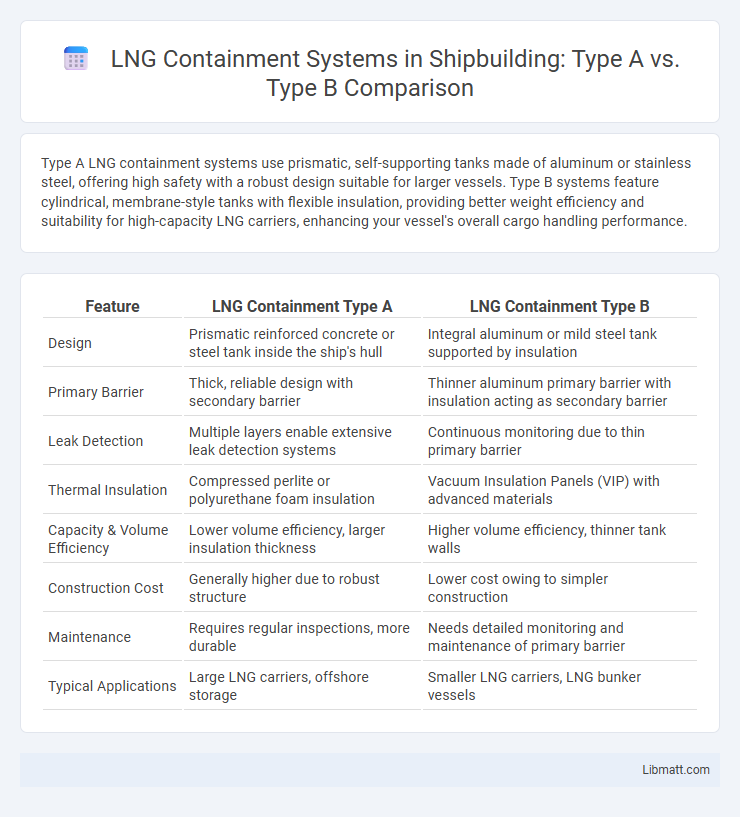

Type A LNG containment systems use prismatic, self-supporting tanks made of aluminum or stainless steel, offering high safety with a robust design suitable for larger vessels. Type B systems feature cylindrical, membrane-style tanks with flexible insulation, providing better weight efficiency and suitability for high-capacity LNG carriers, enhancing your vessel's overall cargo handling performance.

Table of Comparison

| Feature | LNG Containment Type A | LNG Containment Type B |

|---|---|---|

| Design | Prismatic reinforced concrete or steel tank inside the ship's hull | Integral aluminum or mild steel tank supported by insulation |

| Primary Barrier | Thick, reliable design with secondary barrier | Thinner aluminum primary barrier with insulation acting as secondary barrier |

| Leak Detection | Multiple layers enable extensive leak detection systems | Continuous monitoring due to thin primary barrier |

| Thermal Insulation | Compressed perlite or polyurethane foam insulation | Vacuum Insulation Panels (VIP) with advanced materials |

| Capacity & Volume Efficiency | Lower volume efficiency, larger insulation thickness | Higher volume efficiency, thinner tank walls |

| Construction Cost | Generally higher due to robust structure | Lower cost owing to simpler construction |

| Maintenance | Requires regular inspections, more durable | Needs detailed monitoring and maintenance of primary barrier |

| Typical Applications | Large LNG carriers, offshore storage | Smaller LNG carriers, LNG bunker vessels |

Overview of LNG Containment Systems

LNG containment systems are critical for safely storing and transporting liquefied natural gas at cryogenic temperatures. Type A tanks are full-penetration welded metallic tanks with a secondary barrier, offering structural integrity and ease of inspection. Type B tanks utilize a partial membrane and a primary barrier, designed with better thermal insulation and reduced weight for enhanced cargo capacity.

Introduction to Type A LNG Containment

Type A LNG containment systems use full membrane tanks with thick, reinforced insulation to safely store liquefied natural gas at cryogenic temperatures. These tanks are designed with a robust primary barrier and secondary containment to prevent leakage, making them suitable for various LNG carriers and storage applications. Understanding your LNG storage requirements helps determine if Type A containment is the most efficient and secure option.

Introduction to Type B LNG Containment

Type B LNG containment systems use self-supporting prismatic tanks with an aluminum alloy inner tank surrounded by a reinforced polyurethane foam insulation layer, providing enhanced structural integrity and thermal efficiency. Unlike Type A systems, which rely on full metallic primary barriers, Type B designs incorporate a partial secondary barrier to minimize leak risks and reduce overall weight. This containment method optimizes storage safety and durability, ensuring your LNG cargo remains secure during transport.

Structural Design Differences

Type A LNG containment systems utilize a full secondary barrier design with a primary membrane supported by insulation and a metal primary barrier structured to contain the LNG under normal and accidental conditions. Type B systems feature a self-supporting prismatic or spherical primary barrier made of stainless steel, typically without a full secondary barrier, relying on the tank's structural design and specialized insulation to control boil-off gas and maintain integrity. Structural design differences primarily include Type A's reliance on the tank's outer hull for containment and Type B's primary barrier being mechanically independent, providing enhanced resistance to thermal stresses and sloshing loads.

Material and Construction Considerations

Type A LNG containment systems utilize thick, insulated aluminum or stainless steel tanks designed for atmospheric pressure, incorporating full secondary barriers made of materials such as foam and insulation for leak prevention. Type B systems feature a self-supporting primary barrier constructed from cryogenic-grade aluminum or nickel steel alloys, optimized for low-temperature durability and thermal contraction, supported by a secondary barrier integrated within the ship's structure. Material selection in Type B containment prioritizes resistance to brittle fracture and fatigue, while Type A focuses on robust insulation and containment integrity through layered construction.

Safety Features and Risk Management

Type A LNG containment systems utilize thick, insulated steel tanks designed to withstand low pressures, offering robust mechanical integrity and enhanced protection against leaks through multiple barriers and leak detection systems. Type B containment systems feature prismatic, self-supported tanks with a primary membrane and a secondary barrier that provide improved resistance to thermal stresses and dynamic loads, enabling efficient risk management in various operational conditions. Both types incorporate advanced monitoring and emergency venting mechanisms tailored to their design, optimizing overall safety and minimizing the risk of LNG release.

Performance under Cryogenic Conditions

Type A LNG containment systems use standard carbon steel with insulation and have moderate performance under cryogenic conditions, suitable for lower pressure storage but requiring regular inspection for leak prevention. Type B containment employs specialized materials like aluminum alloys or nickel steels which offer superior thermal conductivity and structural integrity at extremely low temperatures, enhancing safety and reliability for long-term LNG storage. Your choice depends on operational pressure requirements and maintenance capabilities, with Type B providing higher performance under extreme cryogenic stress.

Inspection and Maintenance Requirements

Type A LNG containment systems require more frequent and detailed inspections due to their design involving secondary barriers and insulation materials that necessitate regular integrity checks to prevent leakage. Type B containment systems, featuring a primary barrier with enhanced structural stability, generally demand less intensive maintenance but still require routine ultrasonic testing and visual inspections to detect fatigue or cracks. Both systems mandate adherence to stringent regulatory standards and scheduled inspection intervals to ensure operational safety and efficiency.

Cost-Benefit Analysis of Type A vs Type B

Type A LNG containment systems offer lower initial construction costs due to simpler design and conventional materials, making them cost-effective for smaller to medium-sized vessels. Type B systems, while more expensive upfront because of their sophisticated insulation and partial membrane structure, provide enhanced safety, reduced boil-off rates, and longer lifespan, delivering better operational efficiency and lower maintenance costs over time. Your selection should weigh immediate budget constraints against long-term performance and risk mitigation to maximize overall value.

Suitability for Different LNG Applications

Type A LNG containment systems, featuring prismatic or cylindrical tanks with foam-infilled insulation, are suitable for small to medium-scale LNG storage and transportation, offering basic safety for stationary and floating storage units. Type B tanks use a thin, high-quality inner liner supported by a reinforced insulation system, making them ideal for larger LNG carriers and floating liquefied natural gas (FLNG) applications where weight and space optimization are critical. The choice between Type A and Type B influences design efficiency, operational reliability, and compliance with international LNG transport regulations.

LNG containment type A vs type B Infographic

libmatt.com

libmatt.com