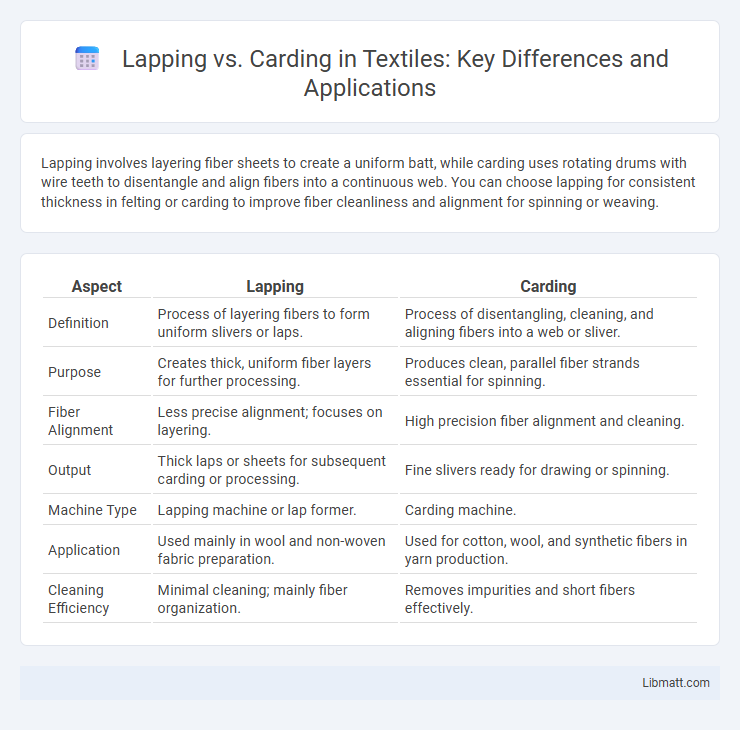

Lapping involves layering fiber sheets to create a uniform batt, while carding uses rotating drums with wire teeth to disentangle and align fibers into a continuous web. You can choose lapping for consistent thickness in felting or carding to improve fiber cleanliness and alignment for spinning or weaving.

Table of Comparison

| Aspect | Lapping | Carding |

|---|---|---|

| Definition | Process of layering fibers to form uniform slivers or laps. | Process of disentangling, cleaning, and aligning fibers into a web or sliver. |

| Purpose | Creates thick, uniform fiber layers for further processing. | Produces clean, parallel fiber strands essential for spinning. |

| Fiber Alignment | Less precise alignment; focuses on layering. | High precision fiber alignment and cleaning. |

| Output | Thick laps or sheets for subsequent carding or processing. | Fine slivers ready for drawing or spinning. |

| Machine Type | Lapping machine or lap former. | Carding machine. |

| Application | Used mainly in wool and non-woven fabric preparation. | Used for cotton, wool, and synthetic fibers in yarn production. |

| Cleaning Efficiency | Minimal cleaning; mainly fiber organization. | Removes impurities and short fibers effectively. |

Introduction to Lapping and Carding

Lapping and carding are essential processes in textile manufacturing used to prepare fibers for spinning. Lapping involves layering fibers into a continuous, uniform web or lap, ensuring consistent thickness and texture, while carding separates and aligns fibers to form a thin sliver by removing impurities and short fibers. Your understanding of these methods helps optimize fiber quality and improve yarn production efficiency.

Definition of Lapping

Lapping is a textile process that involves layering fibers or yarns in a continuous movement to form a web or batt, often used as a preparatory step before carding. This technique ensures uniform fiber distribution, enhancing the final fabric's strength and texture. In contrast, carding disentangles, cleans, and aligns fibers, preparing them for spinning.

Definition of Carding

Carding is a mechanical process that disentangles, cleans, and aligns fibers to produce a continuous web or sliver suitable for further textile manufacturing steps. This technique separates and organizes raw fibers such as cotton, wool, or synthetic material by passing them through a series of rotating drums covered with fine wire teeth. You can distinguish carding from lapping, which primarily involves flattening and layering fibers into uniform sheets instead of aligning individual fibers.

Key Differences Between Lapping and Carding

Lapping involves layering fibers to create a uniform batt, ensuring consistent thickness and density, while carding aligns and separates fibers into a web or sliver, optimizing fiber orientation for subsequent processes. Lapping is mainly used to produce thicker fiber sheets suitable for insulation or padding, whereas carding prepares fibers for spinning or felting by enhancing fiber clean-up and alignment. The primary difference lies in lapping's role in consolidating fibers versus carding's focus on fiber separation and alignment.

Purpose and Applications of Lapping

Lapping is a precision surface finishing process designed to achieve extremely flat and smooth finishes on metal, glass, and semiconductor materials, essential in manufacturing high-precision components like optical lenses and engine parts. Carding, in contrast, primarily processes fibrous materials such as cotton and wool to align fibers for textile production rather than surface finishing. Your choice of lapping ensures superior tolerance control and surface quality critical in aerospace, automotive, and electronics industries.

Purpose and Applications of Carding

Carding is a key textile process designed to disentangle, clean, and align fibers into a continuous web or sliver, preparing them for further processing like spinning or roving. It serves to remove impurities and short fibers while enhancing uniform fiber distribution, which improves yarn quality and strength. Common applications of carding include cotton, wool, and synthetic fiber production in industries like apparel manufacturing, home textiles, and nonwoven fabric creation.

Process Steps in Lapping

Lapping involves abrading two surfaces with an abrasive slurry between them, requiring multiple precise steps: surface preparation, abrasive application, controlled pressure, and rotational or reciprocal motion to achieve a smooth, flat finish. This process ensures uniform material removal and high-quality surface textures critical for automotive, aerospace, and semiconductor components. Carding, in contrast, primarily aligns fibers in textile production rather than refining surface finishes.

Process Steps in Carding

Carding involves feeding fiber into a carding machine where rotating drums covered with fine wire teeth open, clean, and align the fibers into a thin web or sliver. This process breaks up clumps, removes impurities, and forms a continuous, uniform fiber layer necessary for subsequent textile manufacturing steps. Unlike lapping, which primarily rolls fibers into loose sheets, carding transforms raw fibers into aligned, disentangled strands crucial for spinning.

Advantages and Disadvantages of Lapping vs Carding

Lapping offers precise layering with minimal defects, making it ideal for creating uniform textile webs, but it is slower and less versatile than carding. Carding excels in fiber separation and cleaning, enabling higher production speeds and better fiber alignment, though it may introduce more neps and unevenness. Choosing between lapping and carding depends on factors like desired fabric quality, production efficiency, and specific fiber characteristics.

Choosing Between Lapping and Carding: Factors to Consider

Choosing between lapping and carding depends on material type, desired fiber alignment, and end-use application. Lapping is ideal for producing uniformly layered webs in nonwoven textiles, enhancing bulk and strength, while carding excels in fiber separation and individualization, suitable for creating smoother yarns and fabrics. Key factors include fiber length, production volume, and product texture requirements to optimize manufacturing efficiency and quality.

Lapping vs Carding Infographic

libmatt.com

libmatt.com