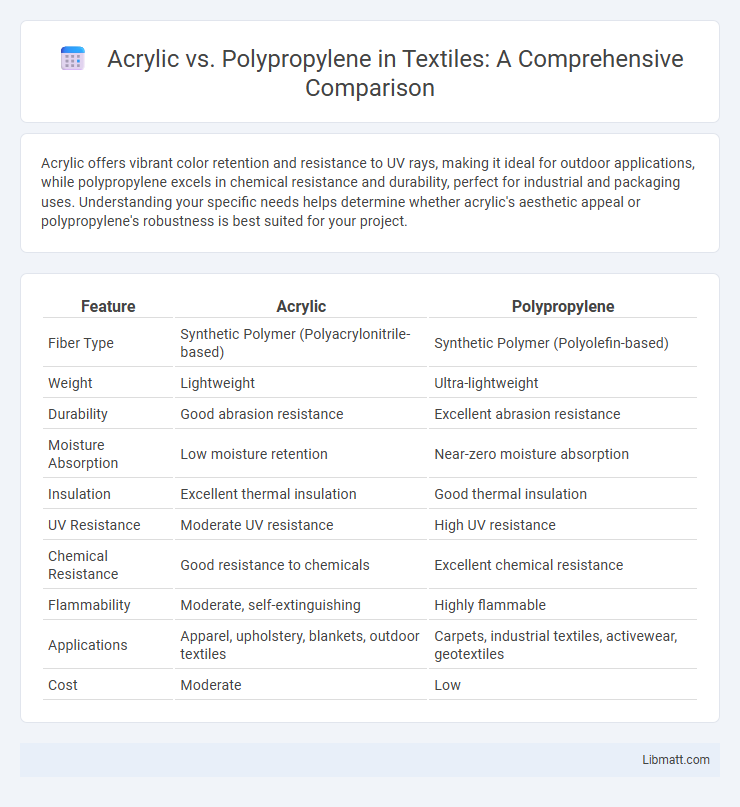

Acrylic offers vibrant color retention and resistance to UV rays, making it ideal for outdoor applications, while polypropylene excels in chemical resistance and durability, perfect for industrial and packaging uses. Understanding your specific needs helps determine whether acrylic's aesthetic appeal or polypropylene's robustness is best suited for your project.

Table of Comparison

| Feature | Acrylic | Polypropylene |

|---|---|---|

| Fiber Type | Synthetic Polymer (Polyacrylonitrile-based) | Synthetic Polymer (Polyolefin-based) |

| Weight | Lightweight | Ultra-lightweight |

| Durability | Good abrasion resistance | Excellent abrasion resistance |

| Moisture Absorption | Low moisture retention | Near-zero moisture absorption |

| Insulation | Excellent thermal insulation | Good thermal insulation |

| UV Resistance | Moderate UV resistance | High UV resistance |

| Chemical Resistance | Good resistance to chemicals | Excellent chemical resistance |

| Flammability | Moderate, self-extinguishing | Highly flammable |

| Applications | Apparel, upholstery, blankets, outdoor textiles | Carpets, industrial textiles, activewear, geotextiles |

| Cost | Moderate | Low |

Introduction: Understanding Acrylic and Polypropylene

Acrylic, a transparent thermoplastic known for its glass-like clarity and weather resistance, is widely used in signage, displays, and protective barriers. Polypropylene, a versatile polymer characterized by its chemical resistance, flexibility, and toughness, finds applications in packaging, automotive parts, and textiles. Understanding these materials' unique properties helps optimize their use in diverse industrial and consumer products.

Chemical Composition and Structure

Acrylic, composed of polymethyl methacrylate (PMMA), features a rigid, transparent structure formed from methyl methacrylate monomers, offering excellent clarity and UV resistance. Polypropylene consists of long hydrocarbon chains with a crystalline structure, making it more flexible and resistant to chemical solvents, acids, and bases. Your choice depends on whether you prioritize the optical clarity and rigidity of acrylic or the chemical resistance and flexibility of polypropylene.

Durability and Longevity Comparison

Acrylic offers moderate durability with good resistance to weathering and UV exposure, making it suitable for outdoor applications but prone to scratching over time. Polypropylene exhibits superior impact resistance and exceptional chemical resistance, contributing to its longevity in demanding environments and frequent handling. When comparing longevity, polypropylene generally outperforms acrylic due to its enhanced toughness and resilience against stress and environmental factors.

Cost Differences: Acrylic vs Polypropylene

Acrylic typically costs more than polypropylene due to its higher clarity and superior weather resistance, making it ideal for applications requiring aesthetic appeal and durability. Polypropylene is more affordable, offering excellent chemical resistance and flexibility, which suits budget-conscious projects or those needing impact resistance. Choosing between acrylic and polypropylene depends on balancing material performance with cost constraints in specific applications.

Applications and Common Uses

Acrylic is widely used in display cases, signage, and aquariums due to its clarity, weather resistance, and ease of fabrication. Polypropylene finds common applications in packaging, automotive parts, and reusable containers because of its chemical resistance, durability, and low cost. Your choice between acrylic and polypropylene should consider the specific demands of your application, such as transparency needs or exposure to chemicals.

Environmental Impact and Sustainability

Acrylic and polypropylene differ significantly in environmental impact and sustainability, with acrylic being a petroleum-based plastic that releases toxic fumes during production and is less biodegradable, contributing to long-term pollution. Polypropylene, also derived from fossil fuels, offers better recycling rates and lower energy consumption in manufacturing, making it a more sustainable choice for eco-conscious consumers. Your choice can influence waste reduction efforts and carbon footprint management, favoring polypropylene for a greener alternative.

Maintenance and Cleaning Requirements

Acrylic surfaces require gentle cleaning with mild soap and water to avoid scratching, and harsh chemicals can cause discoloration or damage. Polypropylene is more resistant to stains and chemicals, making it easier to maintain with standard household cleaners without risk of damage. By choosing polypropylene, you can reduce your cleaning effort while ensuring long-term durability and appearance.

Appearance and Design Flexibility

Acrylic offers superior clarity and vibrant color options, making it ideal for applications where a glass-like appearance and high aesthetic appeal are crucial. Polypropylene provides excellent design flexibility with its ability to be easily molded into complex shapes while maintaining durability and chemical resistance. Understanding these differences helps you select the best material for projects requiring either premium visual quality or versatile, lightweight construction.

Performance in Varying Conditions

Acrylic maintains its clarity and color stability under UV exposure and cold temperatures, making it ideal for outdoor applications and harsh environments. Polypropylene excels in chemical resistance and flexibility, especially at low temperatures, ensuring durability in industrial and automotive uses. Both materials offer distinct performance benefits, with acrylic favored for visual clarity and polypropylene for mechanical resilience in varying conditions.

Which Material Is Best: Final Verdict

Acrylic offers superior clarity, UV resistance, and scratch durability, making it ideal for applications requiring visual appeal and longevity. Polypropylene excels in chemical resistance, flexibility, and cost-effectiveness, suitable for practical uses where durability against solvents and impact is critical. Your choice depends on whether optical quality and aesthetics (Acrylic) or chemical resilience and affordability (Polypropylene) align better with your project needs.

Acrylic vs Polypropylene Infographic

libmatt.com

libmatt.com