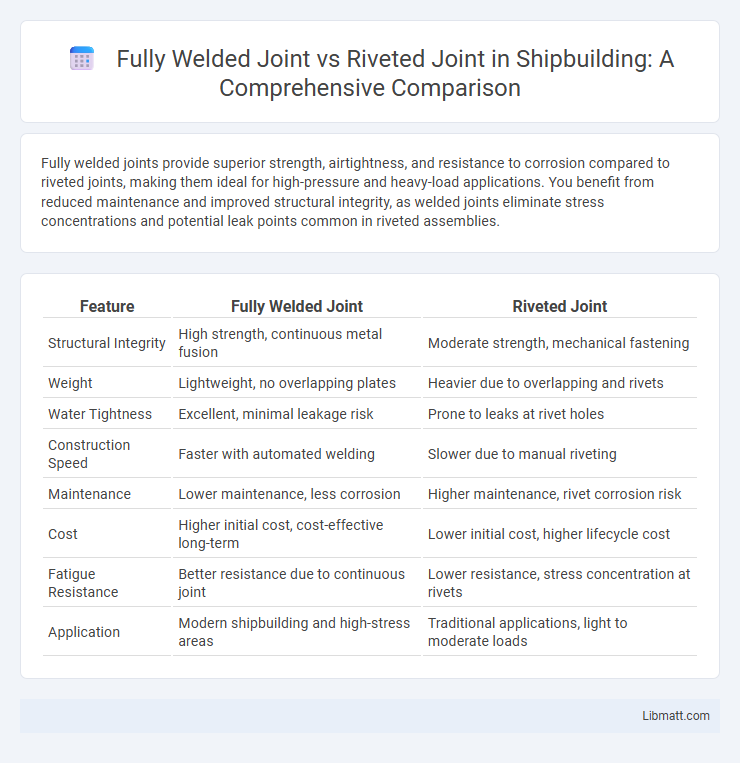

Fully welded joints provide superior strength, airtightness, and resistance to corrosion compared to riveted joints, making them ideal for high-pressure and heavy-load applications. You benefit from reduced maintenance and improved structural integrity, as welded joints eliminate stress concentrations and potential leak points common in riveted assemblies.

Table of Comparison

| Feature | Fully Welded Joint | Riveted Joint |

|---|---|---|

| Structural Integrity | High strength, continuous metal fusion | Moderate strength, mechanical fastening |

| Weight | Lightweight, no overlapping plates | Heavier due to overlapping and rivets |

| Water Tightness | Excellent, minimal leakage risk | Prone to leaks at rivet holes |

| Construction Speed | Faster with automated welding | Slower due to manual riveting |

| Maintenance | Lower maintenance, less corrosion | Higher maintenance, rivet corrosion risk |

| Cost | Higher initial cost, cost-effective long-term | Lower initial cost, higher lifecycle cost |

| Fatigue Resistance | Better resistance due to continuous joint | Lower resistance, stress concentration at rivets |

| Application | Modern shipbuilding and high-stress areas | Traditional applications, light to moderate loads |

Introduction to Fully Welded and Riveted Joints

Fully welded joints provide a continuous metal fusion, resulting in high strength and airtight seals favored in modern construction and manufacturing. Riveted joints rely on mechanical fastening with rivets, offering durability and resistance to fatigue in traditional steel structures and bridges. Understanding these differences helps you choose the optimal joint type for your specific engineering or construction project.

Defining Fully Welded Joints

Fully welded joints are permanent connections created by melting base metals together along the joint interface, resulting in a continuous, uniform bond with no gaps or overlaps. These joints offer superior strength, airtightness, and resistance to corrosion compared to riveted joints, which rely on mechanical fasteners such as rivets. Commonly used in high-stress or pressure-containing applications, fully welded joints enhance structural integrity and reduce maintenance requirements.

Understanding Riveted Joints

Riveted joints consist of metal plates joined by metal pins or rivets heated and hammered to form permanent connections, widely used in bridge construction and shipbuilding for their high shear strength and resistance to vibration. Unlike fully welded joints, riveted joints accommodate slight movements and thermal expansion without cracking, making them suitable for dynamic structures. However, riveted joints require more labor and inspection compared to welding, impacting construction time and maintenance costs.

Structural Performance Comparison

Fully welded joints exhibit superior structural performance compared to riveted joints due to their continuous metal fusion, resulting in higher load-bearing capacity and enhanced resistance to shear and tensile stresses. Welded joints provide uniform stress distribution and improved fatigue strength, reducing the likelihood of joint failure under dynamic or cyclic loading. Riveted joints, while easier to inspect and maintain, usually demonstrate lower strength and increased susceptibility to stress concentration and corrosion at fastener points.

Durability and Maintenance Factors

Fully welded joints offer superior durability compared to riveted joints due to their continuous metal fusion, resulting in higher strength and resistance to fatigue and corrosion. Riveted joints require regular maintenance, including inspection for loose or damaged rivets and potential leakages, while welded joints typically need less frequent upkeep, reducing long-term maintenance costs. Ensuring Your structures use fully welded joints can enhance longevity and decrease maintenance intervals, optimizing overall performance.

Cost Analysis: Welding vs Riveting

Fully welded joints typically have higher upfront costs due to specialized equipment and skilled labor requirements, but they offer reduced long-term maintenance and increased structural integrity compared to riveted joints. Riveted joints involve lower initial costs and simpler tools, yet they often lead to longer assembly times and potential future expenses related to joint loosening or corrosion. Your choice between welding and riveting can impact overall project budget efficiency, balancing immediate expenditure against durability and lifecycle costs.

Application Areas and Industry Preferences

Fully welded joints are preferred in automotive and aerospace industries due to their superior strength, leak-proof nature, and ability to withstand high stress and vibration, making them ideal for structural and pressure-containing applications. Riveted joints remain popular in construction and railway industries for their ease of inspection, repair, and tolerance to dynamic loads, especially in assembling large steel frameworks and bridges. Industry preferences shift towards welding when seamless integration and lightweight design are critical, while riveting is favored where field repairs and component disassembly are frequent.

Safety and Reliability Considerations

Fully welded joints provide superior safety and reliability by creating a continuous, uniform bond that resists stress, fatigue, and corrosion better than riveted joints. Riveted joints, while historically trusted, may develop loosening or fatigue cracks under dynamic loads, posing potential safety risks over time. Ensuring your structures use fully welded joints enhances durability and minimizes maintenance needs for critical applications.

Environmental Impact Assessment

Fully welded joints create a more airtight and watertight seal, reducing potential leaks and minimizing environmental contamination compared to riveted joints, which may have small gaps prone to corrosion and leaks over time. The use of welding reduces maintenance frequency and the associated environmental costs, while riveted joints often require more frequent inspections and repairs, increasing resource consumption. Choosing a fully welded joint for Your projects can lead to a lower overall environmental impact through enhanced durability and reduced risk of pollutant release.

Conclusion: Choosing the Right Joint Type

Fully welded joints provide superior strength, airtightness, and corrosion resistance compared to riveted joints, making them ideal for high-pressure and critical structural applications. Riveted joints, however, offer easier assembly and inspection, suitable for vintage machinery or where flexibility and repairability are prioritized. Your choice depends on factors such as load requirements, environmental conditions, maintenance needs, and fabrication capabilities.

Fully welded joint vs riveted joint Infographic

libmatt.com

libmatt.com