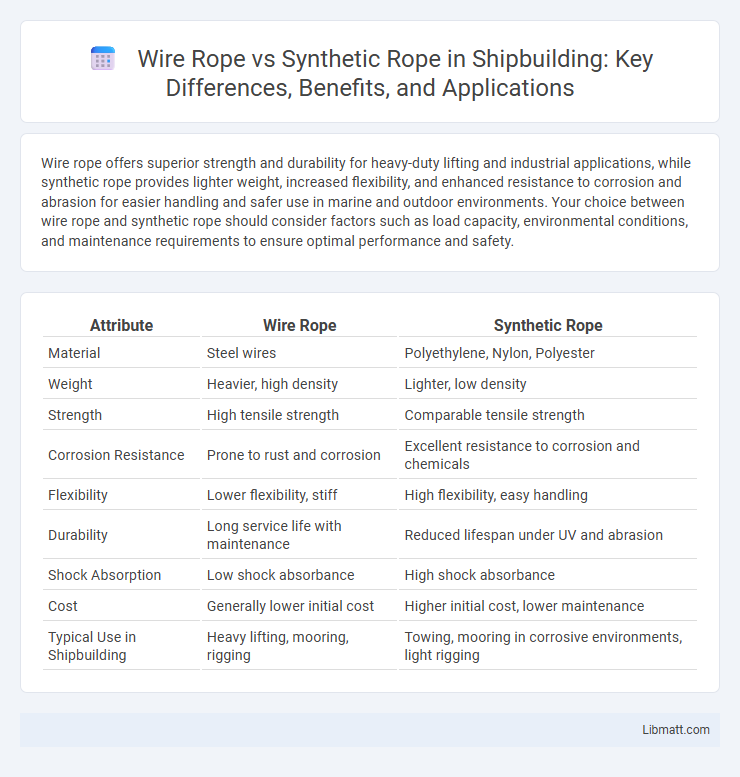

Wire rope offers superior strength and durability for heavy-duty lifting and industrial applications, while synthetic rope provides lighter weight, increased flexibility, and enhanced resistance to corrosion and abrasion for easier handling and safer use in marine and outdoor environments. Your choice between wire rope and synthetic rope should consider factors such as load capacity, environmental conditions, and maintenance requirements to ensure optimal performance and safety.

Table of Comparison

| Attribute | Wire Rope | Synthetic Rope |

|---|---|---|

| Material | Steel wires | Polyethylene, Nylon, Polyester |

| Weight | Heavier, high density | Lighter, low density |

| Strength | High tensile strength | Comparable tensile strength |

| Corrosion Resistance | Prone to rust and corrosion | Excellent resistance to corrosion and chemicals |

| Flexibility | Lower flexibility, stiff | High flexibility, easy handling |

| Durability | Long service life with maintenance | Reduced lifespan under UV and abrasion |

| Shock Absorption | Low shock absorbance | High shock absorbance |

| Cost | Generally lower initial cost | Higher initial cost, lower maintenance |

| Typical Use in Shipbuilding | Heavy lifting, mooring, rigging | Towing, mooring in corrosive environments, light rigging |

Introduction to Wire Rope and Synthetic Rope

Wire rope consists of multiple strands of metal wire twisted together for high strength, durability, and resistance to abrasion, making it ideal for heavy lifting and industrial applications. Synthetic rope, made from ultra-high-molecular-weight polyethylene or nylon fibers, offers lightweight flexibility, excellent corrosion resistance, and superior shock absorption. Your choice between wire rope and synthetic rope depends on the specific requirements of strength, weight, and environmental conditions.

Material Composition and Construction

Wire rope consists of steel wires twisted into strands, then braided into a helix, offering high tensile strength and durability essential for heavy lifting and industrial applications. Synthetic rope is made from high-performance fibers such as nylon, polyester, or Dyneema, providing lightweight, flexibility, and resistance to corrosion and abrasion. Your choice depends on the specific demands of strength, weight, and environmental exposure, where wire rope excels in load capacity and synthetic rope in versatility and ease of handling.

Strength and Load-Bearing Capacity

Wire rope offers superior strength and higher load-bearing capacity compared to synthetic rope, making it ideal for heavy-duty lifting and industrial applications. Synthetic ropes, while lighter and more flexible, typically have lower tensile strength but provide excellent shock absorption and resistance to corrosion. Choosing between wire rope and synthetic rope depends on specific load requirements, environmental conditions, and safety factors.

Durability and Lifespan Comparisons

Wire rope offers superior durability with high tensile strength and resistance to abrasion, corrosion, and heat, often lasting several years under heavy-duty conditions. Synthetic rope, typically made from materials like polyester or nylon, provides excellent flexibility and shock absorption but generally has a shorter lifespan due to UV exposure, moisture, and chemical degradation. Proper maintenance and environmental factors heavily influence the longevity of both wire and synthetic ropes, making usage context critical in lifespan comparisons.

Weight and Handling Differences

Wire rope offers significantly higher weight compared to synthetic rope, making handling more labor-intensive and requiring specialized equipment for lifting and maneuvering. Synthetic ropes are lightweight, enhancing ease of handling, reducing fatigue, and improving safety during installation or retrieval. The distinct weight differences affect operational efficiency, with synthetic ropes providing better ergonomics in dynamic applications.

Safety Considerations and Risks

Wire rope offers superior resistance to abrasion and high tensile strength, making it ideal for heavy lifting tasks with reduced risk of sudden failure; however, it is susceptible to corrosion and fatigue cracks that require regular inspection to prevent accidents. Synthetic rope provides enhanced flexibility, lighter weight, and better shock absorption but presents higher vulnerability to UV damage, chemical exposure, and abrasion, increasing the risk of unexpected breaks if not properly maintained. Ensuring safety depends on frequent inspection, environment-specific rope selection, and adherence to load ratings tailored to the rope material's strengths and weaknesses.

Maintenance and Care Requirements

Wire ropes require regular lubrication to prevent corrosion and reduce friction, with frequent inspections for broken strands or kinks essential to ensure safety and longevity. Synthetic ropes demand less maintenance but must be regularly cleaned to remove dirt and chemicals, and stored away from UV exposure and moisture to prevent degradation. Both types benefit from routine checks, but synthetic ropes offer easier handling with lower overall upkeep.

Cost Analysis: Wire vs Synthetic Rope

Wire rope typically has a higher initial cost compared to synthetic rope, but its durability and resistance to abrasion can lead to lower long-term expenses in heavy-duty applications. Synthetic rope offers cost advantages with lighter weight, easier handling, and reduced equipment wear, which can decrease operational costs and improve safety for Your projects. Consider the total lifecycle cost of each option, including maintenance, replacement frequency, and specific use conditions, to make an informed decision.

Applications and Use Cases

Wire rope excels in heavy-duty applications such as construction, mining, and marine environments due to its high tensile strength and resistance to abrasion. Synthetic rope offers superior flexibility, lighter weight, and enhanced resistance to corrosion, making it ideal for climbing, rescue operations, and sailing. Your choice depends on the specific use case requirements, including load capacity, environmental conditions, and handling preferences.

Choosing the Right Rope for Your Needs

Selecting the right rope depends on factors like strength, weight, durability, and environmental conditions. Wire rope offers superior abrasion resistance and higher tensile strength, making it ideal for heavy lifting and industrial applications. Your choice may lean towards synthetic rope if you require lightweight, flexible handling with resistance to corrosion and UV damage in marine or rescue scenarios.

Wire rope vs synthetic rope Infographic

libmatt.com

libmatt.com