Hydroextraction uses water pressure to remove moisture, making it energy-efficient and gentle on delicate fabrics, while centrifuging employs rapid spinning to force water out, offering faster drying but potentially stressing materials. You can choose hydroextraction for fabric care and energy savings or centrifuging for speed and convenience.

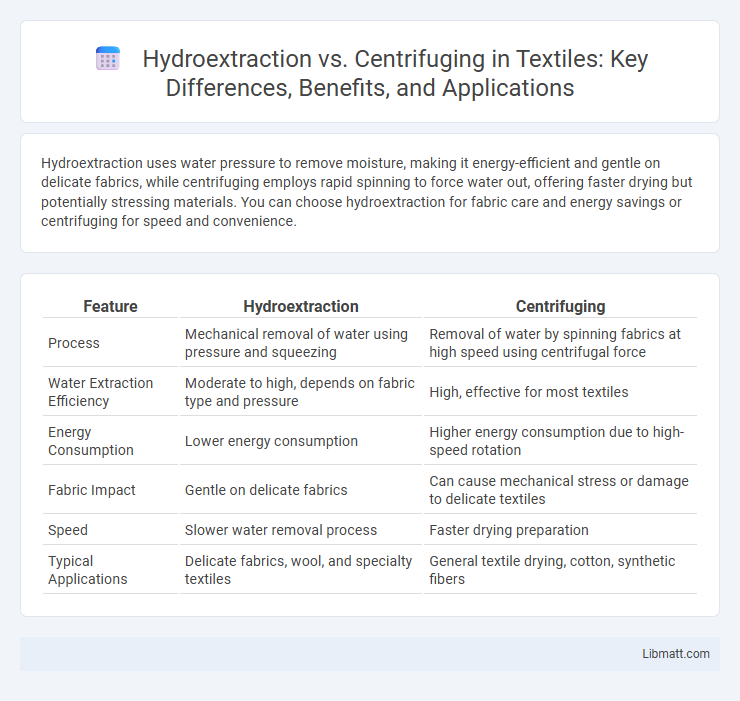

Table of Comparison

| Feature | Hydroextraction | Centrifuging |

|---|---|---|

| Process | Mechanical removal of water using pressure and squeezing | Removal of water by spinning fabrics at high speed using centrifugal force |

| Water Extraction Efficiency | Moderate to high, depends on fabric type and pressure | High, effective for most textiles |

| Energy Consumption | Lower energy consumption | Higher energy consumption due to high-speed rotation |

| Fabric Impact | Gentle on delicate fabrics | Can cause mechanical stress or damage to delicate textiles |

| Speed | Slower water removal process | Faster drying preparation |

| Typical Applications | Delicate fabrics, wool, and specialty textiles | General textile drying, cotton, synthetic fibers |

Introduction to Moisture Removal Techniques

Moisture removal techniques such as hydroextraction and centrifuging are essential in industries like textiles, food processing, and wastewater treatment to efficiently reduce water content and improve product quality. Hydroextraction uses pressure and mechanical forces to extract moisture by squeezing materials, while centrifuging employs rapid spinning to separate water through centrifugal force. Choosing between these methods depends on factors like the material type, moisture level, and processing speed requirements.

Understanding Hydroextraction

Hydroextraction is a method used to remove water from materials by applying centrifugal force, efficiently separating liquids from solids and reducing moisture content significantly. This technique is often preferred in industrial applications for its energy efficiency and ability to handle large volumes compared to traditional drying methods. Understanding hydroextraction involves recognizing its role in enhancing process speed and product quality by minimizing residual water without excessive heat exposure.

Principles of Centrifuging

Centrifuging operates on the principle of centrifugal force, which rapidly spins a container to separate substances of different densities. During this process, heavier particles move outward to the container's perimeter, while lighter components remain closer to the center. Understanding this principle can help you optimize separation efficiency in various industrial and laboratory applications.

Key Differences Between Hydroextraction and Centrifuging

Hydroextraction uses high-speed spinning to remove water by applying centrifugal force, making it highly efficient for drying fabrics quickly. Centrifuging, while similar in utilizing centrifugal force, often operates at varying speeds and is widely applied across industries to separate liquids from solids or denser materials from lighter ones. Your choice between hydroextraction and centrifuging depends on the desired drying speed and the specific separation requirements.

Efficiency Comparison: Hydroextraction vs Centrifuging

Hydroextraction offers higher water removal efficiency compared to centrifuging, resulting in faster drying times and reduced energy consumption. Centrifuging operates at high rotational speeds to separate water but often retains more moisture, making hydroextraction preferable for industries demanding optimal moisture reduction. Your choice between these methods impacts overall process efficiency and operational costs significantly.

Applications in Industry: Where Each Method Excels

Hydroextraction excels in industries requiring efficient moisture removal from delicate materials such as textiles and agricultural products due to its gentle pressure application, preserving fiber integrity and reducing drying times. Centrifuging is preferred in wastewater treatment and chemical processing for rapid phase separation, thanks to its high-speed rotational force that effectively separates solids from liquids in viscous or heterogeneous mixtures. Both methods optimize industrial moisture management but target different material consistencies and processing needs, with hydroextraction favoring fragile substrates and centrifuging handling robust, particulate-laden fluids.

Energy Consumption and Environmental Impact

Hydroextraction generally consumes less energy than centrifuging, as it uses mechanical pressure to remove water without relying on high-speed motors, reducing electricity demand. Environmental impact is lower in hydroextraction due to decreased energy usage and minimal wear on fabrics, leading to less frequent replacement and waste generation. Centrifuging, while effective for rapid water removal, often results in higher carbon emissions and increased operational costs tied to its intensive power consumption.

Advantages and Limitations of Hydroextraction

Hydroextraction offers advantages such as gentle removal of water from delicate fabrics, resulting in less damage and extended textile lifespan compared to centrifuging. It also reduces energy consumption by utilizing water pressure instead of high-speed spinning, making it more environmentally friendly. However, hydroextraction is limited by slower drying times and higher initial equipment costs, which may affect its suitability for large-scale or time-sensitive operations.

Pros and Cons of Centrifuging

Centrifuging offers rapid and efficient water removal from materials, making it ideal for industrial-scale applications requiring quick drying cycles. However, the high-speed spinning can cause mechanical stress, potentially damaging delicate fibers and increasing energy consumption compared to hydroextraction. Your choice should balance the need for speed and thoroughness against the risk of material wear and higher operational costs.

Selecting the Right Moisture Removal Method

Choosing between hydroextraction and centrifuging for moisture removal depends on factors such as fabric type, desired drying speed, and energy efficiency. Hydroextraction uses high-pressure water removal, ideal for delicate textiles needing gentle treatment, while centrifuging applies rapid spinning to extract water quickly from denser materials. Evaluating equipment cost, cycle time, and residual moisture levels ensures optimal method selection for industrial or household laundry applications.

Hydroextraction vs Centrifuging Infographic

libmatt.com

libmatt.com