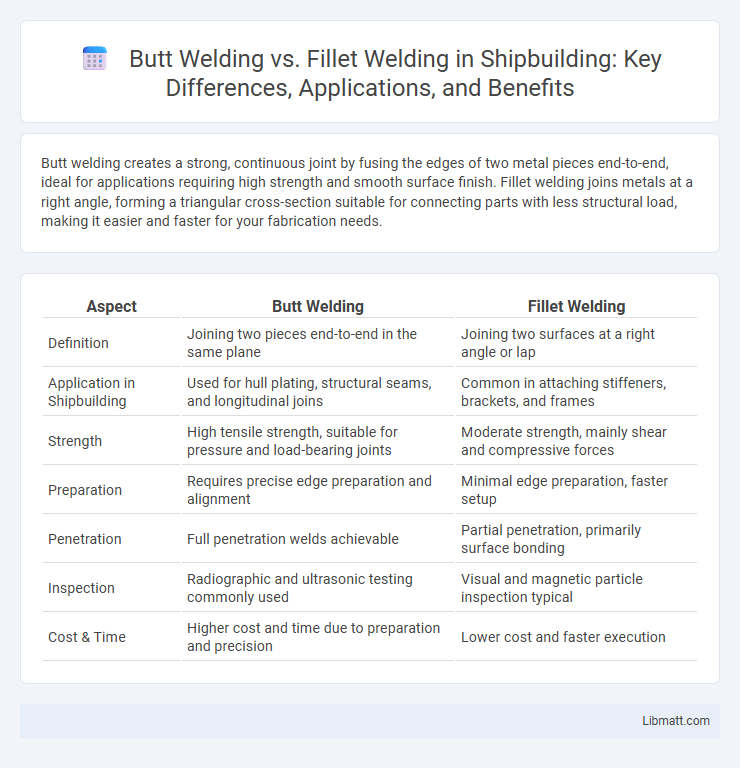

Butt welding creates a strong, continuous joint by fusing the edges of two metal pieces end-to-end, ideal for applications requiring high strength and smooth surface finish. Fillet welding joins metals at a right angle, forming a triangular cross-section suitable for connecting parts with less structural load, making it easier and faster for your fabrication needs.

Table of Comparison

| Aspect | Butt Welding | Fillet Welding |

|---|---|---|

| Definition | Joining two pieces end-to-end in the same plane | Joining two surfaces at a right angle or lap |

| Application in Shipbuilding | Used for hull plating, structural seams, and longitudinal joins | Common in attaching stiffeners, brackets, and frames |

| Strength | High tensile strength, suitable for pressure and load-bearing joints | Moderate strength, mainly shear and compressive forces |

| Preparation | Requires precise edge preparation and alignment | Minimal edge preparation, faster setup |

| Penetration | Full penetration welds achievable | Partial penetration, primarily surface bonding |

| Inspection | Radiographic and ultrasonic testing commonly used | Visual and magnetic particle inspection typical |

| Cost & Time | Higher cost and time due to preparation and precision | Lower cost and faster execution |

Introduction to Welding Techniques

Butt welding joins two pieces of metal end-to-end, creating a strong, continuous bond ideal for high-strength applications, while fillet welding joins two surfaces at a right angle, commonly used for structural joints in frameworks. Both techniques require precise heat control and skilled execution to ensure weld integrity and durability. Understanding these fundamental differences helps you select the appropriate welding method for your specific project needs.

Overview of Butt Welding

Butt welding is a welding technique where two metal pieces are joined end-to-end in the same plane, creating a continuous, strong joint ideal for structural applications. This method ensures full penetration and uniform strength, making it suitable for pipes, pressure vessels, and heavy machinery. Your project benefits from increased durability and seamless metal fusion with butt welding compared to fillet welding.

Overview of Fillet Welding

Fillet welding joins two metal surfaces at an approximate right angle, forming a triangular cross-section that provides moderate strength and ease of application. Commonly used in lap, T, and corner joints, fillet welds require less edge preparation compared to butt welding, making them faster and more cost-effective for assembling structural components. This technique supports load-bearing connections in frameworks, offering versatility across construction, shipbuilding, and industrial fabrication.

Key Differences Between Butt and Fillet Welding

Butt welding joins two metal pieces edge-to-edge, creating a flush, continuous joint ideal for high-strength applications, while fillet welding connects metals at a right-angle or lap joint, forming a triangular cross-section. The primary distinctions include joint design, load-bearing capacity, and accessibility, with butt joints offering superior strength and requiring precise alignment, whereas fillet welds are easier to perform and suited for less critical structural needs. Understanding these differences helps optimize Your welding technique based on project requirements and material type.

Applications of Butt Welding

Butt welding is extensively used in pipeline construction, structural steel fabrication, and automotive manufacturing due to its ability to create strong, continuous joints that withstand high pressure and stress. It is ideal for joining two pieces of metal end-to-end, making it essential for fabricating pressure vessels, boilers, and large steel frameworks. The technique ensures minimal distortion and superior weld integrity, which is crucial in aerospace and shipbuilding industries where safety and durability are paramount.

Applications of Fillet Welding

Fillet welding is commonly used for joining two surfaces at a right angle or lap joints, making it ideal for structural steel frameworks, shipbuilding, and automotive manufacturing. Its applications include connecting brackets, stiffeners, and other components where load distribution and ease of access are critical. You can rely on fillet welding for durable, cost-effective joints in various construction and fabrication projects.

Strength and Durability Comparison

Butt welding provides superior strength and durability by creating a continuous joint that evenly distributes stress along the welded seam, making it ideal for high-pressure and load-bearing applications. Fillet welding, while easier and faster to perform, tends to produce joints with lower tensile strength and can be more prone to fatigue and cracking under dynamic loads. Structural engineers often prefer butt welding for critical components requiring maximum integrity and longevity in demanding environments.

Cost and Efficiency Considerations

Butt welding generally offers higher efficiency and lower long-term costs due to stronger joints that require less rework and maintenance compared to fillet welding. Fillet welding typically incurs lower initial labor costs but may lead to increased expenses over time because of weaker joints that are more prone to fatigue and corrosion. Choosing between the two methods depends on project requirements, material thickness, and the need for structural integrity versus budget constraints.

Common Challenges and Solutions

Butt welding often faces challenges such as achieving proper alignment and penetration, which can be resolved by using precise fixtures and controlled heat input to ensure a strong, consistent joint. Fillet welding commonly struggles with insufficient weld throat thickness and uneven bead profiles; employing consistent welding techniques and proper electrode selection helps maintain weld integrity. Your choice between these methods should consider these typical difficulties and apply targeted solutions for optimal structural performance.

Choosing the Right Welding Method

Choosing the right welding method depends on your project's strength requirements and joint configuration; butt welding provides a strong, seamless join by fusing two pieces end-to-end, ideal for high-stress applications. Fillet welding, on the other hand, is suited for joining two surfaces at a right angle, offering ease of access and faster execution but generally less strength compared to butt welds. Assess factors like load type, accessibility, and material thickness to determine whether butt welding or fillet welding best supports your welding goals.

Butt welding vs fillet welding Infographic

libmatt.com

libmatt.com