to Lo-Lo due to its efficient loading process where vehicles drive directly onto the vessel, reducing labor and port fees. Lo-Lo shipping involves lifting cargo with cranes into the vessel's hold, increasing handling expenses and turnaround time, which can elevate overall costs. Your choice depends on the type of cargo and budget, with Ro-Ro favored for wheeled goods and Lo-Lo suited for containerized or non-wheeled cargo despite higher costs.

Safety and Security Considerations

Ro-ro vessels enhance safety by minimizing cargo handling, reducing the risk of damage or accidents during loading and unloading, and securing vehicles with specialized lashing systems. Lo-lo operations involve cranes and external equipment, increasing exposure to potential equipment failure or accidents, necessitating rigorous safety protocols. Security measures on ro-ro ships focus on vehicle inspections and controlled access to ramps, whereas lo-lo cargo requires stringent monitoring of cargo units and crane operations to prevent theft or mishandling.

Environmental Impact of Ro-Ro and Lo-Lo

Ro-ro (roll-on/roll-off) ships generally have a lower environmental impact than lo-lo (lift-on/lift-off) vessels due to their efficient cargo handling, which reduces fuel consumption and emissions during loading and unloading. Ro-ro ships eliminate the need for cranes, resulting in shorter port stays and decreased energy use, contributing to lower greenhouse gas emissions. However, lo-lo vessels provide flexibility for diverse cargo types, sometimes requiring longer handling times that increase fuel usage and pollution levels at ports.

Choosing the Right Shipping Method: Factors to Consider

Choosing between Ro-ro and Lo-lo shipping methods depends on cargo type, cost efficiency, and handling needs. Ro-ro (roll-on/roll-off) is ideal for wheeled vehicles and heavy machinery, offering faster loading and unloading with minimal risk of damage. Lo-lo (lift-on/lift-off) suits containerized goods requiring secure stacking and versatile transport, especially when cargo needs protection from environmental elements.

Ro-ro vs lo-lo Infographic

libmatt.com

libmatt.com